Pick-To-Light Picking System

Streamline Order Picking with Intelligent Light Technology

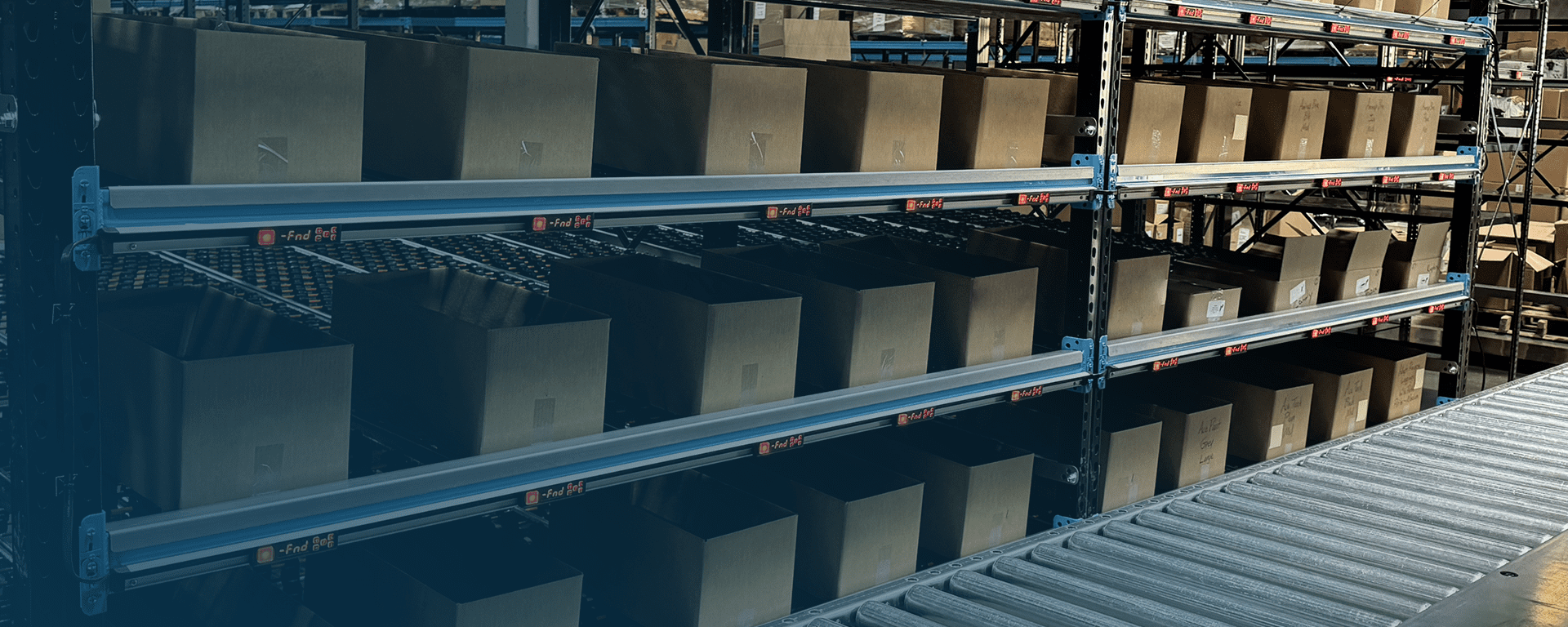

Our VelocityPick™ pick-to-light picking system is designed to streamline the order fulfillment process by using light-directed technology to guide pickers to the exact location of the needed items. This system reduces dependency on manual processes, increases accuracy, and speeds up picking times, making it an essential solution for high-volume warehouses.

With its intuitive design and integration with warehouse management systems, VelocityPick™ ensures real-time updates and optimizes workflow efficiency. By minimizing errors and reducing labor costs, this system boosts productivity and enhances overall order fulfillment speed, helping businesses meet the demands of today’s competitive logistics landscape.

Pick-To-Light Picking System - How It Works

In this picking system, the process is designed as a zone pick mod, also referred to as “pick and pass.” The VelocityPick™ software is actually managing a basic cartonization process, so that the carton is sized to each order.

- Once the orders are sent to the VelocityPick™ software, cartons are built to size, and placed along the conveyor with an LPN

- When the order arrives to the operator’s Zone, if there’s a pick necessary for them, the conveyor lights up, and the box stops at their zone

- The operator scans the box, and the rack lights up with the necessary items, and quantities. The operator picks the items, pressing the “confirm” button each time.

- Once the items are picked, the operator can move that box into the takeaway area, and move on to the next box.

- Each order will convey through the appropriate pick mods until completely picked

- From there, it can proceed to be sealed, then dimensioned, weighed, labeled and sorted

Pick-To-Light Picking System - How It Works

In this picking system, the process is designed as a zone pick mod, also referred to as “pick and pass.” The VelocityPick™ software is actually managing a basic cartonization process, so that the carton is sized to each order.

