Conveyor Systems

We do the hard stuff that makes conveyors look easy

Built to Move

Expert Conveyor Integration for Modern Fulfillment

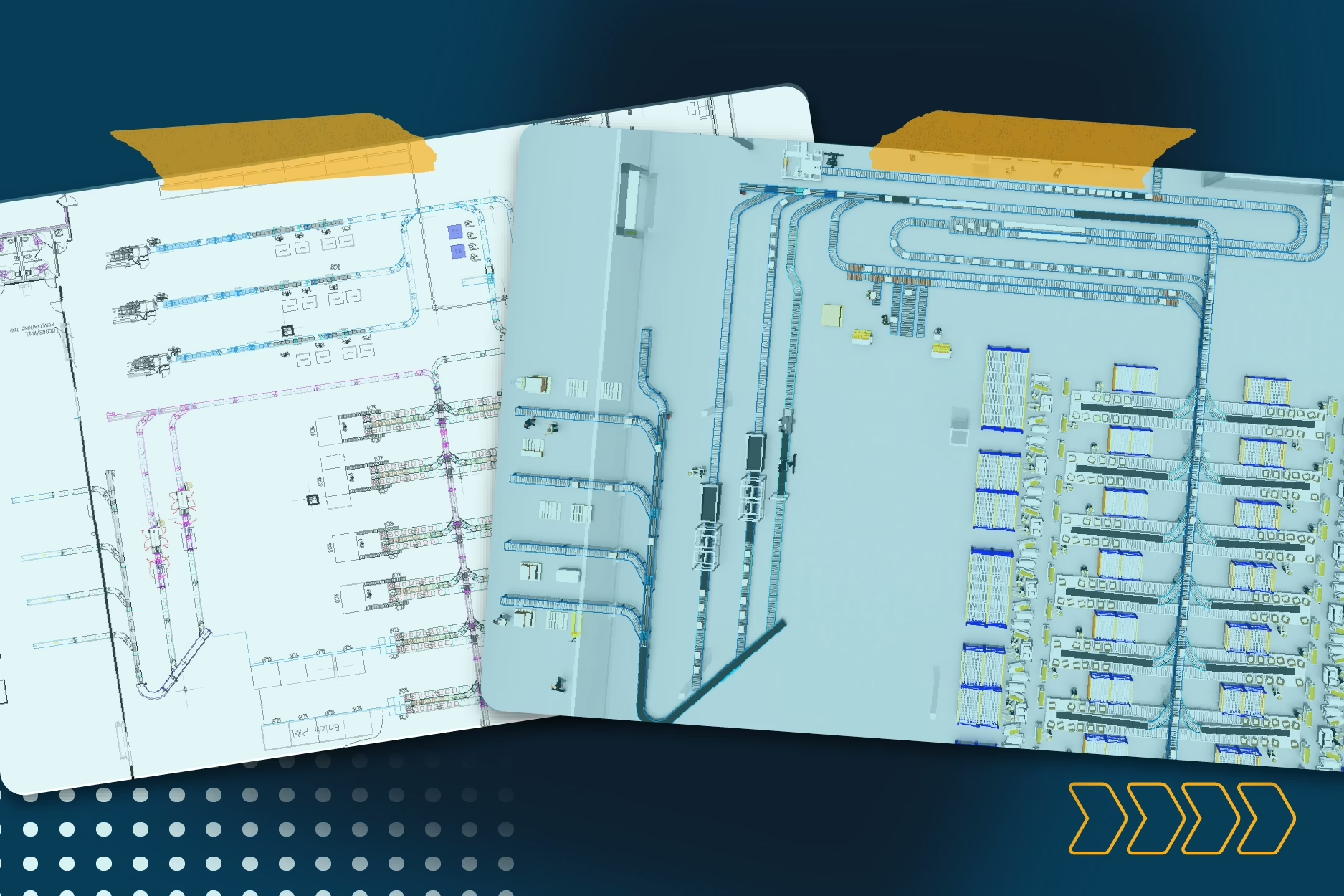

From simple transportation lines to complex multi-zone systems, conveyor solutions play a critical role in fulfillment speed, accuracy, and efficiency. As an experienced MHS conveyor integrator, we design, install and optimize systems that meet the demands of today’s fast-paced operations—delivering reliable, low-maintenance performance that grows with your business.

Intelligent Conveyor Design & Control

At StreamTech, we don’t believe in one-size-fits-all conveyor designs. Whether you’re moving long boxes, small parcels, bags, flats, or totes, our systems are engineered for precise gapping, smooth transportation, and seamless movement around curves, inclines, and zone transfers. Every conveyor is carefully controlled with PLC ladder logic and tightly integrated with our WCS software—ensuring your product flows exactly where it needs to, when it needs to.

Merges – Streamline multiple conveyor lines into a single, efficient flow with precise control and minimal product disruption.

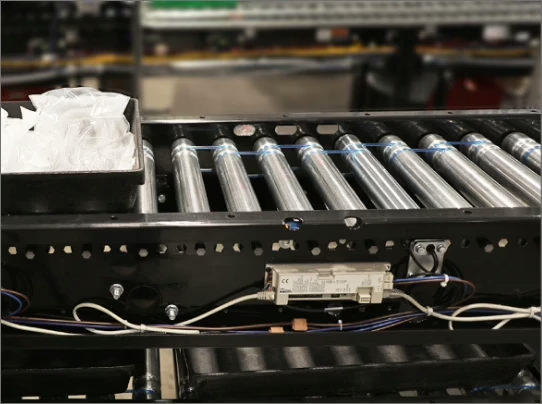

Accumulation – Buffer product with zero-pressure accumulation zones to prevent jams and maintain smooth, sequenced flow.

Transportation Belt – Move product quickly and efficiently across longer distances with minimal noise and consistent speed control.

Zone Transfers – Maintain continuous, balanced product flow between conveyor zones using PLC-controlled handoffs.

Inclines & Declines – Safely move product between elevation changes with controlled speed and smooth transitions.

Curves – Navigate tight turns with engineered curve designs that preserve gapping and product orientation.

Parcel Sortation

StreamTech has extensive experience in implementing complex sortation installations for a wide variety of clients. Utilizing a combination of both our sortation hardware and our WCS software, we provide cost-effective, user-configurable sortation systems for a broad range of applications. With deep expertise in material handling best practices, StreamTech designs custom solutions tailored to your operational goals and the specific types of products you handle—ensuring your system performs efficiently and accurately in your unique environment.

Sprinter™ Pre-Engineered Print & Apply Shipping System

An all-in-one scan, weigh, dimension, print and apply shipping system.

The Sprinter™ can process approximately 600 to 1,000 cartons per hour, uses standard components, an accumulation conveyor for accommodating manifest response time, and is pre-engineered for fast installation. It is an excellent first step into automation.

