Estimated reading time: 11 minutes

Scaling fulfillment volume in a warehouse almost always means having to automate at least some tasks. But automating doesn’t have to be an “all or nothing” proposition. There are often a number of small, easy ways to begin automating fulfillment that provide an ROI faster and allow your operation to scale.

The first step, of course, is to recognize that your operations are in fact due for a change. The cost and scope of automation systems mean that they should be implemented purposefully, for the right reasons, and in the right places. Here we look at what signals that a warehouse is ready, and offer some practical advice about where to start.

Busting Some Automation Myths: Is Your Warehouse Ready For Fulfillment Automation

The hesitancy to automate often stems from assumptions that are outdated or taken out of context. Take, for example, the idea that an increase in automation means a corresponding decrease in jobs. Nowadays, it’s widely accepted that automation can create jobs. It may, however, realign manual and physical tasks to those requiring planning, critical thinking, and problem-solving skills.

Other myths about automation include:

Myth 1: “Automation is Too Expensive for Our Business” It’s a common belief that automation requires a significant upfront investment, making it inaccessible for smaller businesses. However, automation doesn’t always mean high costs. With scalable solutions like the Sprinter™ offers a low entry point, taking the burden off pack/ship staff and allowing them to focus on higher-value tasks. The return on investment (ROI) often outweighs the initial costs, especially when automation reduces labor costs, improves efficiency, and eliminates human error. Plus, the Sprinter™ is an affordable entry-level system that sets the bar for fulfillment speed, achieving up to 15 CPM (7,200 parcels) in an 8-hour shift. Many automation solutions, including the Sprinter™, are designed to fit a wide range of budgets, making automation more accessible for businesses of all sizes.

“Adding the sprinter has allowed us to increase productivity and accuracy while reducing the amount of labor required per package.”

– Andrew Mulder, Warehouse Manager, Holland Bulb Farms

Myth 2: “Automation is Too Complicated to Implement” Some businesses worry that automation is too complex or requires a complete overhaul of their current operations. In reality, automation can be customized to fit a business’s specific needs without the need for a full transformation. At StreamTech, we take the guesswork out of the process with our Applications Engineering service. We scope out each element of your operations, studying your data, analyzing operational challenges, and assessing your package profiles. Our team does the heavy lifting by designing, drawing, and providing a workable solution tailored to your business. You don’t have to worry about understanding the complexities of material handling automation—we do that for you, ensuring you get a seamless and effective automation solution that evolves as your business grows.

Myth 3: “We Don’t Have the IT Infrastructure for Automation” Many small businesses worry that they lack the IT infrastructure needed to support automation. However, automation today is often designed to be simple to implement, even without advanced IT systems. StreamTech has a team of software engineers who work closely with your IT team to scope out the software interface connection, using standard protocols such as API connections, database or directory sharing, or simply a daily data import. We do the heavy lifting to simplify this complexity, ensuring a smooth integration. While cloud-based solutions and plus-and-play systems make automation more accessible, it’s important to note that your IT team plays a crucial role in this process. We collaborate with them to make the integration as seamless as possible, providing the support needed to implement these tools and ensure they work efficiently within your existing infrastructure.

Myth 4: “What if the Automation System Breaks Down?” Some businesses fear that automation systems will break down, leading to costly downtime and operational disruptions. While there’s always a risk of technical issues, automation systems are generally reliable, and modern systems are designed with redundancy and backup solutions to minimize downtime. All devices in these systems communicate with our Warehouse Control Software (WCS), which is installed on a PC within the system. The WCS tracks the status of each device and reports this information to the PLC in the control panel. In the event of a fault, our system can alert your operators to the precise location of the problem, enabling quick resolution. Additionally, we can perform remote troubleshooting over the phone to solve issues promptly. To further ensure smooth operations, we also train one of your operators as a “system expert,” so they have a solid understanding of the basics needed to troubleshoot the system. Regular maintenance and a clear support system in place can significantly reduce the chances of major disruptions, and it’s important to note that manual processes also carry risks of error and inefficiency—automation helps reduce those risks over time.

Signs Your Warehouse Is Ready For Automation

Once you’re open to the concept of adding automation, the next step is deciding whether or not your operation is ready. Here are seven telltale signs that your manual methods are no longer cutting it and are likely holding your business back.

1. Your Product Offering Has Grown

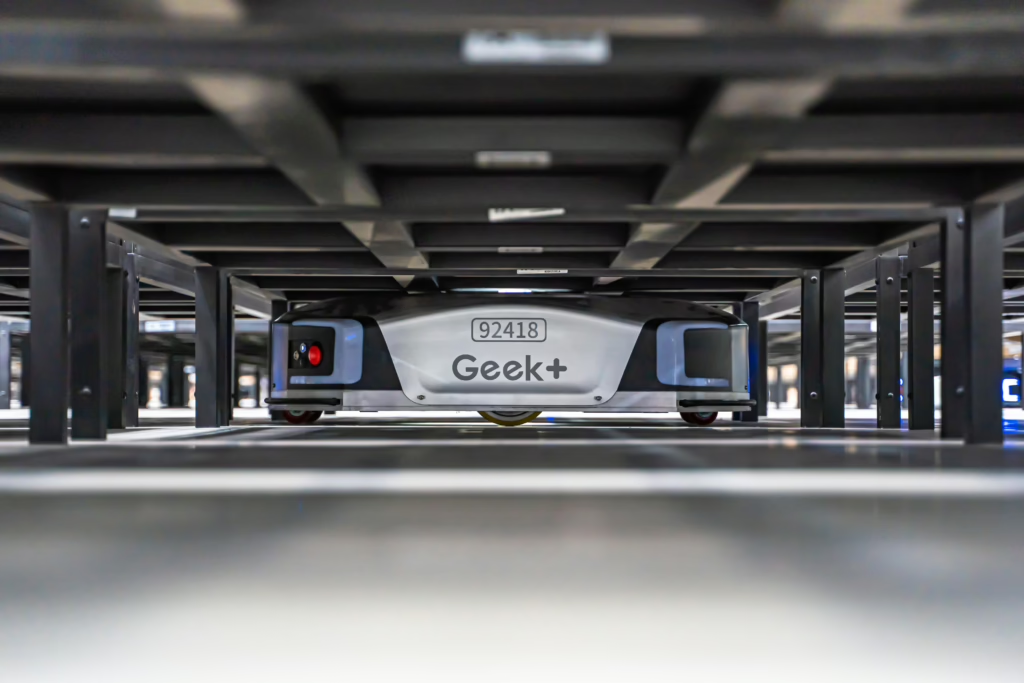

As your product offerings grow, your picking will become more complex. Your pack process will also become more complex for your warehouse staff as they decide which box for each order. Picking automation as well as end of line SLAM shipping automation will aid in this transition, so the operators don’t select the wrong box, and so that the items are picked quickly and accurately as the SKUs grow.

2. Lack Of Space For Manual Processes

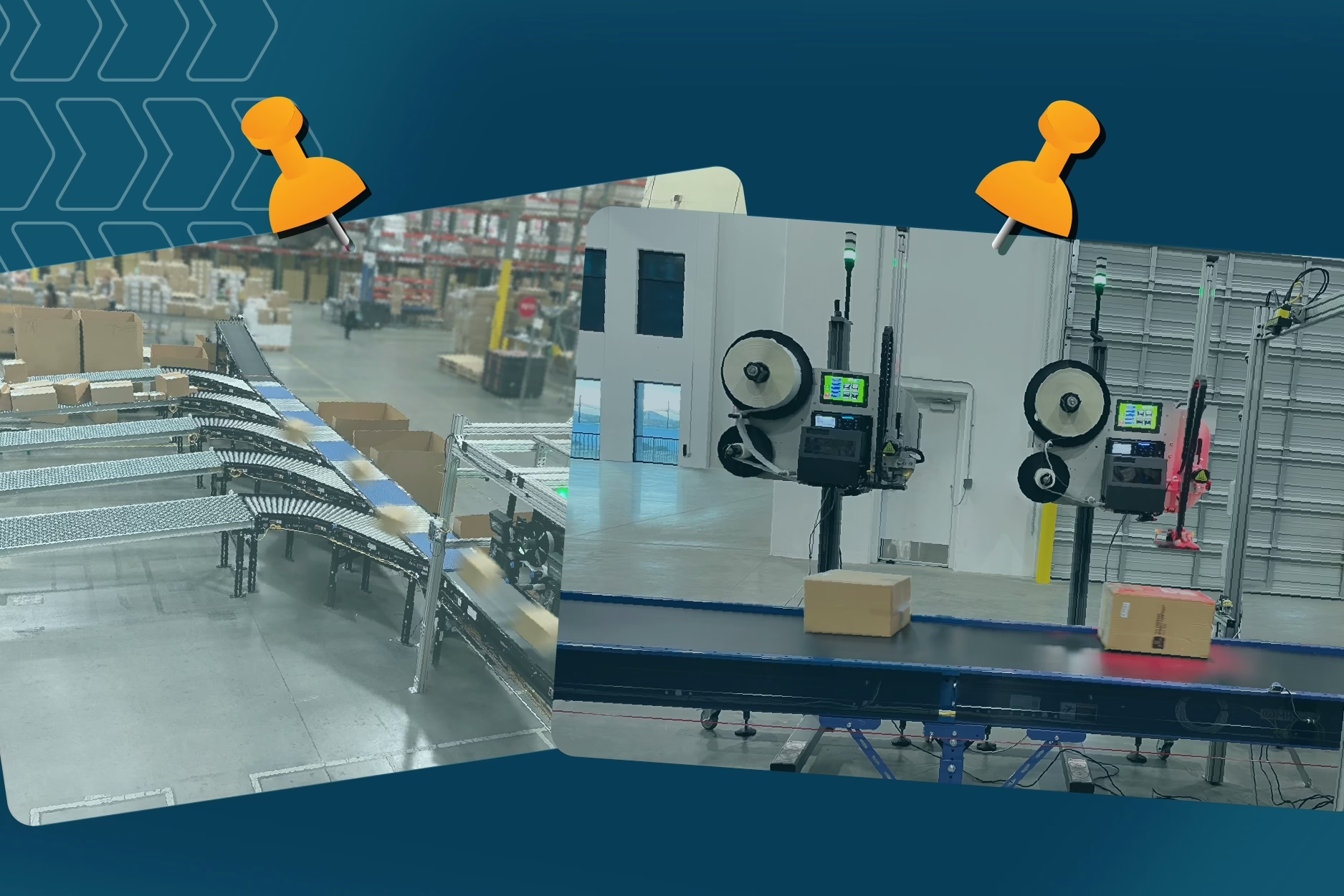

Often, we receive requests from growing warehouse operations looking to ‘add more pack tables so our team can pack orders faster during peak seasons.’ A savvy material handling applications engineer will take a step further and ask a series of follow-up questions: What tasks are your pack operators performing? If the answer includes handling box selection, taping, entering weights and dimensions, and manually printing shipping labels, there’s an opportunity for automation to take some of these tasks off their plate. Instead of simply adding more pack stations, we might suggest automating the packing process itself—such as performing the picking directly into the carton, adding in-line taping, gathering dimensions and weights, and applying the shipping label all along the conveyor in real time. By automating these tasks, we might even be able to reduce the number of pack stations needed, saving valuable space while increasing efficiency.

3. Errors Are Affecting Your Bottom Line

Even small mistakes in picking, packing, or labeling can add up and affect customer satisfaction and your bottom line. Automation significantly reduces human error, ensuring higher accuracy and fewer costly mistakes in your operations. Mistakes cost money and make customers unhappy. One of the biggest advantages of any automation is that it removes human error. Mis-keying an address, picking the wrong item, or choosing the wrong box size is greatly reduced.

4. Too Many Human Touches Per Order

When orders require multiple manual steps-sorting, labeling, packing, etc. – it can lead to inefficiencies and delays. Manual processes and operational bottlenecks increase the chances that the team won’t meet their daily or weekly fulfillment goals. Automation helps reduce the number of manual touches per order, speeding up fulfillment and ensuring that your team meets daily and weekly goals more effectively.

5. Carrier Chargebacks

Incorrect package weights, dimensions, or labeling can result in costly chargebacks from carriers. By automating the measuring and labeling process, you can ensure that packages are correctly weighed and dimensioned, helping you avoid extra fees and reducing shipping costs—and can rate shop for the best price too.

6. Running at Maximum Capacity

If your warehouse is operating at or near full capacity, it may be not easy to accommodate more orders or clients. Automation can help you optimize processes and increase efficiency, giving you the flexibility to grow and take on more business without sacrificing performance. How well would your warehouse be able to accommodate a new client? If signing on a new account is a source of anxiety rather than celebration, it’s time to look at automating. Every business needs room to grow, and if you’re already running at nearly 100%, the best option is to optimize efficiency by saying goodbye to manual operations that aren’t absolutely necessary.

Simple Automation Solutions For Big Results

Automation doesn’t have to be intimidating or overwhelming. In many cases, simple automated solutions can provide significant benefits:

- Maximizing Efficiency with End-of-Line Shipping Automation: Packaging automation that either builds a unique box sized for each order or merely forms and seals them automatically can be a huge step in the right direction. Paired with StreamTech’s conveyor, weigh, dimension, labeling, and sortation systems, this type of solution can bring a revolutionary change to the way orders are shipped. This combination not only optimizes packaging but also ensures efficient use of shipping space, reduces unnecessary packaging, and streamlines the entire process. For example, when integrated with the Sprinter, our end-of-line shipping solution, this system calculates dimensions, weight, and applies the correct shipping label at an impressive rate of 15 cartons per minute. For even greater speed, in-motion systems offer enhanced throughput, making it the #1 solution for growing fulfillment companies looking to meet increasing demands with ease.

- Boosting Accuracy and Efficiency with Pick-to-Light Technology: Pick-too-light technology enhances order fulfillment by guiding workers to the correct items with visual cues, improving speed and accuracy. Whether using StreamTech’s VelocityPick software combine with either Smart Carts or Conveyorized pick modules, or put-to-light solutions, whether you need 10 pick locations or 1000, this adaptable system can be tailored to your specific needs, reducing training time and minimizing errors. With faster, more accurate picking, your team can handle higher volumes and meet growing demand while ensuring top-notch customer satisfaction. Pick-to-light streamlines operations and supports business growth by increasing efficiency at every stage of the process.

Real-World Examples Of Automation In Action

Custom Gift Company Implements First Fulfillment Automation, Sees 60% Improvement in Labor Efficiency

Pic the Gift, specializing in personalized products like blankets and mugs, faced inefficiencies with their manual fulfillment process, especially during peak seasons. Their labor-intensive process required constant role rotation and extensive training, which impacted their ability to meet growing demand.

Solution: StreamTech’s Automated Fulfillment System

StreamTech implemented a customized automation solution to streamline Pic the Gift’s process. After printing, blankets are folded, shrink-wrapped with order tickets inside, and tracked through the system. The items are then weighed, dimensioned, and packaged automatically, with quality control checks, label verification, and sorting by carrier—all without manual intervention.

Results: Increased Efficiency And Reduced Labor Costs

In just three months, automation handled over 40% of their fulfillment tasks, significantly easing the burden on staff. During their first holiday season with automation, Pic the Gift fulfilled the same number of orders with 60% less labor, eliminating the need for 24-hour shifts and reducing worker fatigue.

Chris Cormack, Director of Operations, noted, “Automation really showed us what we’re capable of! We were able to get through peak season with the same amount of manpower, less fatigue, and without 24 hour shifts for the first time.“

Looking Ahead

As the company grows, Pic the Gift plans to expand automation to improve efficiency further. Ryan Schneider, Process Improvement Engineer, highlighted, “Being able to automate the shipping process has allowed our workers a lot less strain on their bodies. It’s a lot easier for them to do their jobs, which is really important to us. It’s all about making their day to day easy, they’re happy when they come in, when they’re happy, they pay more attention, the job gets done better. We want to continue to provide a safe workplace that allows our people to succeed, and as we continue going that way, the more automation we can get the better.”

Key Takeaways

- Automation is scalable: You do not need a complete overhaul to see results. Many small and affordable systems can deliver fast ROI and immediate efficiency gains.

- Common myths hold companies back: Automation is not always expensive, complex, or dependent on advanced IT infrastructure, and modern systems are designed for reliability and easy integration.

- Know when you are ready: Signs include growing product variety, lack of space for manual processes, frequent errors, or reaching maximum capacity.

- Simple solutions make a big impact: Technologies such as end-of-line shipping automation and pick-to-light systems can dramatically improve speed and accuracy.

- Real-world results: StreamTech clients like Pic the Gift have achieved up to sixty percent labor savings while improving employee satisfaction and eliminating overnight shifts.

- The right approach matters: Thoughtful, data-driven design ensures each automation step supports long-term growth, creating a safer, more efficient, and more scalable fulfillment process.

A Mindful Approach To Fulfillment Automation

There are rare cases where it’s smart to keep the human touch of manual processes in the warehouse. But most of the time, including automated systems will improve efficiency and enable future growth.

At StreamTech, we believe in a targeted, calculated approach to automation, rather than automating for automation’s sake. We can start by taking a look at your entire throughput process, and then find solutions that make sense for your company and goals.

Ready for Automation? If you’re looking to improve efficiency and reduce labor costs, contact StreamTech to discuss how we can tailor a solution for your business.