Solving E-Commerce Order Fulfillment Challenges with Sortation:

StreamTech Engineering has extensive experience in implementing complex sortation automation installations for a wide variety of clients. Utilizing a combination of both our sortation hardware, and the StreamTech WCS software, we can provide very cost-effective, user-configurable sortation systems for a wide variety of applications.

Choosing the Right Sortation Technology Involves a Few Factors

There are a variety of design considerations necessary to take into account, in order to determine which sortation technology is best suited to the job. Read through them below and reach out to our team.

Package Profile

Boxes, polybags, flats…

The types of packages make a big impact in the correct sort technology. There are certain sorters which are best suited for boxes, while others work well for bags, padded mailers, flat envelopes, or loose garments. There is no “one size fits all” sorter.

Size & Weight

Long, heavy or light items…

Understanding the length and width of each package will determine how large each sort location or lane needs to be, and how well each item will transfer. Weight data is important to specify the correct technology, for both conveyability and weight limits.

Sort Data

What info will we sort on?

Is the sortation data in the LPN barcode? If sorting by carrier, some customers choose to scan the shipping label after it has been applied. In other cases, sort data could be determined by dimensions, sorting by large/small or by package type.

Throughput

How fast should we target?

Throughput is often the data point customers focus on first. How many packages will need to be sorted in a given timeframe? Typically we measure daily or hourly package throughput. Each sorter technology has a maximum rate, so we’ll ensure your system is designed to meet your goal, using the appropriate technology.

Locations

How many sort locations?

The number of locations will typically be the data point used to determine how many individual sorters are necessary. For many technologies, one sorter can divert to two locations. There are some technologies that allow multiple locations on one belt.

Destination

Gaylords, docks, or trucks?

The type of destination will have an impact on how the system is designed. If sorting to gaylords or mail carts, it’s important to understand the volume of the bin, the throughput, and how fragile your items are. Items could also be sorted into a variety of lanes leading to dock doors.

Successful Sortation Requires A Combination of Robust Controls & Intelligent Software

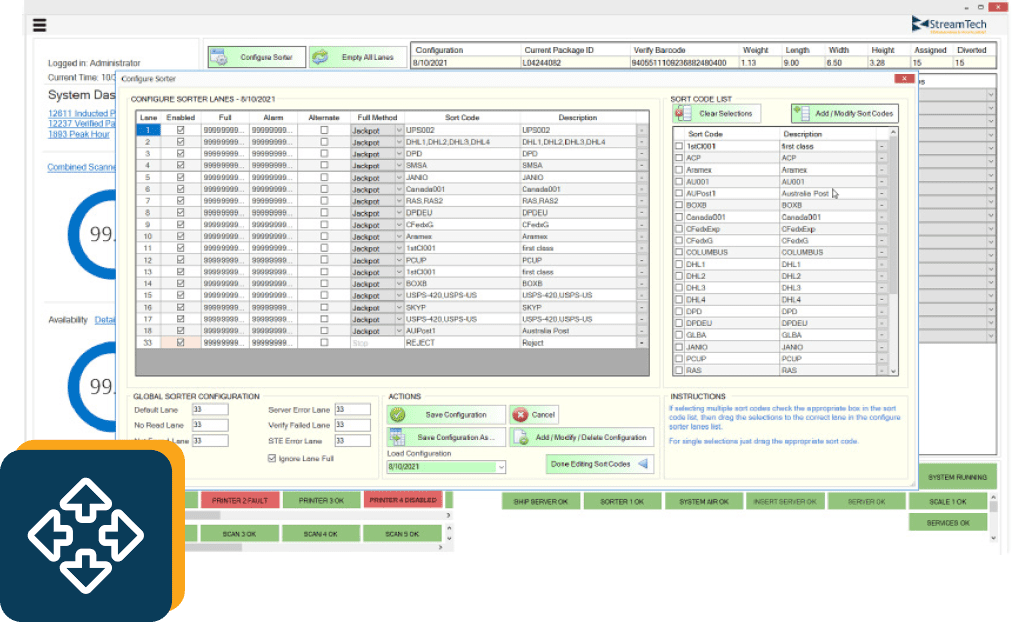

Powerful WCS Sortation Software

In addition to monitoring exceptions, faults and verification in the WCS, StreamTech’s Sortation module allows customers to define their own Sort Codes, and assign them to each lane, using a drag-and-drop configuration. This allows ultimate flexibility to change and re-define the lanes as needed.

Users can also define and save “recipes.” If there are a few different sort lane configurations that are used often – maybe during different times of the year – they can save them and easily switch all lanes at once.

The Sortation software also monitors lane full conditions, allowing either overflow to another lane, or a pause of the sorter altogether.

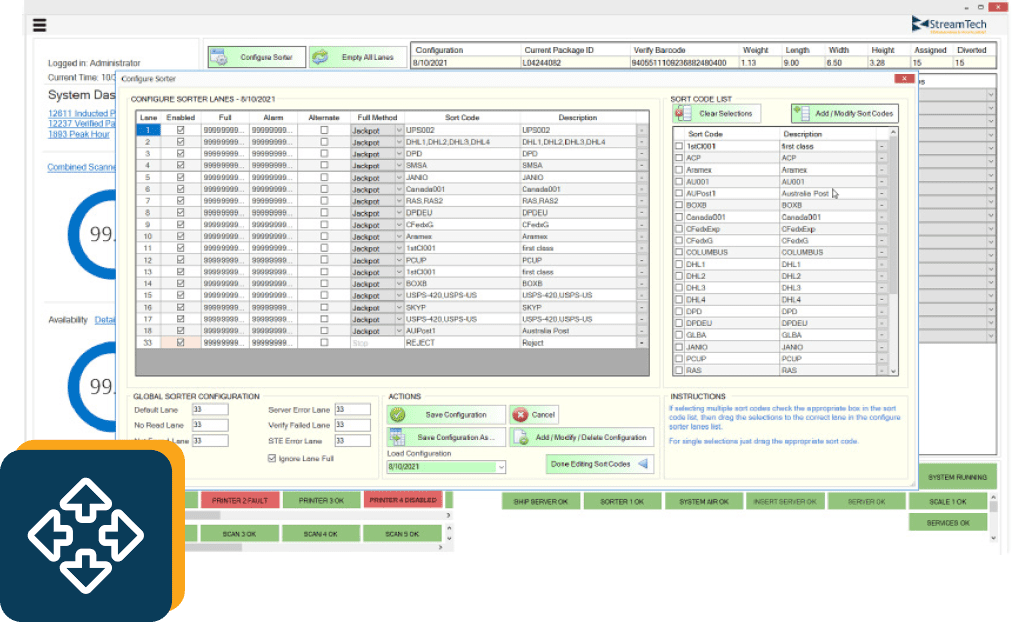

Powerful WCS Sortation Software

In addition to monitoring exceptions, faults and verification in the WCS, StreamTech’s Sortation module allows customers to define their own Sort Codes, and assign them to each lane, using a drag-and-drop configuration. This allows ultimate flexibility to change and re-define the lanes as needed.

Users can also define and save “recipes.” If there are a few different sort lane configurations that are used often – maybe during different times of the year – they can save them and easily switch all lanes at once.

The Sortation software also monitors lane full conditions, allowing either overflow to another lane, or a pause of the sorter altogether.

Robust Controls Hardware

Machine control is provided by an Allen Bradley CompactLogix PLC, which is easily expandable to manage additional automation. Its open architecture means that end users are able to support themselves if desired.

- Add diverters, merges, etc.

- Open, standard PLC architecture

- All devices IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low cost system control of reseller conveyor equipment

- EWON remote support router included (eliminates need to go through VPN)

Robust Controls Hardware

Machine control is provided by an Allen Bradley CompactLogix PLC, which is easily expandable to manage additional automation. Its open architecture means that end users are able to support themselves if desired.

- Add diverters, merges, etc.

- Open, standard PLC architecture

- All devices IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low cost system control of reseller conveyor equipment

- EWON remote support router included (eliminates need to go through VPN)

Some of Our Sortation Technologies:

ModSort®

Omni-Directional Sortation

Modsort provides an all-electric solution to handling a wide variety of form factors, in a compact footprint.

- Motorized Drive Rollers (MDR) and controls that employ run-on-demand technology

- 24-volt DC motor and controls that allow flexibility in wiring and control

- The ability to divert exceptionally small packages and boxes

- No pneumatics, lifts, or Z-direction position feedback devices are needed

- Safe, energy-efficient, quiet, and low-maintenance operation

ModSort®

Omni-Directional Sortation

Modsort provides an all-electric solution to handling a wide variety of form factors, in a compact footprint.

- Motorized Drive Rollers (MDR) and controls that employ run-on-demand technology

- 24-volt DC motor and controls that allow flexibility in wiring and control

- The ability to divert exceptionally small packages and boxes

- No pneumatics, lifts, or Z-direction position feedback devices are needed

- Safe, energy-efficient, quiet, and low-maintenance operation

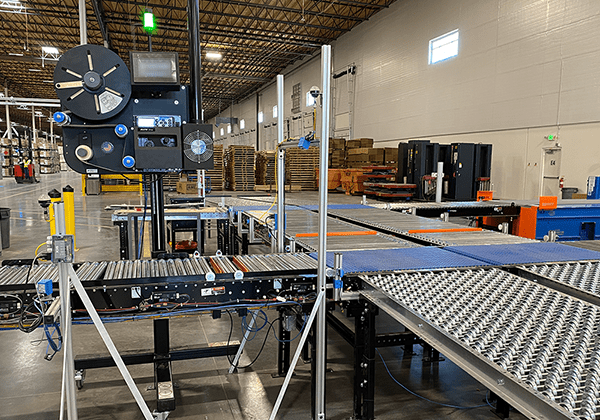

Urethane Belt Transfer

Single Or Bi-Directional Sortation

Transfers are used to merge and/or divert products onto and from roller conveyors, especially MDR and lineshaft conveyors. Pick Zone Modules (PZM) are a special high-speed adaptation of transfers offering speeds up to 30-40 cases per minute. Transfers are typically accomplished on urethane belts or wheels and can be at a shallow angle or a full right-angle 90 degrees. Transfers are engineered to prevent “rolling off” of the belts at higher speeds. For MDR transfers, the drive cards are all pre-mounted, allowing for ease of installation and control.

- Bi-Directional Transfers available

- Design protects urethane bands from “rolling”

- Side wings on PZM have wheels for fast transfer

- Pre-wired and plumbed for easy installation

- Induction conveyors available

- Integrates with Lineshaft and IntelliROL product lines

Urethane Belt Transfer

Single Or Bi-Directional Sortation

Transfers are used to merge and/or divert products onto and from roller conveyors, especially MDR and lineshaft conveyors. Pick Zone Modules (PZM) are a special high-speed adaptation of transfers offering speeds up to 30-40 cases per minute. Transfers are typically accomplished on urethane belts or wheels and can be at a shallow angle or a full right-angle 90 degrees. Transfers are engineered to prevent “rolling off” of the belts at higher speeds. For MDR transfers, the drive cards are all pre-mounted, allowing for ease of installation and control.

- Bi-Directional Transfers available

- Design protects urethane bands from “rolling”

- Side wings on PZM have wheels for fast transfer

- Pre-wired and plumbed for easy installation

- Induction conveyors available

- Integrates with Lineshaft and IntelliROL product lines

PolySort

Bi-Directional Sortation of Polybags and "Non-Sortables"

The NBS90 PolySort delivers great value for the sortation of mixed polybag and carton handling. Design enhancements prevent polybags from sagging between the belts while high-friction natural rubber transfer rollers provide maximum grab on slippery polybags. Individual, automatic, pneumatic, belt take-ups provide even belt tension on each individual belt and extra high and low transfer lifts with guides to keep polybags from snagging.

Capable of belt speeds up to 300 feet per minute and can be used with an extreme range of mixed poly and Jiffy envelopes, and products, including small parcels and packages from 2 ounces to 40 pounds.

- Up to 50 CPM

- Polybags, flats, envelopes, and cartons

- Speeds up to 300 fpm

- Minimum product size from 4″ x 4″ x 2oz.

- Maximum product size up to 24″ x 28″ x 40 lbs

PolySort

Bi-Directional Sortation of Polybags and "Non-Sortables"

The NBS90 PolySort delivers great value for the sortation of mixed polybag and carton handling. Design enhancements prevent polybags from sagging between the belts while high-friction natural rubber transfer rollers provide maximum grab on slippery polybags. Individual, automatic, pneumatic, belt take-ups provide even belt tension on each individual belt and extra high and low transfer lifts with guides to keep polybags from snagging.

Capable of belt speeds up to 300 feet per minute and can be used with an extreme range of mixed poly and Jiffy envelopes, and products, including small parcels and packages from 2 ounces to 40 pounds.

- Up to 50 CPM

- Polybags, flats, envelopes, and cartons

- Speeds up to 300 fpm

- Minimum product size from 4″ x 4″ x 2oz.

- Maximum product size up to 24″ x 28″ x 40 lbs

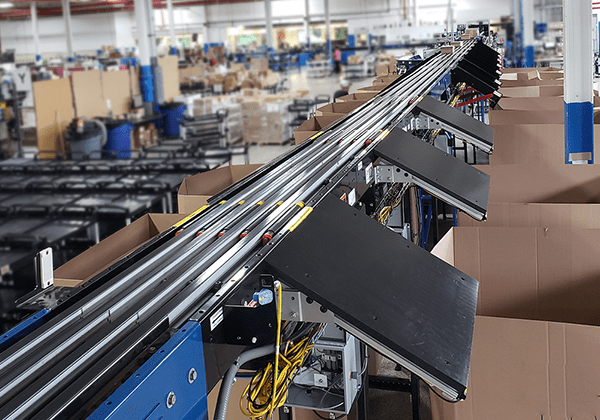

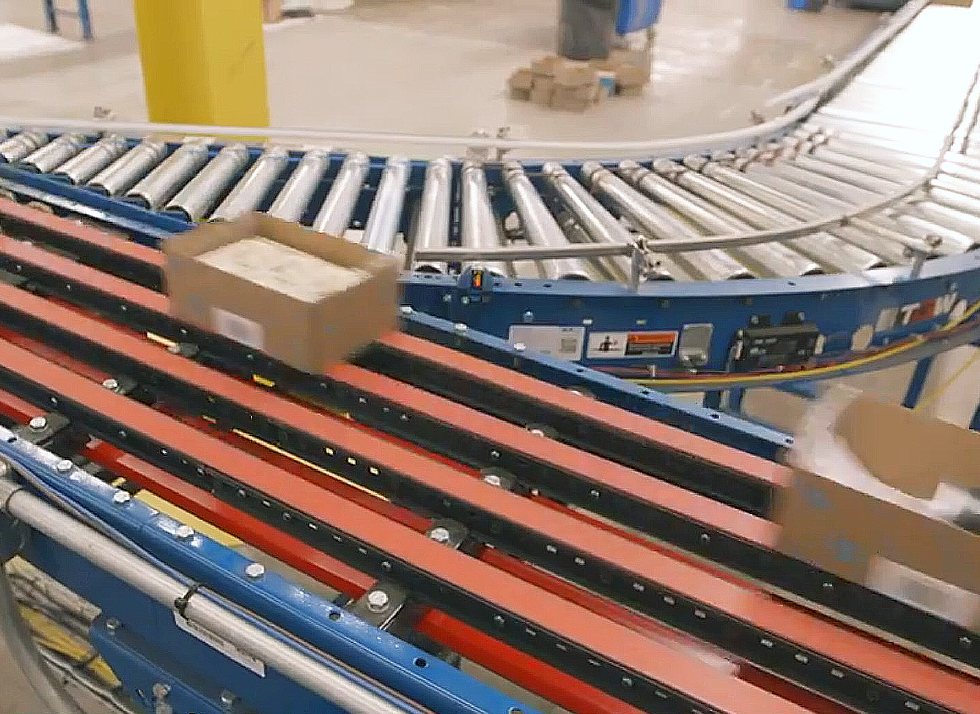

Narrow Belt

30° Single or 90° Bi-Directional Sortation

TGW invented and patented the Narrow Belt sorter and today’s improvements help keep it above and beyond competitive models. Products on the moving belt have zero relative motion, enhancing accuracy. Each carrying belt has its takeup, to provide for long life and low maintenance. Both right-angle and oblique-style diverts are available, as shown below on a test conveyor. An open design allows for debris to fall through, enhancing cleanliness. Much lower noise and maintenance requirements than for sliding-shoe style sorters.

For very high-speed applications, the patented “Wave” technology (available at a reasonable price) allows for dynamic gapping between products and as a result, much higher throughputs, even at moderate speeds. Small-item versions are especially attractive for e-commerce applications.

- Up to 65 CPM (NBS90) 100 CPM (NBS30), 170 CPM (NBS30-Wave)

- Small item version available, NBS90SP down to 4″ x 4″ product

- Speeds up to 450 fpm

- Maximum lengths up to 200 ft.

- Maximum product size up to 75 lb.

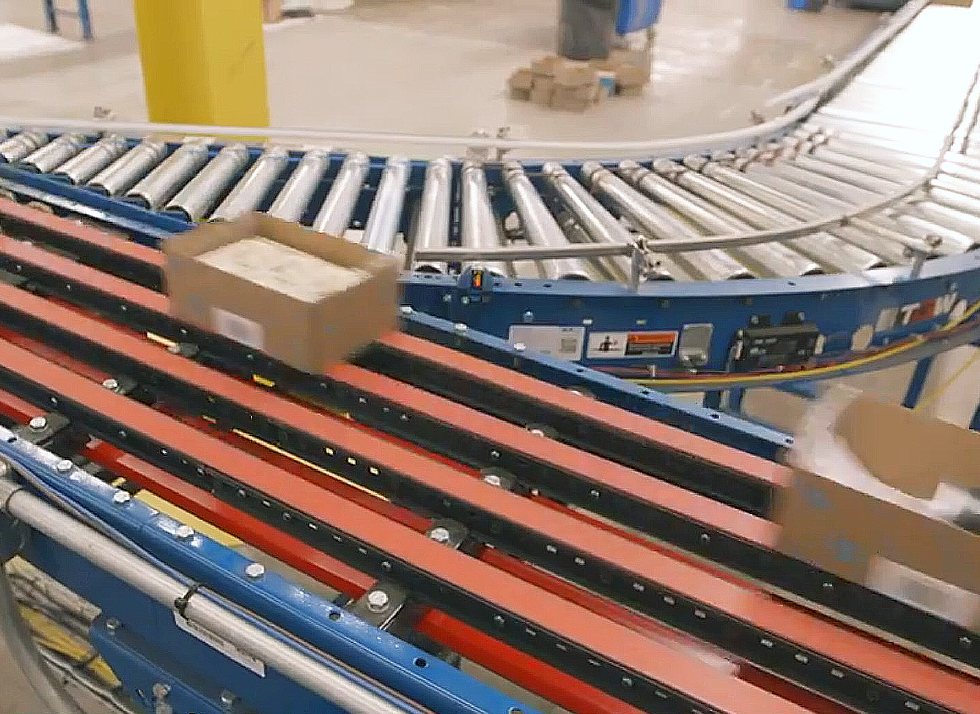

Narrow Belt

30° Single or 90° Bi-Directional Sortation

TGW invented and patented the Narrow Belt sorter and today’s improvements help keep it above and beyond competitive models. Products on the moving belt have zero relative motion, enhancing accuracy. Each carrying belt has its takeup, to provide for long life and low maintenance. Both right-angle and oblique-style diverts are available, as shown below on a test conveyor. An open design allows for debris to fall through, enhancing cleanliness. Much lower noise and maintenance requirements than for sliding-shoe style sorters.

For very high-speed applications, the patented “Wave” technology (available at a reasonable price) allows for dynamic gapping between products and as a result, much higher throughputs, even at moderate speeds. Small-item versions are especially attractive for e-commerce applications.

- Up to 65 CPM (NBS90) 100 CPM (NBS30), 170 CPM (NBS30-Wave)

- Small item version available, NBS90SP down to 4″ x 4″ product

- Speeds up to 450 fpm

- Maximum lengths up to 200 ft.

- Maximum product size up to 75 lb.

Custom Sortation

Other Sortation Options

Sortation does not have to be complicated. There are a wide variety of ways to handle the sortation of your packages. It all depends upon the type of item, how specific the alignment needs to be, and why it’s being redirected.

StreamTech can even offer home-grown sortation solutions if the application is right.

Custom Sortation

Other Sortation Options

Sortation does not have to be complicated. There are a wide variety of ways to handle the sortation of your packages. It all depends upon the type of item, how specific the alignment needs to be, and why it’s being redirected.

StreamTech can even offer home-grown sortation solutions if the application is right.

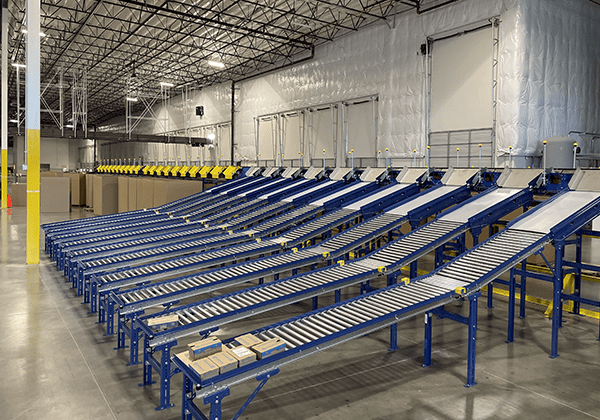

Experts in Conveyance

MHS Conveyor Integrator

StreamTech Engineering has extensive experience implementing complex conveyor installations for a wide variety of clients. Utilizing MHS’s high performance conveyor systems gives us the ability to provide a family of conveyor styles to suit your unique application, with maintenance-saving features and long support life, at a reasonable cost.

Experts in Conveyance

MHS Conveyor Integrator

StreamTech Engineering has extensive experience implementing complex conveyor installations for a wide variety of clients. Utilizing MHS’s high performance conveyor systems gives us the ability to provide a family of conveyor styles to suit your unique application, with maintenance-saving features and long support life, at a reasonable cost.