The Problem:

Not having automated sortation typically leaves you with two options:

- Limit shipments to a single carrier (which prevents the need for sortation)

- Invest in many people resources to take care of manual sortation.

Limiting shipments to one carrier will limit your shipping options, and therefore any cost savings associated with rate shopping. However, hiring too many resources to take care of manual sortation costs money and in some cases will wash out the savings from using a multi-carrier. In the end, manual sortation limits your ability to save costs on shipping which makes automation the optimal solution.

Our Solution:

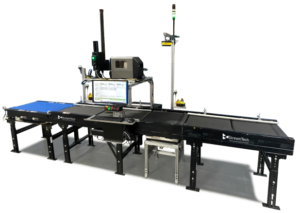

At StreamTech, we offer many different automated sortation solutions for different product types, different volumes, and different sortation rules. The product types that we can sort include boxes, padded mailers, irregular objects, and even flat objects. The volumes range from as low as 15 packages per minute up to 120 packages per minute. The number of lanes has no minimum or maximum limit – and the sortation rules are modular. This means a customer can develop as few or as many sort codes as they please.

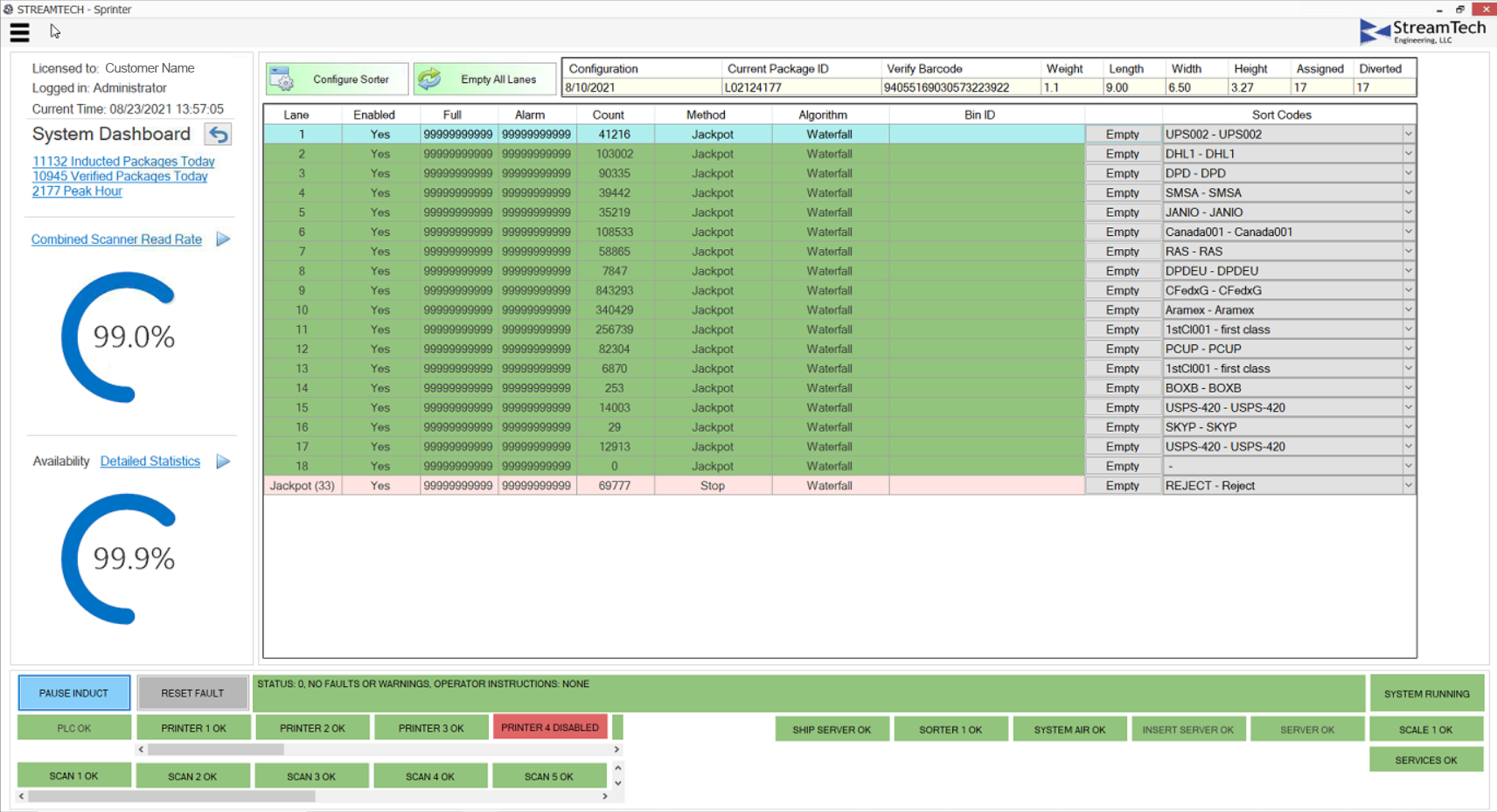

Our warehouse control software package allows the customer to program their sort codes into the software and then distribute them to whichever lanes are appropriate. Lanes can have more than one sort code in one lane, but also one sort code can be placed into multiple lanes. Our software will automatically send packages to a second lane if the lane fills up by package count or by a physical sensor. This gives the operator an easy-to-manage time frame to switch out a full bin.

(Example StreamTech WCS Sortation Screen, Installations)

Every sorter also comes with a reject lane, also sometimes called a “jackpot” or “hospital” lane. This is necessary so the sorter has a place to send packages that are not ready to ship. This can happen if the wrong label is on the package, if the package does not have a label, or if the barcode scanner simply could not read the label. It is our goal that this reject percentage is less than 1% of total production. These parcels can be manually assessed and sorted, or they can be brought back around and run a second time through the sorter to give the automation another opportunity.

A new available option that strengthens the accuracy of the sorter is open lid detection. We offer an open package detection system that can flag open packages and either stop them in their place or sort them to the reject lane. Open package detection is important because an open package that properly sorts will lead to a customer not receiving their order. However, your WMS will have it listed as shipped because it successfully sorted, but the package contents will have been dumped out and the carrier will not deliver it. This leads to an unhappy customer, and can be avoided with technology.

Learn more about StreamTech’s sortation technologies, or get in touch with us today to discuss your project.