What Is WCS (Warehouse Control System) Software?

The fulfillment area of your warehouse is comprised of a variety of functions, from inventory receiving and replenishment, to picking, packaging, transporting, shipping, sortation, and more. All of these discrete areas of the warehouse have a wide range of requirements, inputs, and outputs, as well as nuances based on the type of products and customers involved. These nuances all have to be managed by a central software that handles the hand-off between all of these various systems and the software databases that also manage each of these systems.

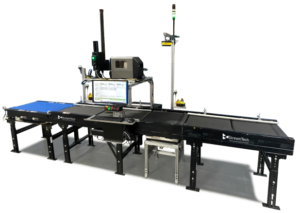

A WCS Warehouse Control System is a real-time, integrated control solution that manages the flow of items through the warehouse. They act as a traffic regulator for warehousing activities, with the mission of running material handling systems (and in some instances, the activities of workers). A good WCS system provides a broad, yet consistent interface for material handling systems like conveyors, carousels, palletizers, sorters, etc. This can result in great ROI for warehouses.

Key WCS Functions:

- WCS manages the operations of many types of material handling equipment

- WCS exchanges real-time communication of information

- WCS can synchronize the operation of automated systems, labor, and material

- WCS unifies the interface and control of automated equipment

- WCS focuses on one warehouse at a time

WCS sits in a layer that connects directly to automated equipment. It adjusts at the level of a single piece of equipment — and often through an entire facility. It can modify the behavior of shipping systems, conveyors, sortation, pick and pack automation systems, etc. WCS may also be integrated into wider essential systems to streamline warehouse management operations. For example, security devices like dome cameras, alarms, and access control systems may send real-time data to WCS, enabling stakeholders to receive automated alerts regarding security incidents.

If your warehouse were like a smart home – you have blinds, doorbells, cameras, garage doors, water sensors, light switches, TV’s, speakers. Would you rather have multiple apps on your phone to control every single one of these devices, or would you rather have one app where they’re all organized and controlled? This central control is the WCS for your warehouse.

What Software Connections Does It Make?

A successful automation system is about more than just hardware. Yes, the WCS manages picking, packaging, shipping and sortation equipment from a variety of different manufacturers, orchestrated perfectly together to meet your daily business requirements. However, in this digital age, we cannot overlook the software and database connections that the WCS must also make, to your WMS, ERP, order management and/or multi-carrier platform.

In a fulfillment automation application, in order for the hardware to perform tasks such as assigning weight, dimension data, pick status, packslip status, sort location or other information to an order, it must be connected to your multi-carrier or order management software. The connection to these platforms allows the data to be powerful enough to do things like rate shopping in real-time from the weight and dimension data, perform address verification, proof of delivery, and other important functions for your company and ultimately your customers. Read this excellent article from MHI’s Warehouse Automation Blog on other warehouse software, and how the WCS fits together.

What WCS Capabilities Should You Expect?

When looking at fulfillment automation integration partners, choose one who has a warehouse control software that is robust, proven, and that you can trust with your physical hardware and data. A warehouse control system (WCS) directs “real-time” activities within warehouses and distribution centers. They act as a traffic regulator for warehousing activities, with the mission of running material handling systems (and in some instances, the activities of workers). A good WCS system provides a broad, yet consistent interface for material handling systems like conveyors, carousels, palletizers, sorters, etc.

Some of StreamTech’s WCS features include:

- Realtime status of all shipped orders, including tracking ID, weight, dimension, etc.

- Sends data to and from the multi-carrier or order database (rate shopping, address verification, proof of delivery)

- Equipment status and error alerts (ie: printer, print head life, sensors, scales, scanners, etc)

- Configuration and management of sort lanes and locations

- Manages pack slip automation systems

- Manages picking systems

- Allows user management of multiple printer/applicators, and bypass if necessary

- Production reports – machine availability/uptime, boxes per hour, per week

- Data logging and exporting

- Response time reports

- Carton per minute reports

- Interface to HMI’s, can be shown directly within the software application

- Built-in browser, interfaces to any web-connected hardware

- Defined user roles – administrator vs. operator

- Built-in hardware troubleshooting test functions (test labels for printheads, boundary, other testing)

- Search by order, LPN, tracking number, category, status, lane etc.

If you are a warehouse worker or someone seeking warehouse job options, it’s crucial to be aware of Warehouse Control Systems (WCS), as they greatly enhance efficiency and organization within the warehouse environment.

StreamTech’s engineering and software development teams are constantly researching and incorporating new features to increase the capability of our WCS. For more information, or if you would like to discuss your fulfillment operation with us, please fill out the form below or give us a call.