Automation Tailored for Apparel Fulfillment

Ensure every order ships fast, accurate, and on-trend.

Delivering Style to Every Customer.

In the fast-paced world of clothing and apparel, automation can be the key to delivering speed, accuracy, and standout customer experiences.

From high-SKU picking to efficient packing and sortation, StreamTech solutions help apparel brands and retailers reduce manual labor, minimize errors, and handle seasonal or promotional surges with confidence – all while maintaining the precision and presentation today’s customers expect.

How Automated Fulfillment Transforms Apparel Operations

Real-Time Software Integration Keeps You Ahead

StreamTech’s light WCS software integrates in real time with order systems, giving you live visibility into order flow, inventory, and shipping — so you can monitor performance and keep customers informed with accurate updates.

Easily Personalize Every Apparel Order

Automate the inclusion of branded pack slips, promotional inserts, or special gift messaging — giving every order a personal touch that matches your brand promise without slowing down your fulfillment speed.

Reduce Labor Strain and Fulfillment Costs

Automated picking, labeling, and sorting reduce the need for manual labor on repetitive tasks, helping you manage labor shortages, lower operational costs, and reallocate staff to value-added roles like quality control.

Automate Pick and Pack for High-SKU Apparel

Handle complex SKU mixes with automated picking and packing that ensures efficient routing, accurate dunnage use, and streamlined cartonization — making it easy to manage everything from T-shirts to multi-piece outfits.

Speed Up Fulfillment and Optimize Shipping Costs

Automate end-of-line shipping with consistent operational speed, no matter the order volume. Built-in carrier rate shopping ensures you select the most cost-effective shipping option, reducing last-mile expenses.

Deliver Branded, Right-Sized Packaging

Modern packaging systems automatically right-size cartons to fit each apparel order, adding custom branding or logos to create an elevated unboxing experience — while cutting shipping costs and reducing material waste.

See How Mason

Companies Continues to

Grow with Automation

Mason’s continued growth initiatives and diverse product offerings required multiple fulfillment systems and packaging equipment. Now, Mason’s expansion has brought all their brands under one fulfillment and distribution center.

Your Smart Warehouse Starts Here

From sorting or labeling polybags to robotic picking automation, we build fully automated warehouse solutions tailored to the fast-paced world of clothing and apparel. We’ll help you reduce errors, speed up fulfillment, and scale with ease—no matter the season.

Transform Your Picking Strategy

Goods-to-Person picking can revolutionize apparel.

Goods-to-Person robotic picking streamlines apparel fulfillment by delivering items directly to workers, reducing walk time, increasing accuracy, and boosting order throughput. It’s a smart, scalable solution for faster, more efficient picking.

Add the Personal Touch—Automatically

Custom inserts, gift notes, and branded collateral made easy.

Whether it’s seasonal lookbooks, brand postcards, care instructions, or gift messages, apparel fulfillment demands more than just fast packing. Automating document and insert handling ensures every order feels intentional and accurate—without slowing down your operation.

Automate Shipping with Style

Dim, Weigh, Label—Faster Than Ever

With StreamTech’s shipping automation systems, you can capture dimensions and weight on the fly, feed that data to your TMS for real-time rate shopping, and apply the correct label—all at up to 15 CPM. Perfect for apparel operations shipping everything from delicate accessories to oversized outerwear.

Real-Time Data That Matches the Speed of Fashion

WCS software that connects every order stage.

StreamTech’s light WCS software integrates directly with your existing systems to deliver real-time order updates as garments move through picking, packing, and shipping. Sync inventory and order status back to your brand clients and give them the visibility they expect—without disrupting your current workflows.