- Once the orders are sent to the VelocityPick™ software, cartons are built to size, and placed along the conveyor with an LPN

- When the order arrives to the operator’s Zone, if there’s a pick necessary for them, the conveyor lights up, and the box stops at their zone

- The operator scans the box, and the rack lights up with the necessary items, and quantities. The operator picks the items, pressing the “confirm” button each time.

- Once the items are picked, the operator can move that box into the takeaway area, and move on to the next box.

- Each order will convey through the appropriate pick mods until completely picked

- From there, it can proceed to be sealed, then dimensioned, weighed, labeled and sorted

VelocityPick™ Smart Carts

Pick, Move, and Fulfill with Light-Guided Smart Carts

Pickers can batch pick multiple orders simultaneously using a pick-to-light equipped smart cart. The cart will be filled with empty cartons, each representing an order with its own ID.

The picker travels with that cart along either SKU-dense rack of common “high movers” until all orders are fulfilled, or the cart may travel to the next “pick zone” where another worker takes the cart, until all orders are fulfilled. The rack can be active with lights, or passive with another marker such as a SKU or bin location.

VelocityPick™ Smart Carts

Pick, Move, and Fulfill with Light-Guided Smart Carts

Pickers can batch pick multiple orders simultaneously using a pick-to-light equipped smart cart. The cart will be filled with empty cartons, each representing an order with its own ID.

The picker travels with that cart along either SKU-dense rack of common “high movers” until all orders are fulfilled, or the cart may travel to the next “pick zone” where another worker takes the cart, until all orders are fulfilled. The rack can be active with lights, or passive with another marker such as a SKU or bin location.

Features & Benefits of Smart Carts

Discover How Our Smart Cart Technology Transforms Warehouse Order Fulfillment

Increase Pick Rate, Speed & Accuracy

Adding carts can increase the number of orders one picker can fulfill. The addition of the automated lights takes the guesswork out of the process, speeding up each pick.

Real-Time Inventory Integration

Real-time visibility into stock levels and movement enables better inventory control, demand forecasting, and replenishment planning, ultimately reducing stockouts, overstock situations, and associated costs.

Easy to Implement & Scale

Pick carts allow you to automate your existing pickers, and then add more carts as your business grows, or to accommodate peak seasons or new product lines.

Customizable Carts

Carts can be designed to meet your specifications, to maximize cartons and pick locations on each rack. Or your existing carts can be easily retrofitted with the magnetic, battery-operated light devices.

Wireless Devices

The FCC-approved devices connect wirelessly via router base station, and use e-paper displays to conserve battery. The three side buttons and large multi-colored confirm button allow operators to perform functions such as replenishment and short picks directly from the device, through StreamTech's picking software. With seven colors, many operators can work in the same area.

VelocityPick™ Zone Pick Mods

Light-Driven Zone Picking for Maximum Productivity

Each inventory bin location is equipped with a light module, usually along a consolidated inventory aisle, called a “forward pick rack”. Empty cartons convey to the pick-to-light area with their own unique ID barcode.

Once the carton is inducted, the system directs the picker to the location of the items by illuminating the corresponding lights. As each item is picked, the worker confirms the pick by pressing a button or triggering a sensor. Completed order cartons can advance once all items are picked.

VelocityPick™ Zone Pick Mods

Light-Driven Zone Picking for Maximum Productivity

Each inventory bin location is equipped with a light module, usually along a consolidated inventory aisle, called a “forward pick rack”. Empty cartons convey to the pick-to-light area with their own unique ID barcode.

Once the carton is inducted, the system directs the picker to the location of the items by illuminating the corresponding lights. As each item is picked, the worker confirms the pick by pressing a button or triggering a sensor. Completed order cartons can advance once all items are picked.

Features & Benefits of Zone Pick Mods

Automate and Simplify Picking with Light-Equipped Zones

Improved Efficiency & Throughput

Pick modules are designed to optimize the picking process by organizing inventory in a systematic manner, resulting in faster order fulfillment and increased throughput as orders convey through the pick zone.

Scalability & Flexibility

Pick modules can be designed and configured to adapt to changing business needs and inventory profiles. Whether accommodating seasonal fluctuations, new product lines, or shifts in demand patterns, pick modules offer scalability and flexibility to support evolving warehouse operations.

Real-Time Inventory Integration

Real-time visibility into stock levels and movement enables better inventory control, demand forecasting, and replenishment planning, ultimately reducing stockouts, overstock situations, and associated costs.

Reduced Errors

With a structured layout and clear labeling systems, pick modules minimize the likelihood of picking errors. Pick modules help to prevent mistakes such as picking the wrong item or quantity, ultimately enhancing accuracy and customer satisfaction.

Wired Devices

The wired devices are well suited for applications with a high volume of pick locations across many SKUs. The devices are mounted on a piercing cable contact for easy installation. Devices have a multi-colored pick confirm button to allow multiple operators to work in the same area, and five function keys that correspond to StreamTech's picking software.

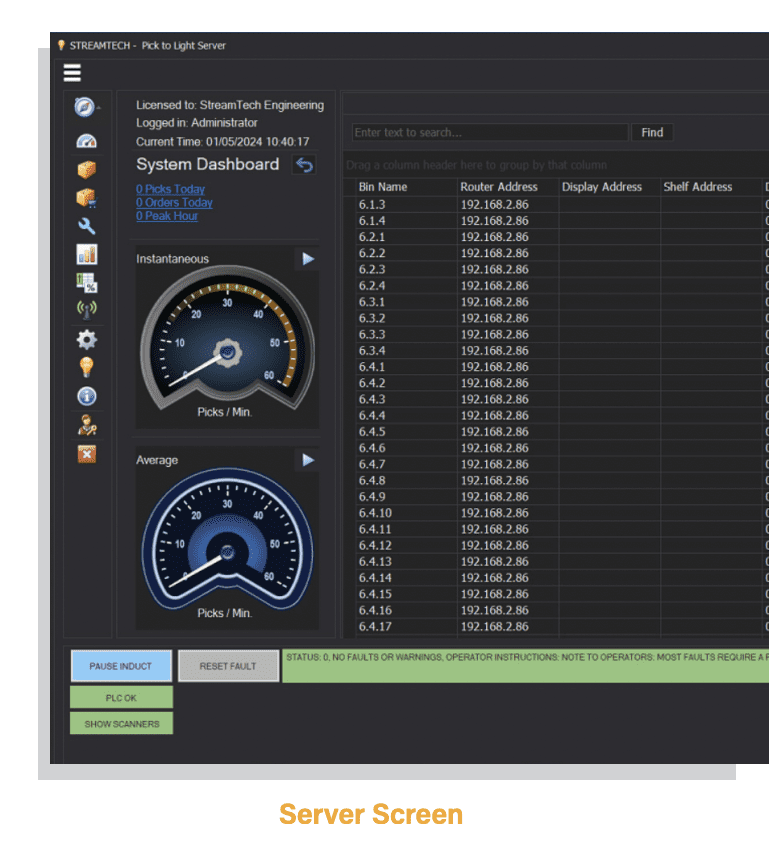

Server-Side Picking Software

StreamTech’s WCS Picking software interfaces with your WMS, and allows you to manage all the Picking Client stations, and gives you additional administrative functions such as:

- Manage operators’ accounts and log-ins

- Order import – wave and order management

- SKU management – importing from item master

- Bin/SKU mapping

- PTL device management – add/remove, monitor faults for PTL equipment

- Conveyor pick zone path routing

- See SKU quantities, lot numbers, picks per station

- See picks per minute

- Read and export weekly reports showing picking totals, averages, scanner health and pick accuracy %

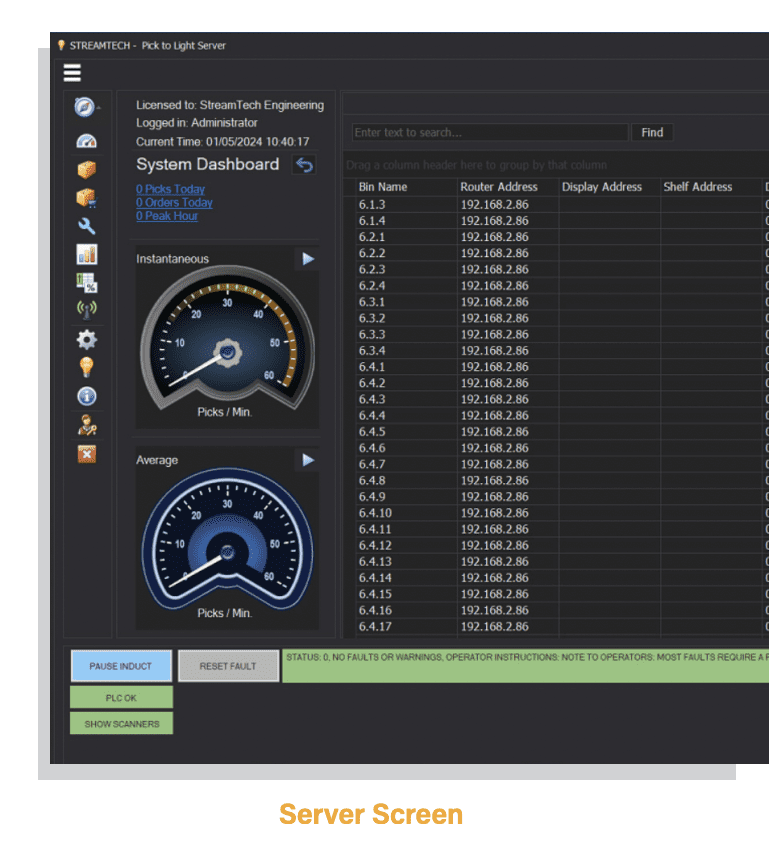

Server-Side Picking Software

StreamTech’s WCS Picking software interfaces with your WMS, and allows you to manage all the Picking Client stations, and gives you additional administrative functions such as:

- Manage operators’ accounts and log-ins

- Order import – wave and order management

- SKU management – importing from item master

- Bin/SKU mapping

- PTL device management – add/remove, monitor faults for PTL equipment

- Conveyor pick zone path routing

- See SKU quantities, lot numbers, picks per station

- See picks per minute

- Read and export weekly reports showing picking totals, averages, scanner health and pick accuracy %

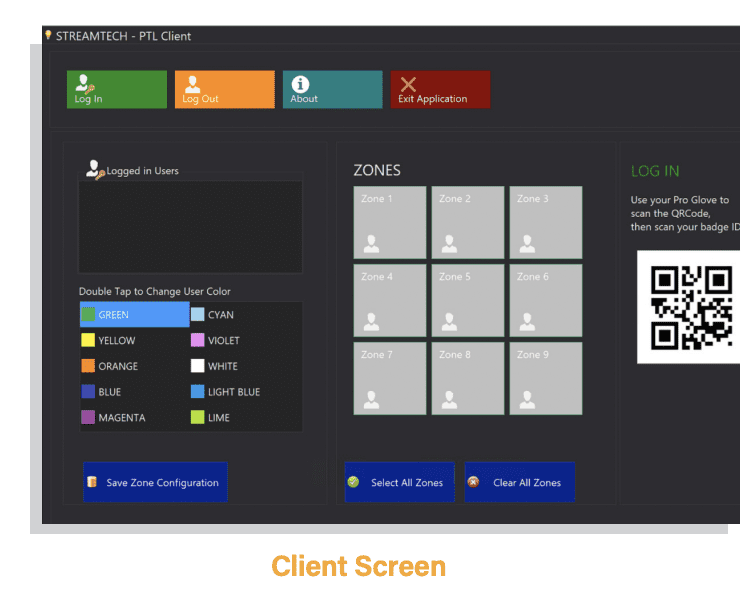

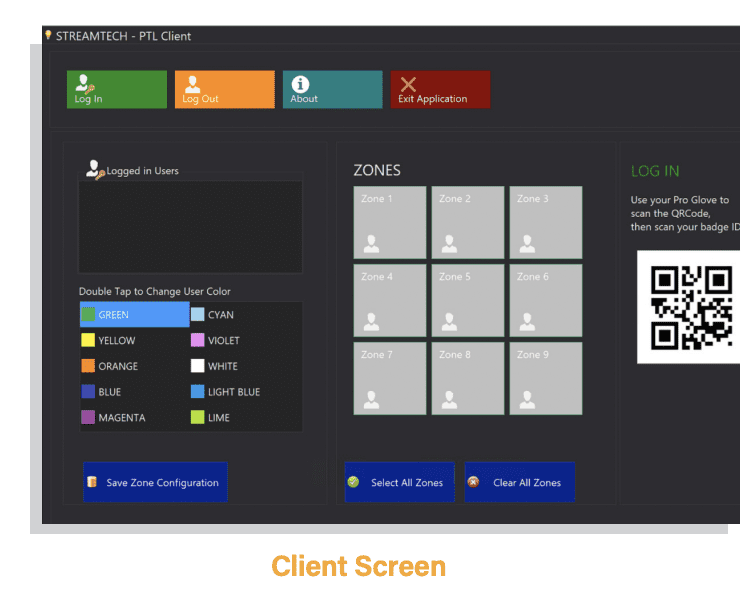

Client-Side Picking Software

On the client devices, picker operators can sign-in, and assign themselves to one or many pick zones. There is a client station at each zone for convenience.

- Sign-in by operator badge ID (tracks performance)

- Choose operator pick light colors

- Divide operators into full zones or split zones to up to 3 operators (called areas)

- Managers can use any client device to see the operator coverage of the whole system

Client-Side Picking Software

On the client devices, picker operators can sign-in, and assign themselves to one or many pick zones. There is a client station at each zone for convenience.

- Sign-in by operator badge ID (tracks performance)

- Choose operator pick light colors

- Divide operators into full zones or split zones to up to 3 operators (called areas)

- Managers can use any client device to see the operator coverage of the whole system