Estimated reading time: 4 minutes

Why is a package inspection system important? In fulfillment automation, the integrity of the box is critical to the success of the automation, particularly with regard to dimensioning, labeling, conveyance, and sortation. We look for ways to add value to both our existing customers as well as new ones, and our controls and software engineers regularly explore new technology to solve problems.

Poor box integrity causes a variety of problems for the rest of the fulfillment automation process, so we have invested in research and technologies that can allow us to catch problems early.

What Are The Implications Of Poor Box Integrity?

Let’s look at an application such as our Sprinter™ dimension, weigh, scan, print, and apply labeling systems (also referred to as a SLAM system). These are integrated downstream from either a case erector, taper, or some other box right-sizing system (or a person).

To proceed successfully through these processes, the box must be properly closed. Poorly taped or glued boxes create issues with print-apply and dimensioning systems – for example, label adhesion, and incorrect dimensions. Boxes were getting labeled and sorted correctly, but (if not caught by operators) the contents of the box were being spilled out somewhere during shipment, leaving customers obviously unhappy.

Some Other Implications Of Poorly Constructed Boxes Could Include:

- Loss of contents during conveyance, sortation, or shipment

- Wasted time chasing down inaccuracies

- Incorrect label application

- Damage to the order contents or the labeler’s tamp during application

- Bad dimension data due to interference with major/minor flaps (incorrect box height), which would cause incorrect multi-carrier rate shopping, costing you money

In order to catch these errors before they become such a big problem, we employ specialized sensors which integrate with the Sprinter’s WCS software, to detect these problems and prevent them from costing you money. Let’s explore how it works.

How Does This Technology Work, And How Do We Use It Within The Automation?

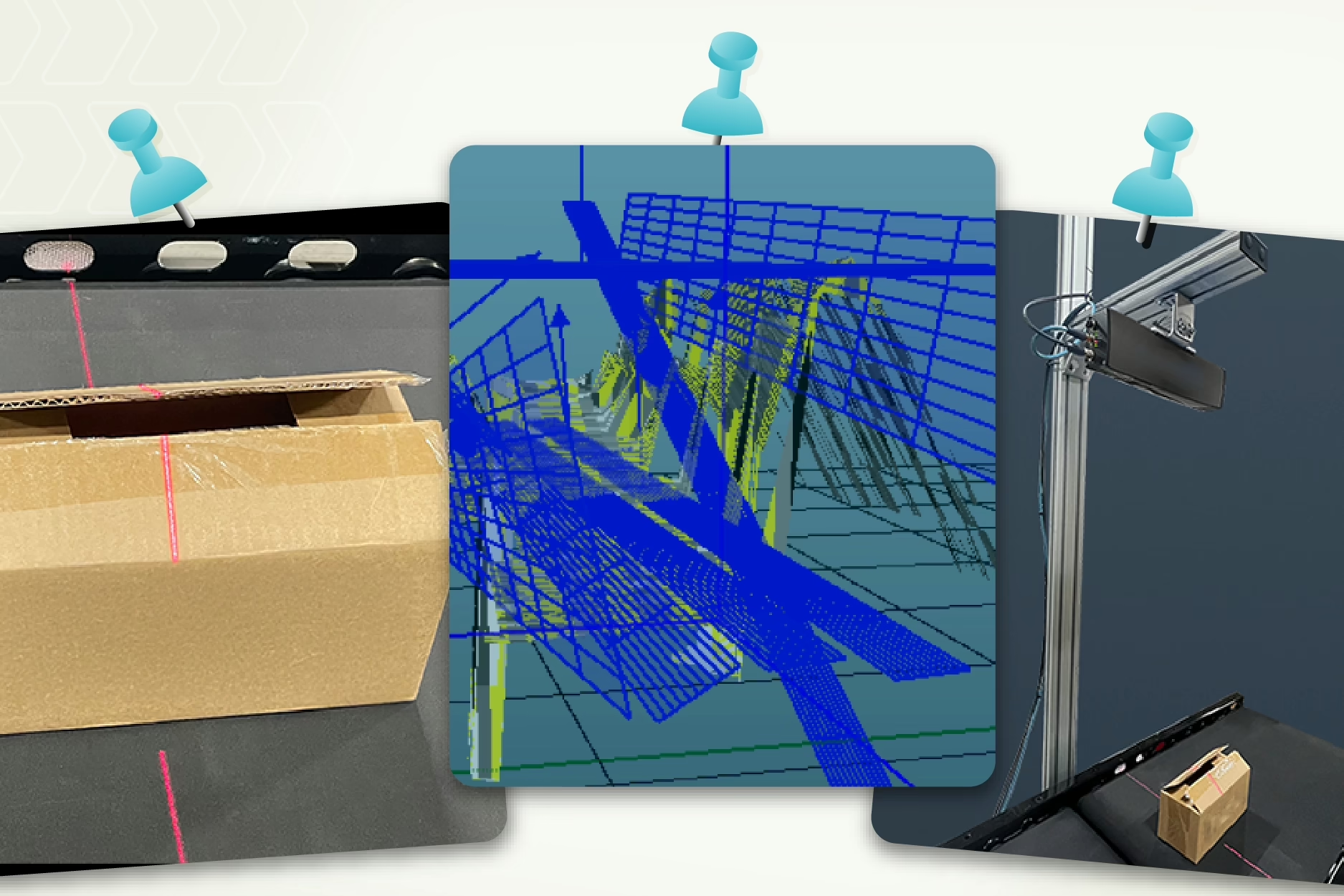

StreamTech uses LiDAR, projecting a laser over the surface of the object, and reading it back, to identify whether it is flat, open or closed. In this implementation, if the object is flat, the system will deliver a “PASS” reading, and allow the package to continue. If it detects an uneven surface that does not meet the required parameters, it will deliver a “FAIL” result, and proceed with the necessary corrective actions.

After a package passes through the package inspection system, this data is transmitted to our PLC, which can:

- Flag improperly sealed packages prior to the print-apply shipping system, and send a signal to the printer to inhibit the label from applying.

- Inhibit the dimensioner to prevent inaccurate heights.

- Alarm a status light and stop them in their place on the conveyor.

- Sort them to the “jackpot” lane.

Additionally, this system could be a great way to gather data on your carton sealing or lidding equipment and catch maintenance problems early before they become too costly. Data can be fed back into our Warehouse Control System (WCS) software, to report on and log which orders, which equipment, and/or on which lane these errors are most frequently occurring.

This laser-based detection system is not necessary for every application but can be a very helpful tool in mitigating issues that can arise from poorly constructed or sealed boxes. Automation is a balance, and incorporating the right technology can save you time, and money and make or break the relationship you have with your customer. Adding intelligent components such as this can be most effective when the PLC hardware and WCS software communicate well with each other. Learn about our WCS software, and how it can act as the central hub for your warehouse automation.

StreamTech specializes in fulfillment automation, from picking, pack slip automation, dimension, weigh, scan, labeling sortation, and more. If you are interested in finding ways to improve your warehouse operation, fill out the contact form below and we’ll set up a meeting to discuss your needs.