Estimated reading time: 10 minutes

Since the late 1990s, eCommerce has evolved from a novelty into a dominant force in global retail, driven by advancements in secure online payment systems and logistics technology. As consumers prioritized convenience and cut back on trips to physical stores, businesses responded with more advanced e-comm stores, and increasingly automated fulfillment operations to keep pace with rising demand.

This shift has accelerated the adoption of robotics, advanced inventory management systems, and high-speed order processing, making fulfillment faster and more precise. In this post, we’ll examine the latest innovations in warehouse automation and their impact on the future of e-commerce.

What’s Driving Warehouse Fulfillment Automation in 2025

In 2025, warehouse operators must adapt to rapidly changing customer expectations and technological advancements or risk falling behind. Here are the top trends shaping the future of warehousing:

1. Robots & Their Implications On Picking Speed & Storage Density

Shelf-To-Person/Goods-To-Person Picking

The warehouse fulfillment automation industry was caught off guard in 2012 by Amazon’s acquisition of Kiva Systems for about $775M. Since then, many companies have tried to fill the gap and have developed new innovations.

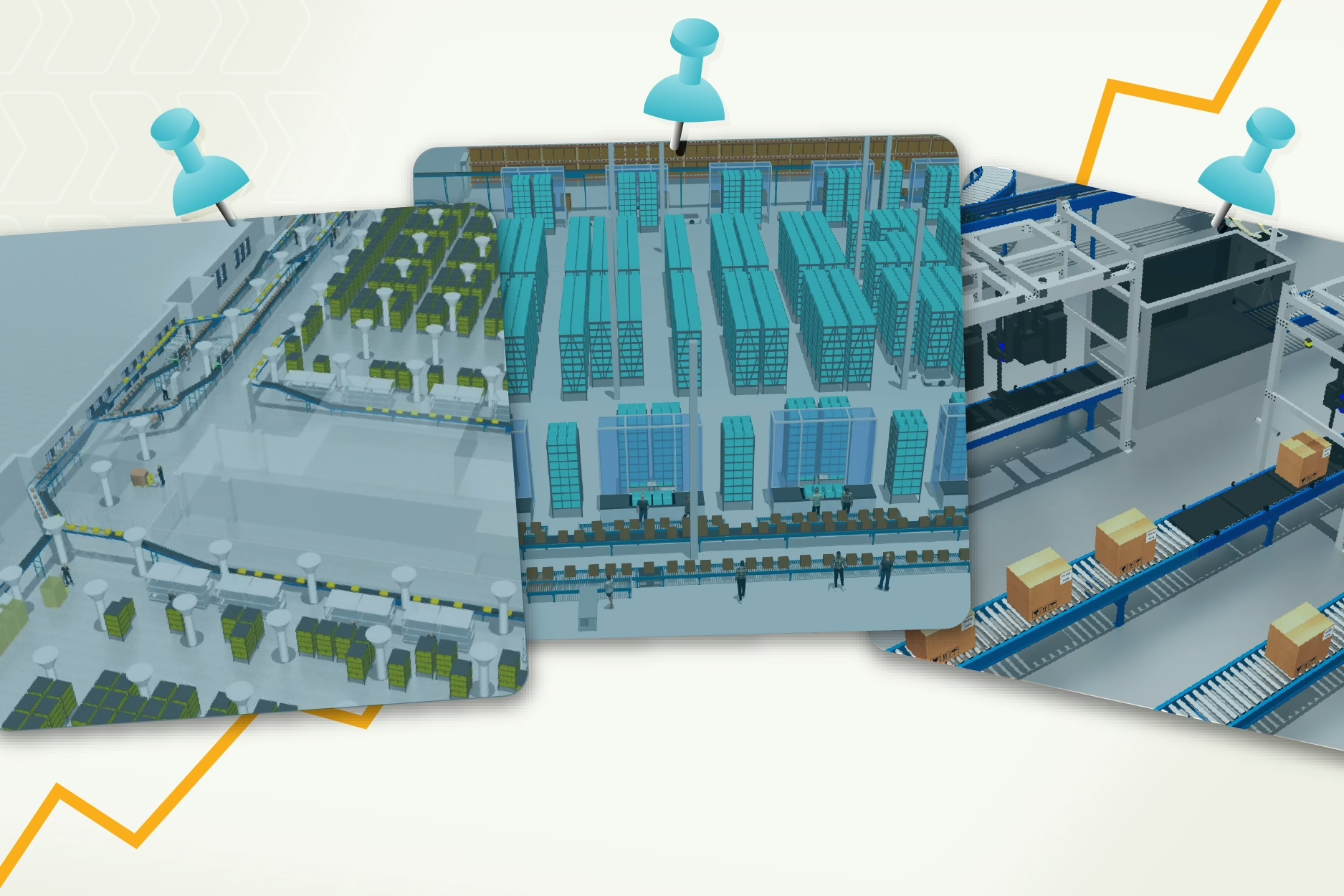

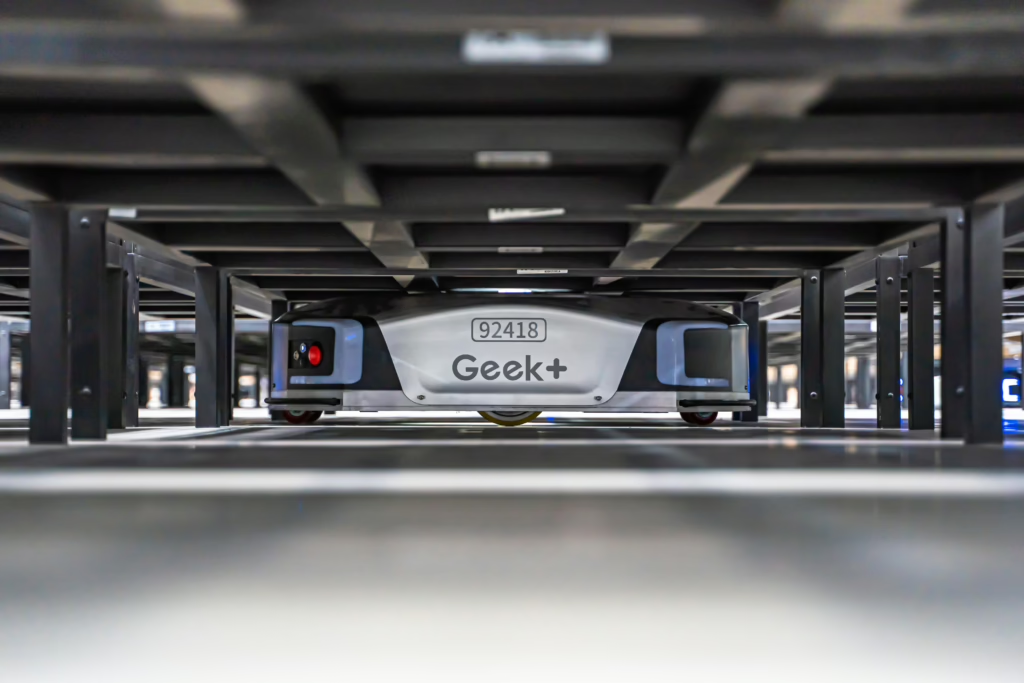

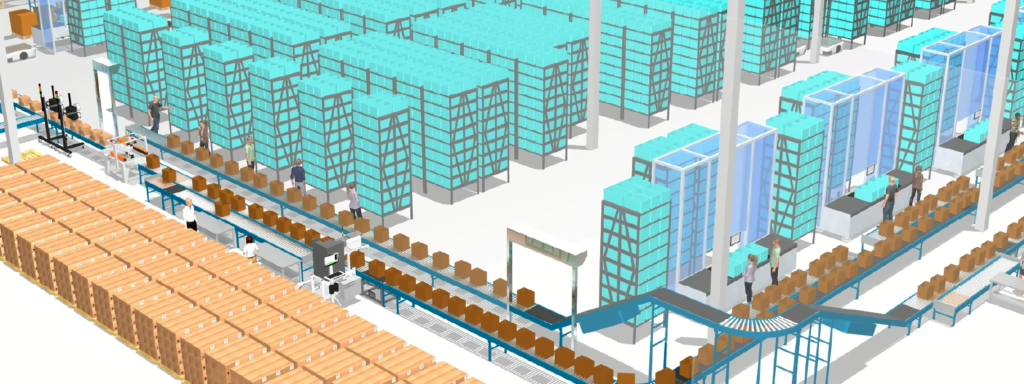

As automation is expected to see more widespread use in 2025, many businesses are taking small, targeted steps to enhance their operations. Mobile shelving—also known as shelf-to-person or goods-to-person picking—is set to become more common. These robotic systems can move physical shelving within the warehouse, bringing items to the picking staff, offering a practical way to boost efficiency without overhauling entire systems.