Intelligently Controlled

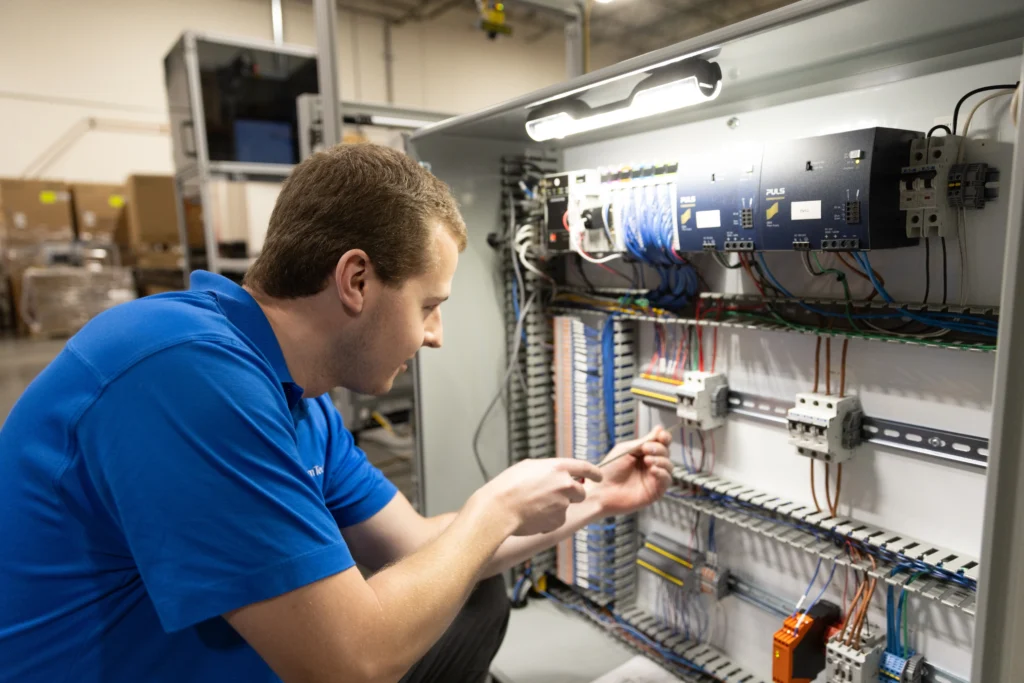

PLC Controls

StreamTech designs, builds and installs the control panel to match up with our WCS software and integrated automation hardware. Machine control is provided by an Allen Bradley CompactLogix PLC, which is easily expandable to manage additional automation. Its open architecture allows end users to support and maintain the system independently if desired.

- Add diverters, merges, etc.

- All devices IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low-cost system control of reseller conveyor equipment

- EWON remote support router included (no VPN needed)

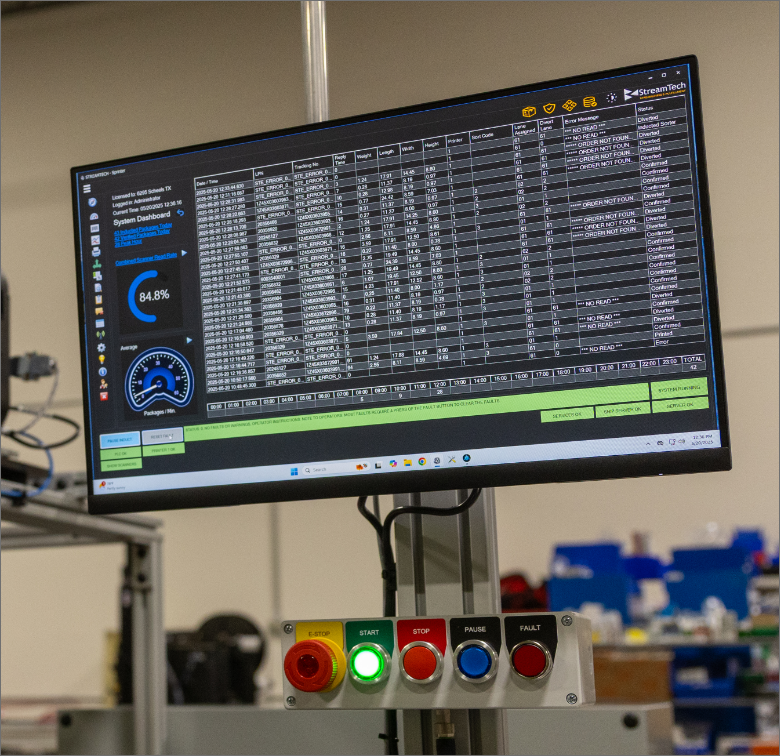

WCS Software

Conveyors don’t operate in isolation—they’re part of a larger automation ecosystem. Our systems integrate with warehouse control software to manage routing, optimize flow, and deliver real-time data.

This tight integration ensures your conveyors work in harmony with upstream and downstream technologies, providing the flexibility, visibility, and efficiency your fulfillment operation demands.

Frequently Asked Questions

If you have any further questions, please don’t hesitate to contact our customer support team for assistance.

MDR conveyors offer energy efficiency and quieter operation. Because the rollers only activate when needed, they reduce overall power consumption, limit wear and tear, and help create a smoother, more controlled flow of goods.

Most systems we integrate feature a low-maintenance design with fewer moving parts, durable bearings, and built-in tracking. That means less downtime and fewer service calls for your operation over the life of the system.

Installation is typically fast and efficient. Many of the systems we work with are modular, pre-wired, and designed for simplified setup—helping you minimize disruption and get up and running quickly.

Yes. The conveyors we source are built for longevity and backed by reliable manufacturer support. They’re designed to scale with your operation, making them a smart long-term investment in your fulfillment infrastructure.

Start by checking the photo eyes—misalignment is a common cause of these issues. Also make sure the system isn’t paused and no E-stop buttons are tripped. We can help walk you through basic troubleshooting or coordinate with the manufacturer if needed.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields