Today we are going to be discussing the keys to developing an effective parcel sortation system.

In today’s fast-paced and rapidly evolving logistics industry, building an efficient parcel sortation system is crucial for streamlining operations and meeting customer demands. With a wide range of package profiles and sizes, finding the right sortation system becomes a critical decision for businesses aiming to optimize their order fulfillment processes.

Let’s explore the factors that go into selecting the right parcel sortation technology, to design a sortation system that will work for your operational needs.

Many Applications For Parcel Sortation Automation

Before we dive into the specific data points, it’s helpful to recap why sortation automation is helpful in the first place. Warehouse sortation systems are used for many applications, all to improve efficiency, accuracy, and throughput in the order fulfillment process. Here are some common applications for warehouse sortation systems:

- Order Consolidation: A parcel sortation system is used to consolidate individual items or products from different picking areas or zones into complete customer orders. This ensures that all the required items for an order are brought together in one location before packing and shipping, reducing the time and effort required for order assembly.

- Order Segregation: Sortation systems can separate different types of orders based on criteria such as destination, shipping method, priority, or customer requirements. This allows for streamlined processing and specialized handling of orders, enabling faster and more accurate fulfillment.

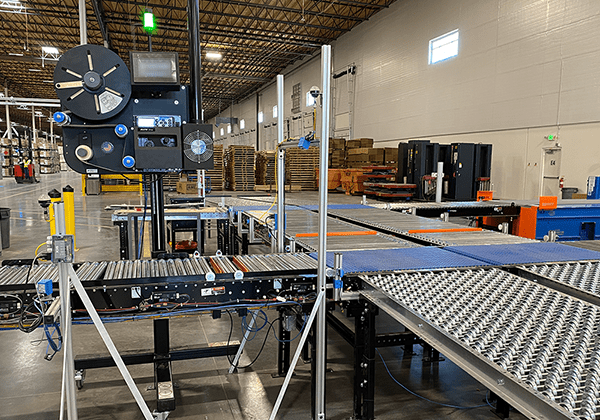

- Shipping Lane Allocation: Sortation systems can allocate specific print and apply shipping lanes or loading docks to different orders or carriers based on predetermined rules. This helps optimize the flow of goods through the warehouse and ensures that orders are directed to the appropriate outbound areas for efficient truck loading.

- Routing: A parcel sortation system can route products or items to different areas of the warehouse based on factors like product characteristics, customer location, or specific handling requirements. This ensures that items are directed to the appropriate processing areas or value-added services, reducing unnecessary travel within the facility.

- Product Sequencing: Sortation systems can arrange products or items in a specific sequence based on factors such as product codes, sizes, expiry dates, or production dates. This sequencing enables efficient picking and packing processes, especially for orders that require specific product combinations or staging for further processing.

- Returns Processing: Sortation systems can handle returned items by separating them based on the reason for return, product condition, or disposition instructions. This allows for proper inspection, restocking, refurbishment, or disposal of returned goods, ensuring efficient reverse logistics operations.

- Load Balancing: A parcel sortation system can distribute workloads evenly across different areas or resources within the warehouse, preventing bottlenecks and maximizing resource utilization. This helps maintain a smooth flow of goods through the facility and optimizes productivity.

- Parcel Error Diversion: Sortation systems incorporate barcode scanning, weight checking, and other technologies to ensure accurate identification and verification of products during the sorting process. Incorrect parcels are diverted to a jackpot area, or are recirculated to attempt a second run. The key benefit of diverting errors is that it allows the rest of your fulfillment process to continue running at speed. Without an error diversion system, the only way to handle an error event is to stop the whole system and manually fix the offending package.

Now that we understand some of the ways sortation is applied, let’s look at the factors needed to design a sortation system.

Understand Your Package Profiles

First, we should consider your package profiles. This refers to the characteristics that define your parcel variety such as the size, weight, shape, fragility, and contents of the package. Understanding this will help determine the handling requirements, sorting methods, and equipment needed to process and deliver the package.

- Envelopes: Envelopes typically have a flat and lightweight profile, ideal for documents, photo prints, letters, or small items. If envelopes are involved in sortation, it will be important to remember that the conveyance will require between-roller photoeyes that capture the envelope as it travels along the conveyor (envelopes are often thin enough that they go right under traditional side-mounted photoeyes). Also, if envelopes are involved, we can automatically assume the system will require top-mounted barcode scanners, to read ID information on the envelope.

- Boxes: Boxes come in various sizes, lengths, and weights. Some boxes are RSC’s with flaps, while others may be made by a case erector or other packaging equipment. The amount of variation in box sizes will be a major factor in sortation design. If boxes are all relatively small in size, and items inside are not fragile, they can simply fall into a gaylord off the sorter. If there’s a high variation and the items may be heavy, sortation to either gravity or roller conveyor is best.

- Polybags: Polybags are commonly used for packaging clothing, textiles, or soft goods. Polybags can present a sortation challenge, so we have a few technologies we employ that work well. The biggest challenge with polybags is to ensure the barcode is flat, and readable – not crinkled. Secondly, to make sure they sit flat, and have plenty of contact surface with the conveyor and sorter. A polybag that is thrown on a belt, and lands “standing up” will not work with automation.

- Pallets/Flats: Sorting palletized shipments will require a wide, high load capacity conveyor, and will require sortation technology that is designed to handle pallets. If the pallets are wrapped in plastic, it will be important to ensure the barcodes are still readable either through the plastic, or ideally placed on the outside of it.

- Large Items: Some packages have unique profiles due to their size, such as furniture, machinery parts, or large appliances. These items also require specialized conveyor and sortation technology designed to accommodate their dimensions and weight.

- Fragile Packages: items that are delicate, sensitive, or prone to damage require careful handling and may require additional protective measures, such as cushioning materials or special packaging designs. If the fragile items make up a very small percentage of your overall daily volume, in some cases it may be best to just keep these separated in a manual handling lane.

- Hazardous Materials: Items such as chemicals, flammable substances, or biohazardous items have specific regulations and safety requirements that must be followed during handling, sorting, and transportation. They also often require compliance labels to be adhered to the outside.

Example Video of Large Parcel Fulfillment

Size & Weight

It is also important to consider the overall dimensions and weight of your packages. Each sortation technology is designed to accommodate a certain weight, as well as a certain item shape. Small items may not function effectively in certain cases, while long items may also face challenges in other situations.

For example, a roller ball sortation system works well for a very wide variety of packages. However, if the items are small and lightweight, and do not have very many contact points on the sorter, they will not divert. As an integrator, we have experience with common challenges and pitfalls like this, and can help steer you toward the right technology.

Sortation Information

One of the most important elements to an effective parcel sortation system design is to clearly define the data exchange. There are a variety of data points that can be used to sort packages, and it’s important to know what you are trying to achieve.

Sort Codes & Shipping Server Connection

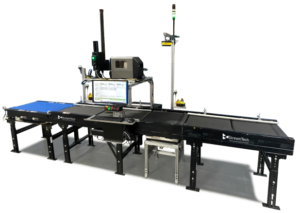

The most common method we use for sortation would be using a data exchange handshake with our software. Typically when a package conveys into the end-of-line fulfillment system (SLAM), we induct the package and send a data request to the shipping server (WMS, multi-carrier).

It contains the LPN of the package, and we request a shipping label as well as a sort code from the shipping server. The shipping server will send us both items, and we apply the label, and store the sort code in our database. This sort code is typically just a text string that the customer provides.

Once the package arrives at the sorter, we re-scan the LPN, and query our database for the sort code that we have been provided, and run the sort logic rules that we’ve put in place, accordingly.

Other Sortation Methods

- Barcode or Shipping Label Scanning: Packages can be scanned for barcodes or labels containing information about their destination or routing, and then they are sorted according to the software and logic-based rules built into the system. In some cases this information is contained in the LPN barcode, while in others this information can be contained in the carrier shipping label, which would be read after it’s applied (in this case, we often use the verification scan to double as the sort scan) This can work for:

- Zip Code or Postal Code Sorting

- Sorting by Service Level (express, overnight, etc)

- Sorting by Carrier (FedEx, UPS, USPS)

- Customer or Order Information (priority, high value, or VIP clients)

- Weight-Based Sorting: Packages can be sorted based on their weight, after traveling across the scale. Heavier packages may be directed to different conveyor belts or chutes than lighter ones.

- Dimension-Based Sorting: Packages can be sorted based on their dimensions (length, width, height). This method is especially useful for handling large or irregularly shaped items. In some cases clients prefer large boxes to go one way, small ones to go another.

- Routing Information: Packages may contain electronic tags or chips that convey routing information, allowing the sortation system to automatically route them to their designated destination. This can be effective for final mile routing companies.

Dealing With Sortation Delay

Sortation delay can occur due to various reasons such as system malfunction, connectivity issues, or unexpected surges in parcel volume. To mitigate the impact of sortation delays on operational efficiency and customer satisfaction, it’s crucial to implement strategies to address these challenges effectively.

- Real-Time Monitoring and Alerts: Establish a robust monitoring system that tracks the performance of the sortation process in real-time. Implement alerts that notify operators and supervisors immediately in case of any deviations from expected throughput or system malfunctions. This proactive approach enables swift identification and resolution of issues before they escalate.

- Troubleshooting Protocols: Develop clear protocols for diagnosing and resolving common issues that may cause sortation delays. Provide comprehensive training to staff members on troubleshooting procedures to ensure efficient problem-solving and minimize downtime.

- Backup Systems and Redundancies: Implement redundant systems and backup mechanisms to maintain continuous sortation operations even in the event of primary system failures. This may include backup power sources, redundant servers, or alternative sortation routes to reroute parcels when necessary.

- Dynamic Workforce Management: Maintain flexibility in workforce scheduling to accommodate fluctuations in parcel volume and operational demands. Utilize cross-training programs to equip employees with versatile skills that enable them to address various tasks during peak periods or when specific operational roles face constraints.

- Streamlined Communication Channels: Establish clear communication channels between different departments involved in the sortation process, including operations, IT, and customer service. Facilitate seamless information exchange to coordinate responses to sortation delays effectively and minimize disruptions throughout the supply chain.

- Continuous Improvement Initiatives: Regularly evaluate sortation processes and performance metrics to identify areas for optimization and efficiency gains. Implement continuous improvement initiatives based on data-driven insights to enhance sortation accuracy, speed, and reliability over time.

- Customer Communication and Transparency: Maintain open and transparent communication with customers regarding any potential delays in parcel sorting and delivery. Provide timely updates on the status of their shipments, along with realistic delivery expectations, to manage customer expectations and uphold service quality standards.

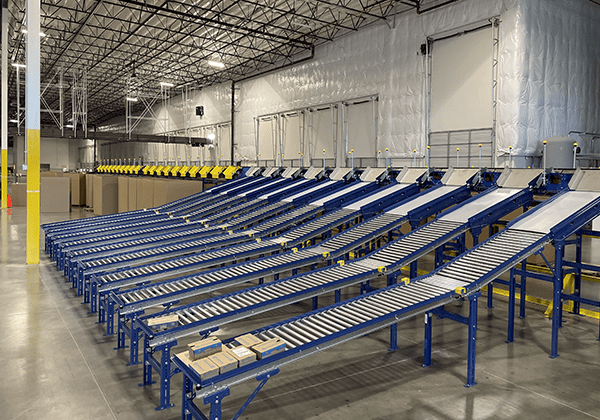

Throughput, Locations & Destination

The last and most obvious elements that need to be discussed when building an effective parcel sortation system are the speed target, number of locations, and end destination. These go hand-in-hand, and should be considered together. We need to know a daily or hourly throughput goal, so that we can ensure the sorter will operate at the speed required. In some cases, the throughput goal will require a high speed technology, additional diverters, or possibly additional lanes.

The final destination and the number of locations matters as well. If your packages are thin, light and not easily damaged, they can be dropped straight off the edge into a gaylord. In other cases, customers may ask us to direct packages to separate lanes to each dock door. Some customers even opt to employ truck loaders, guiding the packages straight into the truck itself.

Throughput is important for other reasons. For example, if customers opt to drop their items into 4 separate gaylords, and process about 10,000 packages a day, they might want to re-think it. There’s a limit to how much a gaylord can hold, and their employees will have to refresh the gaylords many times throughout the day. In this case, it’s best to just include more sort locations to evenly distribute the load (the goal is to reduce manual labor, not just move the labor to another bottleneck in your operation).

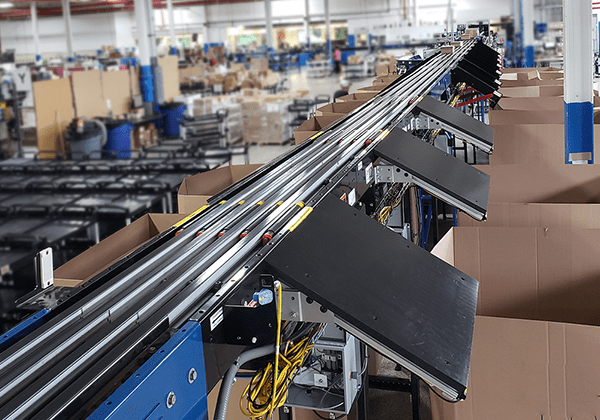

Sortation Technology & Final Design

At StreamTech, we offer a variety of sorting systems to accommodate different package profiles which include the ModSort®, Urethane Belt Transfer, PolySort, Narrow Belt, and custom options. StreamTech will help you design a system to meet your throughput, package profile, and will configure the controls and software to accomplish your goals. We will help select the right technology that fits your needs.

All of these elements are summarized in our helpful and easily downloadable Parcel Sortation Guide which you can share with your team as well.

Parcel Sortation FAQ

Q: What is the difference between a fulfillment center and a sortation center?

A: A fulfillment center is responsible for storing and shipping products, handling the entire order fulfillment process. On the other hand, a sortation center focuses specifically on sorting packages based on various criteria before they are further directed to their destinations.

Q: How long is package sorting?

A: The duration of package sorting can vary depending on factors such as the size of the facility, the volume of packages, and the efficiency of the sorting technology. There is no fixed timeframe, as it differs among different logistics operations.

Q: What comes after the sortation center?

A: After sorting, packages are typically directed to their respective destinations. They may be sent to specific shipping lanes, loading docks, or areas designated for further processing and transportation.

Q: What is a sortation delay?

A: A sortation delay refers to a situation where the normal sorting process is interrupted or delayed. This can occur due to various reasons, such as technical issues with sorting equipment, high package volume, or disruptions in the logistics workflow.

Q: Why is a package called a parcel?

A: The term “parcel” is often used interchangeably with “package.” It generally refers to a wrapped or packaged item for shipment. The word “parcel” has historical roots and is commonly used in the context of shipping and logistics.

Q: What is the difference between a parcel and a shipment?

A: A parcel is a single wrapped or packaged item, while a shipment typically refers to a collection of parcels or packages that are sent together as a group. A shipment can consist of multiple parcels bound for the same destination.

Q: What is the fastest sorting procedure?

A: The speed of sorting procedures can vary, and the fastest method depends on the technology and systems employed. High-speed automated sortation systems, such as those utilizing barcode scanning and conveyor systems, are often considered efficient for rapid sorting.

Q: How do I prepare a parcel to send?

A: To prepare a parcel for sending, ensure it is securely packaged and appropriately labeled. Use sturdy packaging materials, affix a shipping label with clear destination details, and adhere to any specific packaging guidelines provided by the chosen shipping service.

Q: Why is my package still at the sorting center?

A: Packages may stay at the sorting center for various reasons, including high volume, technical issues, or adherence to specific sorting schedules. Tracking information may provide updates on the package’s status, and delays are not uncommon during peak shipping times or unforeseen circumstances.