This advanced approach utilizes automated mobile robots (AMRs) to bring inventory shelves or pallets directly to centralized picking stations. By removing the need for humans to traverse the aisles retrieving items, shelf-to-person systems “check all the boxes” for the challenges that warehouse operations professionals are looking to solve:

- Reduce reliance on manual labor – Goods-to-Person robotics automate the retrieval and delivery of items, significantly decreasing the need for manual walking, lifting, and searching, allowing employees to focus on higher-value tasks.

- Accelerate picking speeds – By bringing inventory directly to the operator, these systems eliminate travel time within the warehouse, enabling faster order fulfillment and reducing bottlenecks in high-demand periods. The software also slots multiple picks per rack presentation, further increasing pick speed and efficiency.

- Minimize errors – With precise robotic handling and software-guided picking, the chances of human errors, such as mispicks or misplaced inventory, are greatly reduced, ensuring higher order accuracy.

- Maximize storage density and efficiency – Robots travel beneath the racks, eliminating the need for aisles and allowing for a higher concentration of storage locations within the same square footage. By dynamically rearranging inventory based on demand, they further optimize vertical and horizontal space, maximizing warehouse capacity without requiring expansion.

Powered by software intelligence that directs the robots, handles the slotting of the racks according to priority, and manages the flow of orders through the system, these systems are able to increase pick speed by achieving multiple picks per rack presentation to the operator. The bots operate continuously, adapting to changing demands in real time, re-arranging the racks according to order volume and seasonality.

By taking this focused step toward automation in 2025, businesses are addressing rising order volumes and labor challenges while positioning themselves for long-term success.

2. The Power Of A Solid Warehouse Software Stack

ERP + WMS + TMS + WCS

Seamless integration between ERP, WMS, TMS and WCS software ensures real-time data flow, enabling optimized inventory management, efficient order fulfillment, cost-effective transportation, and synchronized warehouse automation for maximum operational efficiency.

Getting this software stack right is becoming increasingly important. The ERP (Enterprise Resource Planning) system centralizes business data, providing accurate inventory and order information that feeds into the WMS (Warehouse Management System) for precise stock tracking, picking, and storage optimization. The WMS then communicates with the TMS (Transportation Management System) to ensure efficient shipping decisions based on order destinations, carrier rates, and delivery timelines. The TMS works alongside the WCS (Warehouse Control System) to synchronize material handling automation, such as conveyors and sortation systems, ensuring seamless movement of goods from storage to outbound shipping.

While businesses have relied on Warehouse Management Software (WMS) for years, forward-thinking managers are now choosing software that works more precisely for their unique operations. Enter Warehouse Control Software (WCS): the brain of modern fulfillment.

Unlike WMS, which provides high-level inventory management, StreamTech’s Warehouse Control System (WCS) Software serves as the central hub of your fulfillment automation, seamlessly integrating and synchronizing various material handling systems within your warehouse.

By acting as an intermediary between hardware automation equipment, control systems, and your order database, it ensures real-time management of operations such as picking, packing, shipping, and sortation. This centralized control facilitates efficient data flow and coordination enhancing overall operational efficiency. Additionally, StreamTech’s WCS software offers real-time monitoring capabilities, providing immediate insights into system performance and potential issues, which is crucial for maintaining smooth and efficient warehouse operations. StreamTech’s WCS, for example, offers:

- Real-Time Oversight: Constantly monitors equipment and processes, providing alerts and live updates for seamless operations.

- Dynamic Adjustments: Adapts workflows on the fly by modifying sortation rules, updating label templates, or redirecting printer signals.

- Integrated Insights: Logs every order and tracks performance metrics through dashboards and reports, helping warehouses identify inefficiencies and optimize processes.

This year we are seeing more warehouse operators seeking a solution for more stringent demand forecasting, inventory control, and supply chain transparency. Software is the answer.

3. Dimensional Accuracy: The Key To Smarter Fulfillment

For Inventory, Packaging, And Shipping

We can’t predict how the economy will shift this year. That’s why this is the year to focus on what you can control: Precise dimensional (DIM) weight measuring. While it might seem like a small detail, getting accurate measurements of your packages for shipping can have a surprisingly large impact on your bottom line.

Dimensional Accuracy In Inventory

In a fulfillment automation warehouse, dimensional accuracy is key to optimizing storage, slotting, and order processing. Precise measurements ensure the WMS allocates space efficiently, preventing wasted capacity and incorrect packing decisions. Inaccurate dimensions can lead to delays, increased costs, and potential product damage.

Cartonization and Right-Size Packaging

Cartonization selects the optimal box for an order, reducing waste, shipping costs, and packing time. Right-size packaging ensures products fit securely while minimizing material use. Automated systems improve this process, enhancing efficiency and sustainability by lowering excess packaging and shipping volume.