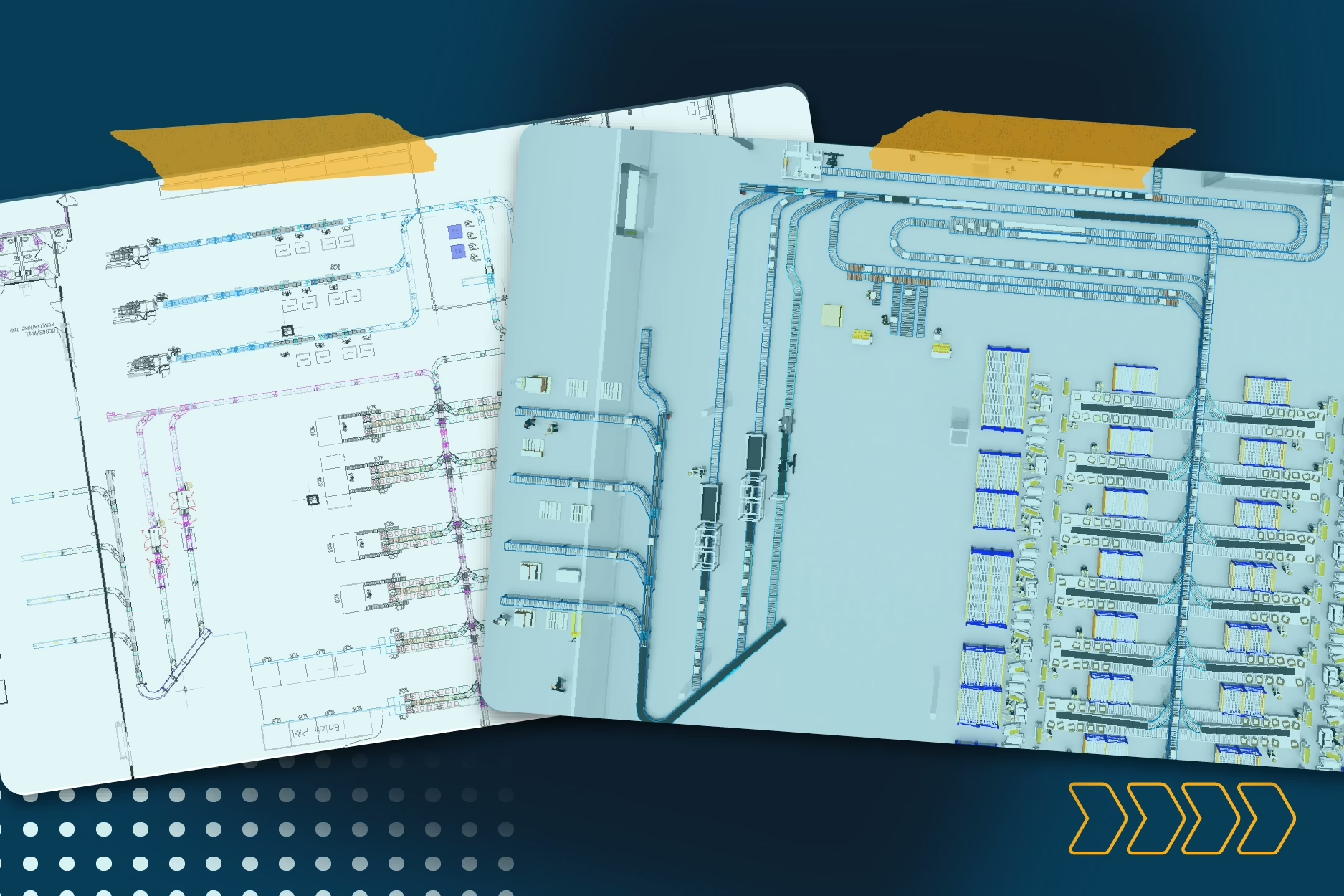

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

Can StreamTech’s automation handle a high mix of SKUs and seasonal fluctuations?

Yes. We know the apparel industry often deals with a high number of SKUs, constantly changing inventory, and seasonal spikes in demand. Our automation systems are built to adapt to this level of complexity. From diverse product sizes and packaging needs to shifting order volumes, we design scalable solutions that flex with your business—whether you’re launching a new collection or handling peak-season chaos.

We sell both high-end and budget-friendly apparel. Can automation be customized to support different product types?

Definitely. Our systems are not one-size-fits-all. Whether you’re dealing with delicate fabrics, bulky outerwear, or high-velocity basics, we design automation workflows that handle each item appropriately. We can prioritize speed for certain lines and add extra protection or packaging customization for premium products—ensuring that every piece arrives in perfect condition and aligns with your brand standards.

Will automation eliminate the ability to personalize our packaging?

Not at all. We know that packaging is an extension of your brand, especially in apparel. Our systems can include branded materials, marketing inserts, custom packing slips, and even variable packaging sizes—automatically. You’ll maintain a consistent unboxing experience while saving your team from manual packing tasks.

How long does it take to implement a warehouse automation system?

Implementation timelines vary based on the complexity of the solution, the size of your facility, and the integrations required. On average, projects can take anywhere from a few months to under a year. We take a phased, collaborative approach—starting with detailed planning and design, followed by installation, testing, and training—to ensure your team is confident and your system is fully optimized before go-live.

What happens if one part of the system goes down—does it shut down the whole line?

No. We design with flexibility and fail-safes in mind. If one module experiences an issue, the rest of the line can continue to run, minimizing downtime and disruption. Plus, our team offers remote diagnostics and fast support, so we can troubleshoot and resolve issues quickly—often before they impact your operations.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields