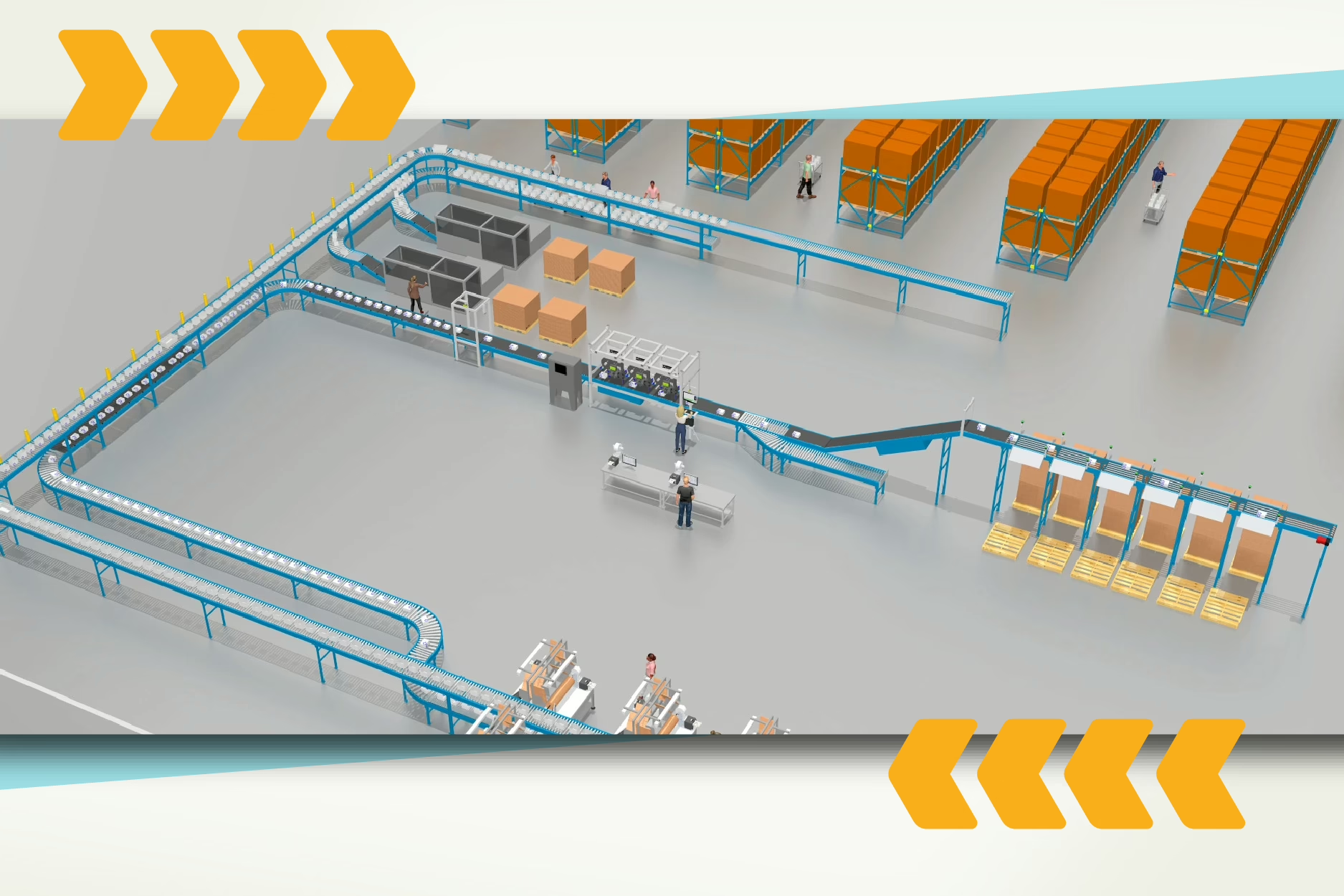

Reimagine what your warehouse can do.

Conveyors, controls and software integration.

We build the systems, controls and software to automate fulfillment.

As a material handling systems integrator, we design and implement automation that keeps your warehouse running fast, accurate, and efficient. From picking to shipping, our solutions help you move smarter, cut costs, and deliver on time—every time.