Advanced right-size packaging systems, such as trey erectors, random carton erectors, or robots that select the appropriate carton based on the order, take this a step further by constructing boxes to fit the exact dimensions of the items inside. These systems eliminate the need for excess void fill, reduce material costs, and optimize dimweight for shipping. With growing environmental concerns, legislation may soon require businesses to use packaging that closely matches product dimensions, pushing fulfillment centers to adopt automated right-sizing solutions to stay compliant and cost-efficient.

Dimweight For Outbound Shipping

Dimensional Weight (dimweight) affects shipping costs, as carriers charge based on volume, not just weight. Oversized boxes increase fees, making dimweight optimization crucial. Accurate dimensions and automated cartonization help minimize costs, ensuring efficient, cost-effective shipping while maintaining package integrity.

By automating DIM weight calculations, businesses can leverage thorough data, eliminate human error, and move faster. Equipment like StreamTech’s Sprinter™ can scan, weigh, measure dimensions, and print and apply labels for between 600 and 1,000 boxes per hour, without making a mistake. This level of automation allows you to:

- Reduce Costs: Optimize DIM weight to avoid overpaying carrier fees.

- Avoid Chargebacks: Eliminate penalties from inaccurate or incomplete data.

- Boost Efficiency: Automate processes like scanning, weighing, and labeling.

- Optimize Packaging: Minimize wasted space with smarter cartonization.

- Choose Smarter Shipping: Enable real-time carrier rate comparisons for cost savings.

In 2025, leading businesses are taking control of the aspects they can, and DIM weight automation is a simple yet powerful first step.

4. The Rise Of Personalized Order Experiences

Last, But Ultimately The Most Important

All of the above trends are designed to accomplish our last trend – delightful experiences for the end customer. Each year brings an increased demand for, and ability to, customize each shipment for the end customer. Personalization in packaging, shipping, and delivery is no longer a luxury—it’s a driver of customer satisfaction and loyalty. Leveraging subscription box packing software, warehouse technology, and data, businesses are enhancing the unboxing experience in 2025.

Branded packaging and personal touches, for example, create memorable unboxing moments. Right-sized packaging machinery with inkjet printing can feature logos, colors, and custom messages, while automated systems add personalized notes or full-color inserts that make customers feel valued.

Loyalty program integration takes engagement further by including QR codes or labels on packaging that link to loyalty accounts. Customers can check points, redeem rewards, and access exclusive offers. Inserts highlighting member-only events or benefits enhance exclusivity and encourage repeat purchases.

Product information inserts build trust by offering usage tips, care instructions, or brand stories within the packaging. These additions educate customers and deepen their connection to the brand.

Personalized delivery windows add convenience, especially for subscription services. By integrating advanced Transportation Management Systems (TMS) with customer data, businesses can offer flexible delivery schedules tailored to individual preferences.

In 2025, customers are no longer viewing customization as an enhancement; it’s an expected component of a meaningful customer experience.

Key Takeaways

- Robotics improve speed and space efficiency: Goods-to-person and shelf-to-person systems reduce travel time, increase pick rates, and allow higher storage density by eliminating the need for aisles.

- Software integration drives performance: Seamless communication between ERP, WMS, TMS, and WCS platforms enables real-time data sharing, operational visibility, and improved forecasting.

- Precision matters: Automated dimensional measurement and right-size packaging optimize costs, reduce waste, and prevent chargebacks by ensuring accurate data and efficient packaging.

- Personalization is the new standard: Customers now expect customized packaging, branded inserts, and flexible delivery windows, making automation essential to deliver tailored experiences at scale.

- Smart investments create long-term advantage: Automation built around accurate data and thoughtful design strengthens efficiency, lowers operating costs, and enhances customer loyalty.

- StreamTech leads in practical innovation: From robotics and software integration to right-size packaging systems, StreamTech delivers scalable solutions that help fulfillment centers adapt and grow confidently.

Moving Forward With Warehousing Innovation

Warehouse fulfillment has always been a center of innovation, and in 2025, the pace will only accelerate. By embracing automation trends such as DIM weight optimization, shelf-to-person picking systems, Warehouse Control Software (WCS), and personalized order fulfillment, businesses can stay ahead in an increasingly competitive e-commerce landscape.

StreamTech is at the forefront of these innovations, helping businesses implement cutting-edge solutions tailored to their specific needs. Ready to embrace the future of warehousing? Contact us today to discuss how we can help you stay competitive and efficient in a rapidly changing market.