Estimated reading time: 7 minutes

The on-demand expectations of customers are increasing every day, and fulfillment warehouse operators feel this pressure more than anyone. So, when it’s time to update your systems, it can be tempting to “just get a quote” and move your project forward. But good material handling design requires time and careful planning. There really are no “instant solutions.”

To implement the most impactful fulfillment automation technology for your operation, a vendor first needs to establish a basic understanding of your business, and a detailed understanding of how orders flow through your warehouse, in a step-by-step fashion. It necessitates asking the right questions and uncovering hidden challenges. Vendors who skip these steps and jump straight to pricing often leave critical details unaddressed, leading to unnecessary change orders, unexpected expenses, and operational headaches – and often can experience huge financial losses to their business as a result.

At StreamTech, we opt for a more thoughtful intake approach that sets everyone up for smoother implementation and better long-term success.

The Value of Thorough Application Engineering Before the Proposal

In the same way highways and freeways are meticulously designed to get us from point A to point B, road development plans are not approved before and extremely thorough assessment process. The same is true for fulfillment automation: The path from raw goods to the end customer depends on a system designed to move items efficiently, but building that system requires careful consideration.

Material handling is inherently complex. It involves many variables, from the size and weight of packages to the layout of the facility, the volume of orders, the data exchange within the software stack, among others. By taking the time to collect comprehensive data upfront, automation technology vendors can design systems that align perfectly with your operation’s needs. This ensures not only a smoother implementation process but also better long-term outcomes. Vendors who don’t ask the right questions upfront and jump straight to pricing often wind up with unnecessary change orders and expenses, leaving customers to deal with the fallout.

Questions Every Warehouse Automation Systems Vendor Should Be Asking

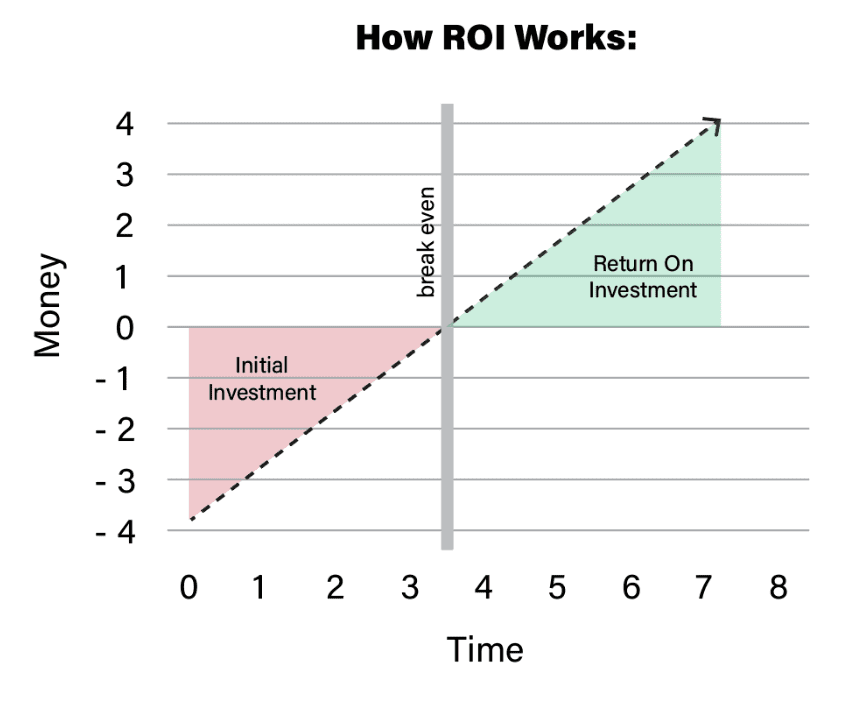

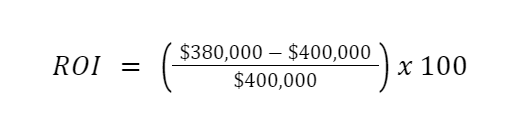

When evaluating warehouse automation systems and comparing proposals from different vendors, it’s important to know that you’re comparing apples to apples. At first glance, one proposal might appear less expensive than another…but a closer look often reveals gaps in the information collected by the vendor. If the vendor hasn’t taken the time to understand your operation in detail, their proposal may be missing key components. While this might make their pricing look attractive upfront, those gaps will likely lead to expensive change orders later when unforeseen needs arise during the implementation process.

Some of the items that vendors may not include in their proposal may shock you: installation, commissioning, on-site training, even controls and software, support and warranty, to name a few.

The vendors asking the right questions aren’t just providing accurate pricing; they’re laying the groundwork for a solution that will perform reliably and efficiently from day one. Here are some of the essential questions every vendor should be asking to design a system that works for your unique operation:

- What are your smallest and largest box sizes?

- Do you handle boxes, bags, flats, padded mailers, or a combination?

- What is your average daily volume, and how does that fluctuate during peak seasons?

- How long is your workday, and does your operation run in shifts?

- What’s the difference between a typical day and a peak-volume day?

- How many pack stations are currently in use?

- Where are your LPN barcodes located—left, right, top, bottom, or multiple sides?

- Are any items unusually long, heavy, or difficult to handle?

- Are flat items being handled, and do photoeyes need to be positioned differently to detect them?

- What type of WCS (warehouse control system) connection will be required?

- How long does it take to pick an order, and how many people are involved?

- How many lines are typically in each order?

- How many SKUs are in your inventory, and what percentage are high movers?

These final few questions are just as vital to system design. Knowing your pick rates helps right-size equipment and avoid bottlenecks or overspending. Your average lines per order determines the complexity of picking logic and cartonization. Understanding your SKU mix and fast movers ensures the system can prioritize efficiency, especially during peak demand. And your WCS requirements impact everything from scan logic to labeling to system visibility—miss this step and even the best equipment won’t deliver.

The Cost of Cutting Corners in Application Engineering Prep Work

Rushing through the initial design process or missing critical details can lead to major consequences, both operational and financial. Some examples:

Oddballs and Outliers. Let’s start with the matter of outlier items. A system designed to handle 90% of your orders efficiently may struggle with the remaining 10% if those items are unusually large, heavy, or oddly shaped. Addressing these exceptions requires a thoughtful approach—one that balances the need for efficiency with the flexibility to manage unique challenges. Skipping this step can lead to a system that’s either overengineered and inefficient or underprepared and prone to failure.

Barcode Placement. Barcode placement is another common area where oversights occur. Imagine receiving a system designed to read barcodes on one side of a box, only to find out during installation that your boxes have barcodes on multiple sides. Suddenly, you’re faced with the need for additional scanners and the associated expenses. These types of surprises can disrupt timelines, inflate budgets, and create headaches for all stakeholders.

Good Material Handling Practices. Even seemingly minor details, like the gapping of items on a conveyor, can become significant challenges. When items are placed too close together, it can interfere with essential processes like weighing, dimensioning, or labeling. To address this, systems must include conveyors that create gaps between items, a step that requires careful planning and precise engineering. Without this consideration, the entire system’s efficiency can be compromised, leading to delays and reduced throughput.

Product Packaging Profile. Finally, product packaging can also present challenges that are easy to overlook. Bagged items, for example, can be difficult to convey, label, or sort due to their irregular shapes. Whether it’s a basketball in a polybag rolling unpredictably or a pill bottle shifting within its packaging, these issues must be addressed during the design phase. Failure to do so can result in jams, labeling errors, or damaged products.

Real Results: When SteamTech’s Process Pays Off

At SteamTech, the upfront work we do is what sets our solutions apart. By taking the time to ask the right questions and understand the intricacies of your operation before finalizing your proposal, we can better ensure that your system is designed to meet your needs today and adapt to your challenges tomorrow, all while staying within budget and on schedule. After all, the success of any material handling system depends on the foundation laid during the design phase. Take these StreamTech client success stories for example:

- World Wide Technology: To improve their outbound shipping process for high-value electronics, we delivered a SLAM system that accommodates a wide range of package sizes and labels while reducing errors.

- DCL Logistics: For this 3PL, we created an adaptive system capable of scaling during peak demand periods, enhancing their ability to support high-growth eCommerce brands.

How We Turn Discovery Into a Deliverable You Can Trust

When it’s time to start the conversation, remember we aren’t just pricing machines. We’re designing processes tailored to your business. This takes time. Depending on complexity, our sales and application engineering process may take weeks or months and involves:

- Initial calls or virtual meetings to gather information.

- Requests for photos, videos, and layout drawings.

- Iterative virtual meetings to refine the concept.

- Site visits to finalize details.

- Delivery of a fully engineered proposal.

Our thorough process ensures that when your system is installed, it works seamlessly. And if adjustments are needed, we take responsibility for making it right. By contrast, rushing this process can lead to unexpected challenges that may be difficult or costly to resolve later. Taking the time upfront allows us to deliver a solution you can trust, minimizing risk and setting your business up for success.

Hoping to get it right the first time? Let’s talk.