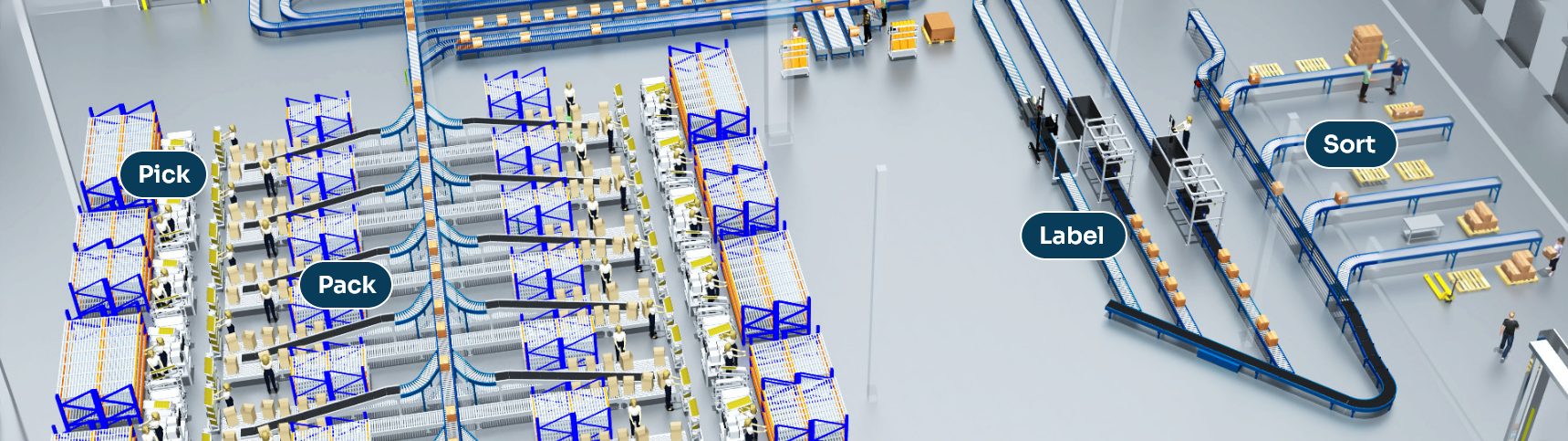

Our technologies make order fulfillment faster, more accurate and efficient.

From the first scan to the final sort, our engineering systems handle the heavy lifting—automating what used to be manual, error-prone, and time-consuming. Whether it’s everyday orders or all-out peaks, our solutions adapt, learn, and optimize on the fly—so your warehouse keeps running smarter, faster, and with fewer hands.

Ready to speak to our solutions team?

What Are Your Warehouse Fulfillment Goals?

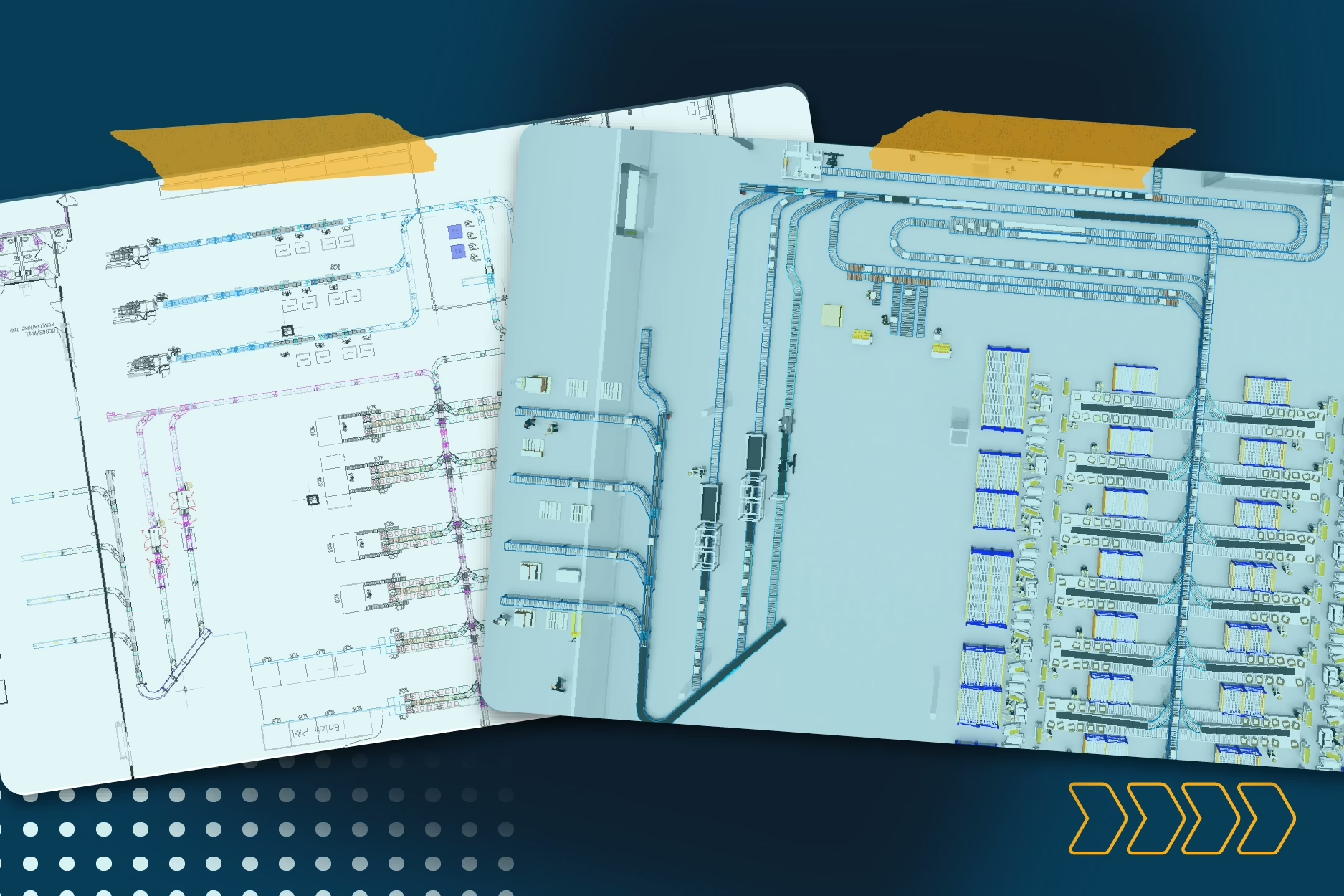

Our mission is to help you reach the fulfillment goals that matter most to your business. We analyze your operation, model potential outcomes, and deliver systems built to align with your priorities—so every improvement directly supports your path to growth.

See How DCL Logistics Uses Automation

During promotions, product launches, and peak demand, DCL’s order volume can double or triple. Adapting to these fluctuations is crucial for maintaining the high service levels clients expect. By leveraging automation, DCL scales seamlessly to ensure accurate, on-time, and cost-effective fulfillment—driving customer satisfaction.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields