Pre-Engineered: Built for Throughput

Scan it. Weigh it. Label it. Ship it. Done.

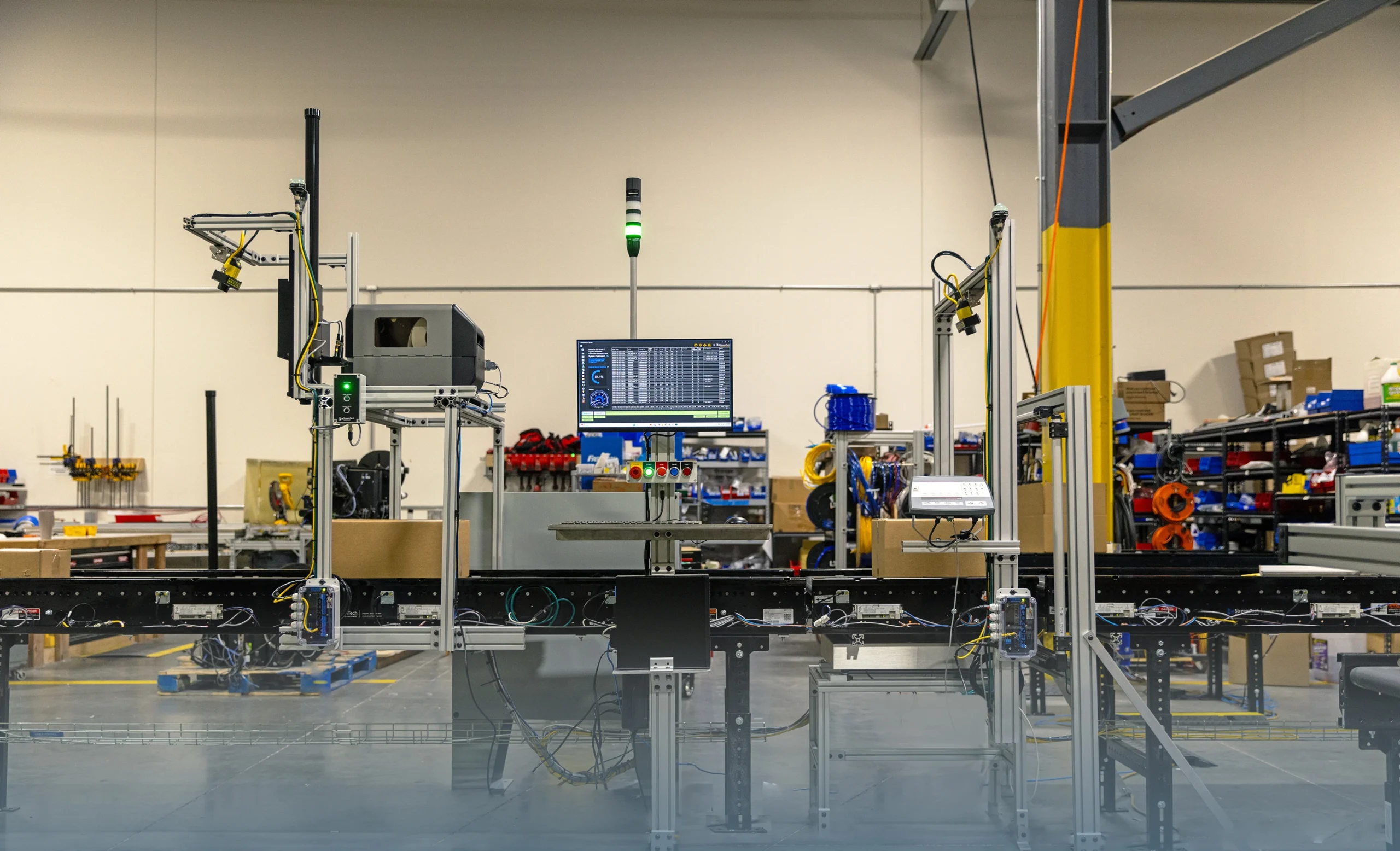

The Sprinter is all‑in‑one print and apply labeling system that scans, weighs, dimensions, prints, and applies labels while integrating with multi‑carrier software or your ERP. It also handles manifesting and verification in real time.

Reliably identify each package, capture weight and dimensions, print, apply and verify the carrier label. Interface with your ERP or multi-carrier shipping software. Built and tested in our facility. The Sprinter™ is pre-wired and ships complete. Position it in your facility, connect to data and plug it in for a turn-key shipping system that meets your needs. Its on-board software manages the process, providing host interface options, configurable data retention and rich maintenance diagnostic and test functions. Multi-level operator login capability with administrator and super user control.

Forgives Latency Issues – Uses Zoned Accumulation Conveyor

The Sprinter print and apply labeling system takes advantage of zoned accumulation conveyor. This means the packages are neatly singulated within each of the zones of the conveyor, allowing for the package to wait at any stage in the process in the event of a latency issue. This makes the Sprinter very forgiving for inconsistent software response times.

Consistent Results – Proven, Pre-Vetted Components

The labeler, the conveyor style, the scale, the dimensioner – all have been chosen and pre-engineered to work well with one another. While highly customizable, the core materials of the Sprinter are pre-engineered and have been proven in hundreds of installed systems. The Sprinter also has a standardized controls framework.

Reduces Downtime – Fast Install in Days, Not Weeks.

The Sprinter print and apply labeling system is assembled in our shop, factory tested, and then shipped to your facility. Typically installation and commissioning can be done in only 3 to 5 days. Weekend installation is available upon request.

How The Sprinter™ Works

The Sprinter™ is a fully automated scan, weigh, dimension, and print and apply system designed to transform end-of-line shipping operations. By capturing precise package data and eliminating manual labeling, the Sprinter™ helps fulfillment centers keep pace with rising order volumes and complex carrier requirements.

With its seamless integration to warehouse software, the Sprinter™ print and apply labeling system improves speed, accuracy, and throughput while reducing labor costs and errors. It’s an essential tool for operations looking to optimize shipping processes and deliver consistent, on-time performance.

Sprinter Delivers Consistent Results

7k

Orders Per 8hr Shift

15

Cartons Per Minute

3-5

Day Installation

Configurable to Your Operational Needs

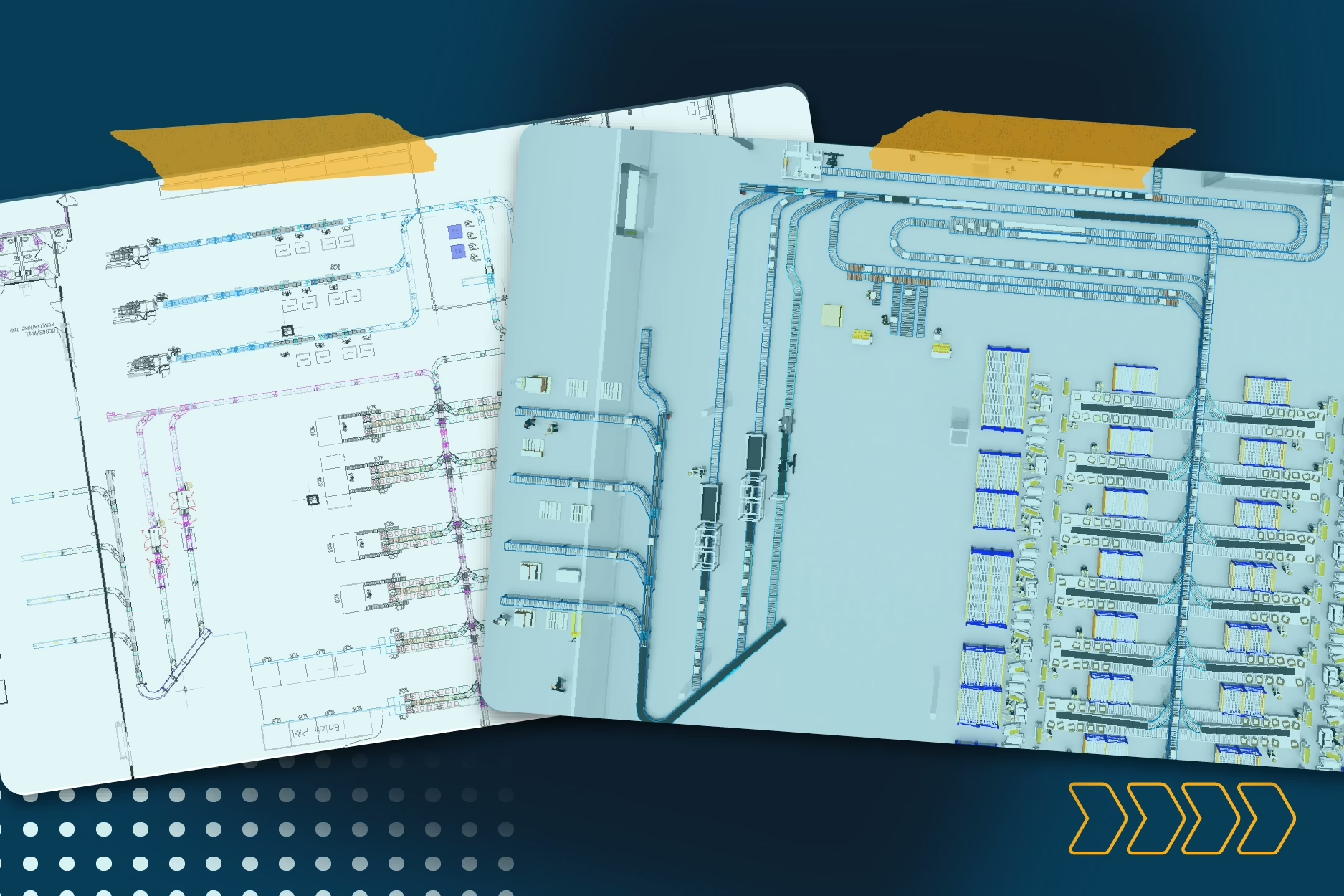

Distribution Fulfillment with Taper, Extendable Conveyor

For this distributor, the Sprinter was configured with a checkweigher, centralized tape machine, two sortation diverts, and extendable conveyor so packages can travel directly into the truck for ease of loading.

Pack & Ship Cold Chain Operation w/ Auto Sealer

For this cold chain fulfillment system, the Sprinter was configured from the pack stations inside a cooler, to checkweigh for ice detection, Q/A, automatic sealer and then sortation by carrier.

E-Comm: Centralized Void Fill & Carton Sealer

For this direct-to-consumer e-commerce client, Sprinter was configured with centralized void fill, semi-automatic taper and single-sided sortation due to space constraints near the dock doors.

Intelligent Warehouse Control System (WCS) Software

StreamTech bundles our operational and maintenance know-how in the onboard software app that comes on the included Windows Pro 64-bit SSD PC, with rich functionality that supports troubleshooting and enhances uptime. The intelligent warehouse control (WCS) software easily integrates with rules-based multi-carrier systems or direct carrier interfaces.

- Extensive troubleshooting built-in to the system

- Smart filtering of label files

- Expandable for growing customers

- Rich scan, production, and maintenance statistics with configurable retention

- Server-based thin client solutions are available

- Backup UPS included protecting PC and SQL database

- Multi-level security, multi-user login

A Material Handling Control System Platform

The Sprinter™ print and apply labeling system is an excellent first step into automating end-of-line fulfillment processes and is easily expandable to grow with your business. It can also serve as the central control system for other integrated warehouse automation systems.

- Add diverts, merges, etc.

- Open, standard Allen Bradley PLC architecture

- All devices are IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low-cost system control of reseller conveyor equipment

- EWON remote support router included (eliminates the need to go through VPN)

Product Specifications

- Includes: PC, Software, PLC Controls, Conveyor, Scale, Scanners, Backup UPS

- Throughput: Up to 1,080 cartons per hour, based on and limited by the host response

- Std. Box Sizes 9 x 6 x 1 in up to 27 x 20 x 20 in

- Box height variation: 14 in standard, 22 in optional

- Overall System Size – 10 ft long standard

- Electrical – 120VAC, single phase 60 Hz, 6 Amps

- Pneumatic requirements – None

- Meets UL, NTEP, Measurement Canada

System Options

- Belted zones for extra small and non-flat items

- Automated Packslip: Thermal or Plain Paper

- Flat, Polybag, and Mailer capability

- Dimensioner / Dimweight sensing

- Optional Widths and Zone Lengths

- Downstream Sortation

What our customers say

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

How does rate shopping and manifesting work with the Sprinter?

The Sprinter integrates with your WMS and multi-carrier platforms to automatically compare shipping rates in real time based on package weight, dimensions, and destination. It selects the optimal carrier and service level, generates the label, and applies it—all in a single, seamless motion.

Can Sprinter integrate with my existing software systems?

Yes. The Sprinter connects through StreamTech’s WCS, which integrates with most WMS, ERP, and multi-carrier platforms like ShipStation, NetSuite, SAP, and ProShip. We support direct database connections, API integrations, and batch exports for flexible deployment.

Who is the Sprinter best suited for?

Sprinter is ideal for fulfillment operations processing between 500 and 7,000 orders per day. It’s especially valuable for businesses ready to move beyond manual packing and shipping, but not yet at the scale of needing full custom automation.

What is the throughput of the Sprinter system?

The Sprinter can process approximately 600 to 1,000 cartons per hour, depending on package size and system layout. It’s engineered to handle peak periods efficiently while maintaining high label accuracy and uptime.

Most Sprinter print and apply labeling systems are fully installed and operational within 3 to 5 days. Because it’s pre-engineered, the setup is faster and smoother than traditional automation projects—minimizing downtime and getting you to ROI sooner.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields