Estimated reading time: 7 minutes

Print On-Demand products don’t behave like cartons—and automation systems that overlook them will end up with material handling problems. At StreamTech, we design fulfillment automation that accounts for the realities of these “non-standard” products – from day one.

From flat mailers that slip beneath sensors to canvases that extend beyond traditional conveyor widths, our focus is on building systems that keep every product moving smoothly and accurately, to deliver the ROI you are looking for.

Why Flat Items Can’t Be an Afterthought

Our first example for printed goods – flat items (posters, envelopes, prints, and photographs). These products look simple but create more problems than many operators expect.

Challenges:

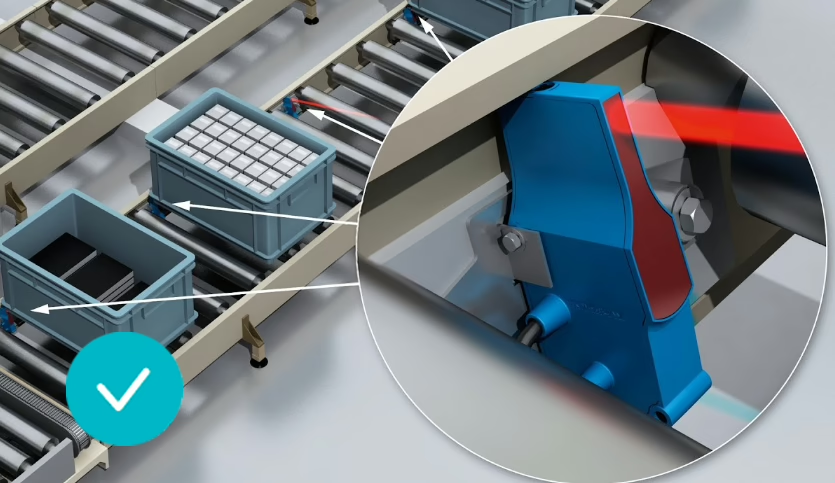

- Flats ride beneath traditional photoeye sensors built into conveyor rails, causing missed detections.

- Inline scales need to be sensitive enough to register such lightweight products.

- No vertical dimension exists to capture – so a dimensioner may not be needed, if you already know your L x W.

- Flats will need a top scanner for the LPN. But watch out because if the shipping label covers the LPN, downstream scan verification is lost.

- For completely flat mailers without any padding, it is important to specify the correct label applicator that has some pressure sensitivity to prevent aggressive tamping directly on the equipment.

Solutions to consider:

- Between-the-roller mounted photoeyes that are either set at an angle, or positioned to scan vertically to see any item passing through.

- Specialized lightweight scales ensure flats are detected and weighed reliably.

- Overhead LPN scanning before label application, with flats aligned consistently and labeler positioned to avoid covering the LPN.

- Slim, sturdy mailers that prevent creasing.

- Workflow design that batches similar-size items to keep processes efficient.

The takeaway: without specialized detection, weighing, and scanning, flats become a weak link. With the right design, they flow as smoothly as cartons.

Bonus: Picking Flats & Feeders

One benefit that works for flat items that works as a positive – they can sometimes be picked in batches and fed using either a pick-and-place robot, or feeder. This allows the picking process to be more efficient, allowing operators to run large batches of orders without having to manually induct them one at a time. Be careful though with feeding items of varying thickness. Consistency is key with feeders.

Long, Heavy Prints and the Limits of Single Scales

Oversized prints and canvases are fragile, irregular, and often larger than what standard conveyors and scales can handle.

Key engineering considerations:

- Sometimes large canvases may be too big for traditional accumulation conveyor widths. We can work around this by designing the conveyor to be rollers-high, without rails so that if necessary, oversized canvases can hang over the edge (some).

- Light curtain dimensioners capture length and width when overhead dimensioners can’t span the full field of view.

- Multi-scale setups—either in series for length or side-by-side as multi-belt scales—ensure accurate weight capture across the product’s footprint.

- Packaging with reinforced corners and cushioning reduces risk in transit, while carrier selection should favor those experienced with large-format items.

- Creative scanning may be required if the LPNs are inside the box. We can develop a system to label the flap with the box open if necessary.

The takeaway: while traditional e-commerce may see oversized products as a very small share of the order profile, print on demand companies may see canvases as their primary order volume. Meaning we have to consider proper weighing, dimensioning, and packaging to design the system around their order profile.

The Unique Challenge of Blankets and Textiles

Textiles such as custom blankets are among the fastest-growing print on-demand items—and among the hardest to automate. Their irregular shapes and bulk create multiple hurdles:

- Shrink wrapping: must secure the product without damaging it.

- Packslip scanning: documents placed inside wrapping much remain visible and scannable.

- Label application: uneven surfaces require adaptable print-and-apply systems.

Integrated workflows that handle wrapping, scanning, and labeling together prevent textiles from slowing down an otherwise smooth operation.

Bagged Items: Verification Disappears

Opaque baggers are efficient for certain SKUs but create a verification gap.

Here’s how it typically plays out:

- The LPN is scanned upstream.

- A shipping label is created an applied.

- Once sealed inside the opaque bag, the product can no longer be re-verified downstream—the identifier is hidden beneath the bag.

Automation must account for this by ensuring scanning, label placement, and verification happen before sealing. Otherwise, the process loses visibility and traceability at a critical point. RF labels can be a possible solution as well, although they present their own challenges to dial in the scanning range and shield around the scan area.

Designing Automation for Print On-Demand

Custom print items—flats, oversized canvases, textiles, and bagged goods—aren’t “exceptions” to path later. They have to be part of system design from the start.

Ignoring them leads to costly mistakes:

- Missed scans and misapplied labels

- Misclassified weights and shipping errors

- Manual rework that slows throughput

- Customer dissatisfaction and rising costs

Each challenge has a proven automation fix—scan tunnels for thin mailers, custom conveyor design for large overhand products, integrated workflows for textiles, and verification logic for bagged items. With these details engineered upfront, fulfillment stays scalable, efficient, and competitive.

Real Results: How Pic the Gift Scales Custom Print

Pic The Gift streamlined fulfillment for custom products like blankets by automating scanning, weighing, labeling, and verification. The result? Faster throughput, lower labor needs, and smooth peak-season performance.

Ready to Rethink Print On-Demand Fulfillment?

Automation doesn’t succeed by covering 90% of SKUs and leaving the rest for manual handling. Success means building workflows that account for the details of your package profiles.

Whether you ship envelopes by the thousand, oversized canvases by the pallet, or blankets by the day, a system built with these realities in mind ensures accuracy, efficiency, and growth.

Because in custom print on-demand fulfillment, the details aren’t minor—they’re the difference between meeting expectations and falling behind.