Estimated reading time: 7 minutes

We know that dealing with order errors in the fulfillment process can feel like a never ending battle. It’s frustrating, time-consuming, and, frankly, a bit disheartening when the hard work of your team doesn’t translate into flawless operations. Every mispicked item or incorrect order not only reflects on the team’s efforts but can also ripple out, affecting customer satisfaction and your bottom line. It’s the kind of challenge that can keep you awake at night, wondering how to tighten up those processes and ensure that what goes out the door is exactly what your customers are expecting.

At StreamTech, we specialize in enhancing warehouse accuracy and efficiency with smart, practical automation technologies – such as our pick-to-light systems. Designed to reduce manual order picking errors, the system relies on our WCS Picking Software and LED light devices to direct the operators. Our technology addresses key logistics challenges, improving both operational performance and customer satisfaction.

In this post, we’ll dive deeper into how to improve warehouse picking speed and accuracy through our Pick To Light system.

What Is A Pick To Light System?

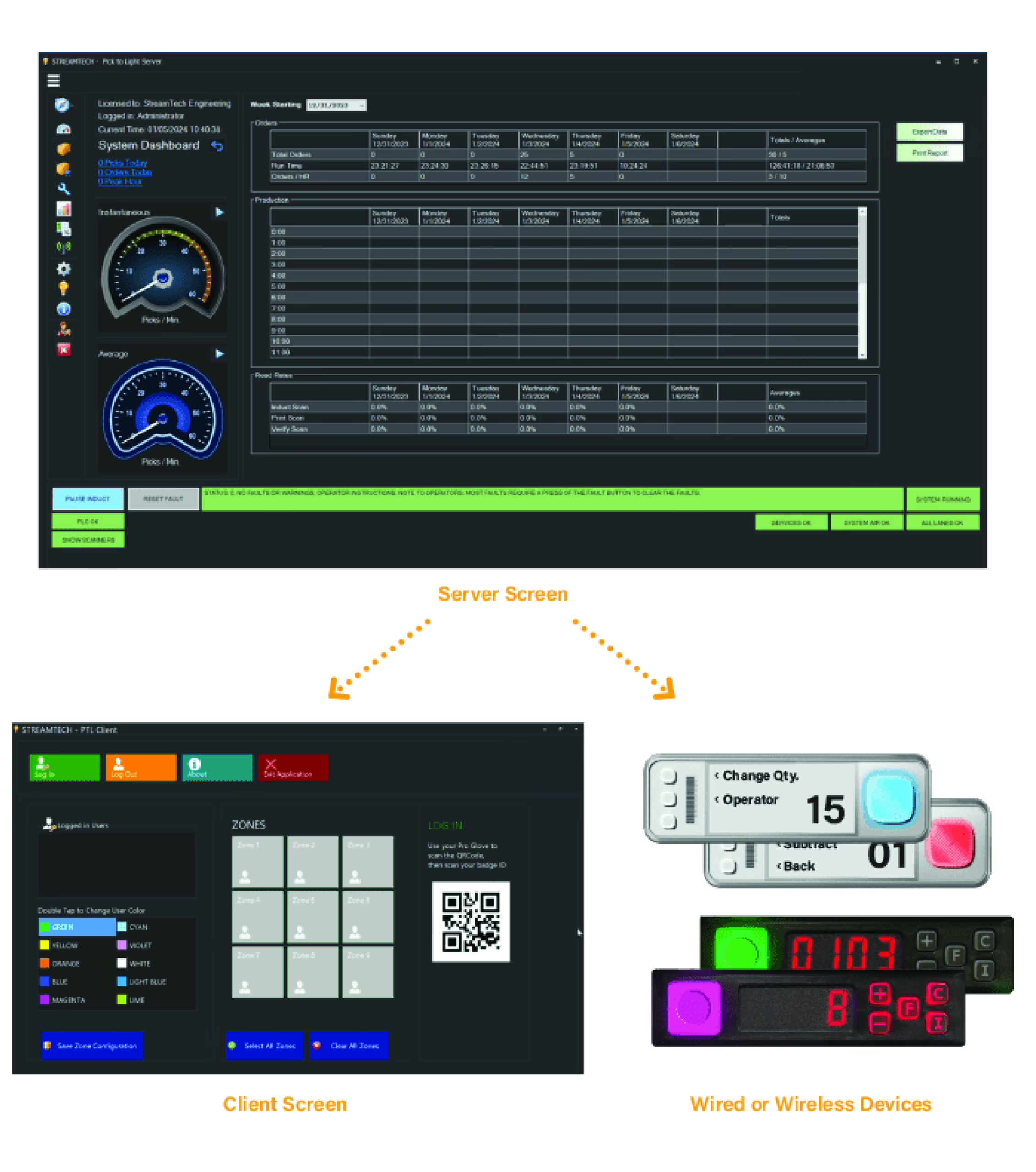

Our Pick-to-light system streamlines warehouse picking by guiding workers to item locations using illuminated displays on racks or bins. This approach combines sophisticated hardware that is integrated with our Warehouse Control System (WCS) software , to enhance fulfillment accuracy.

The system’s hardware includes light displays and sensors on storage locations. When an item needs to be picked, its corresponding light illuminates, directing the picker. After picking the item, the worker signals completion by pressing a button or triggering a sensor, telling the system to move on to the next item. This direct feedback loop ensures a smooth and efficient picking process which can increase the pick rates per person.

The other crucial component involved is the software. The WCS Picking Software is connected to the customer’s Warehouse Management System (WMS) software, and the two software platforms work in close conjunction with one another. While the WCS Pick Software manages the hardware LED devices and screens, the WMS manages the orders and the most efficient picking routes. It dynamically adjusts to changes, managing multiple orders and maintaining real-time inventory accuracy. Integration with the WMS is seamless, allowing for instant updates and analytics, which are essential for optimizing operations.

Learn more about our WCS software ›

Key components like light displays, sensors, and barcode scanners are central to the system’s functionality. Barcode scanners add an extra layer of verification, ensuring the right item is picked to help keep inventory records precise.

Picking Automation Strategies:

There are a few different ways we can employ this picking system. It all depends upon how each customer’s warehouse is structured, how the orders are fulfilled, and what fits best with the flow of the operation.

Velocity Picking Mod:

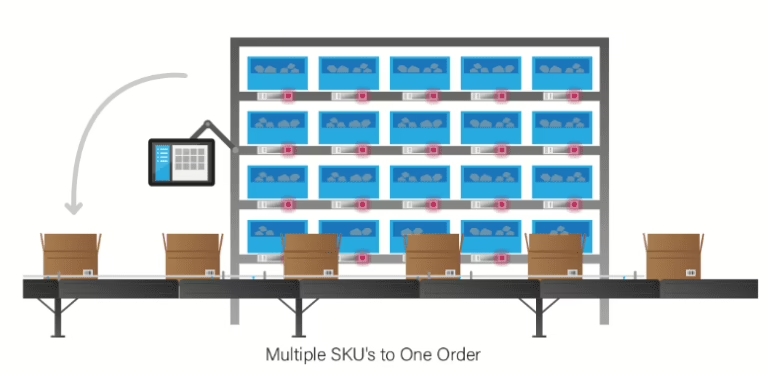

The light directs the picker which bin location to retrieve from the inventory rack. Typically in this configuration, a conveyor system is positioned along an inventory picking rack, which is filled with “high movers” – the most commonly picked items. An empty carton progresses along the conveyor, and when inducted by a scanner, the lights signal on the bin location, along with a quantity shown on the display.

Wireless Smart Carts:

The lights direct the picker which empty carton to place the items in. The operator pushes the smart cart to the correct aisle and bin location, and uses a gloved hand scanner to scan the bin location (as a verification step). The lights on the cart correspond with empty orders that need to be filled. When the inventory bin is scanned, the light devices indicate both a quantity on the display, and a location.

Put to Light (Put Wall):

This is used in reverse logistics, returns processing or inventory replenishment. It can also be used for simply sorting and storing orders until they are completely picked, to be processed in batches. In this method, workers start by scanning items, instead of empty order cartons. When an item is scanned, the system directs the worker to the appropriate location for restocking. Lights indicate the specific rack and bin location where the item should be placed.

How Does The Pick-to-Light System Reduce Errors?

Now that we understand how the Pick-to-Light system works, it’s time to explore all the ways that it can help increase accuracy and improve picking rates (or speed).

Increasing Pick Accuracy

By lighting up the exact location of the item that needs to be picked, the Pick-to-Light system helps take human errors out of the equation. Warehouse employees no longer need to second-guess if they’ve grabbed the right product or waste time squinting at product codes. When the light goes on, your team knows exactly where to go and what to pick. We have two different methods for this, depending upon the type of pick-to-light implementation:

Training and Learning Curve

Traditionally, training pickers can be a time-consuming process with the complexities of warehouse operations and the daunting task of memorizing product locations. Pick-to-light systems help make the onboarding process smoother and quicker, as new team members simply need to follow the lights. This reduces training time significantly and allows new employees to become productive members of the team faster than ever.

Enhancing Inventory Management

Keeping track of inventory can feel like trying to solve a complex puzzle with pieces that constantly move. A Pick-to-light system simplifies this challenge by providing real-time updates every time an item is picked. The tight connection between the WMS and the StreamTech WCS Picking Software provides a constant flow of information that keeps inventory levels accurate, reducing the chances of stock discrepancies that can lead to overstocking, stockouts or mis-picks.

Improving Order Fulfillment Speed

In today’s fast-paced market, speed is of the essence. Customers expect their orders to arrive yesterday, and pick-to-light systems are how we meet those expectations. By streamlining the picking process, orders are fulfilled faster, leading to quicker turnaround times and happier customers. It’s a direct link between the efficiency and effectiveness of your operations and the satisfaction of your customers, showing that when you invest in making your processes better, everyone wins.

Example:

An eCommerce business specializing in apparel and accessories turned to a pick-to-light system to tackle its growing issue of order inaccuracies. Before the implementation, the company faced a significant challenge with order fulfillment errors, leading to customer complaints, returns, and exchanges that not only impacted customer satisfaction but also inflated operational costs.

Our Pick-to-Light system was integrated into their existing warehouse management system, providing a seamless transition that immediately began to show results. Each picking station was equipped with light indicators and sensors, guiding warehouse staff directly to the correct products and quantities required for each order. This visual guidance system significantly reduced the likelihood of shipping errors.

Within the first quarter of implementation, the company reported a remarkable reduction in order fulfillment errors—down by over 60%. This improvement was directly attributable to the accuracy provided by the pick-to-light system.

The company also observed a notable increase in order fulfillment speed, with order processing times reduced by nearly 30%. This efficiency gain not only enhanced customer satisfaction through faster delivery times but also allowed the company to handle a higher volume of orders without additional labor costs.

Ready to Reduce Errors With Pick-to-Light?

At StreamTech, we’re all about looking for ways to improve efficiency and streamline e-commerce fulfillment, especially when it comes to our pick-to-light system. We craft solutions that solve issues at their core and are customizable to fit seamlessly into your operations. Through a blend of expert advice and innovative engineering, we’ve guided many businesses toward smoother operations, bolstering both the reliability and efficiency in their supply chain processes.

Let’s explore how we can do the same for you, making your operations faster, and more accurate – to the delight of your customers.