Automation Empowers Holland Group To Ship Live Plants Globally During Peak Seasons

Holland Group

Holland Group, a fifth-gen family business, ships live plants through six online brands and faces extreme seasonal surges with up to 80,000 preorders and 12k new weekly orders. With StreamTech’s Sprinter™, they now process 7k orders per day with less than half the labor, improving accuracy and freeing staff to support other parts of the operation.

Overview

Holland Group is a family-owned and operated company that has been in operation for over 5 generations of farmers, growing and selling plants. In 2004 the company decided to be an early adopter of eCommerce, and launched a storefront to sell their bulbs to customers online. Since then, the company now has 6 separate brands, with over 1,300 different SKUs of plants.

With both a Spring shipping season and a Fall shipping season, their warehouse operations ramp up and down dramatically to meet demand – a much more drastic ramp than most e-comm operations experience. This makes the Holland Bulb fulfillment process unique. In one season, they may begin shipping with over 80,000 preorders to get shipped before the season ends, while simultaneously receiving 12,000 new orders every week – this puts a huge strain on the operations.

The Automation Solution

This is why Holland Group turned to fulfillment automation to help scale up to match demand – a common problem that many warehouse operators have, but which is exacerbated for Holland Group by the limits of planting season.

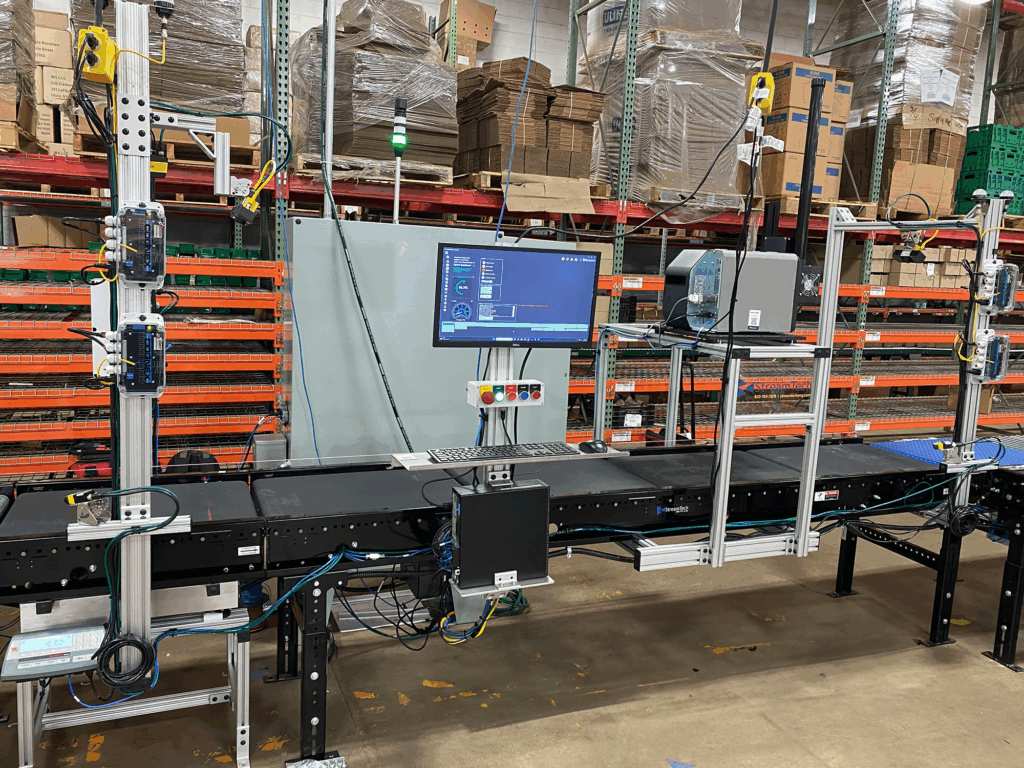

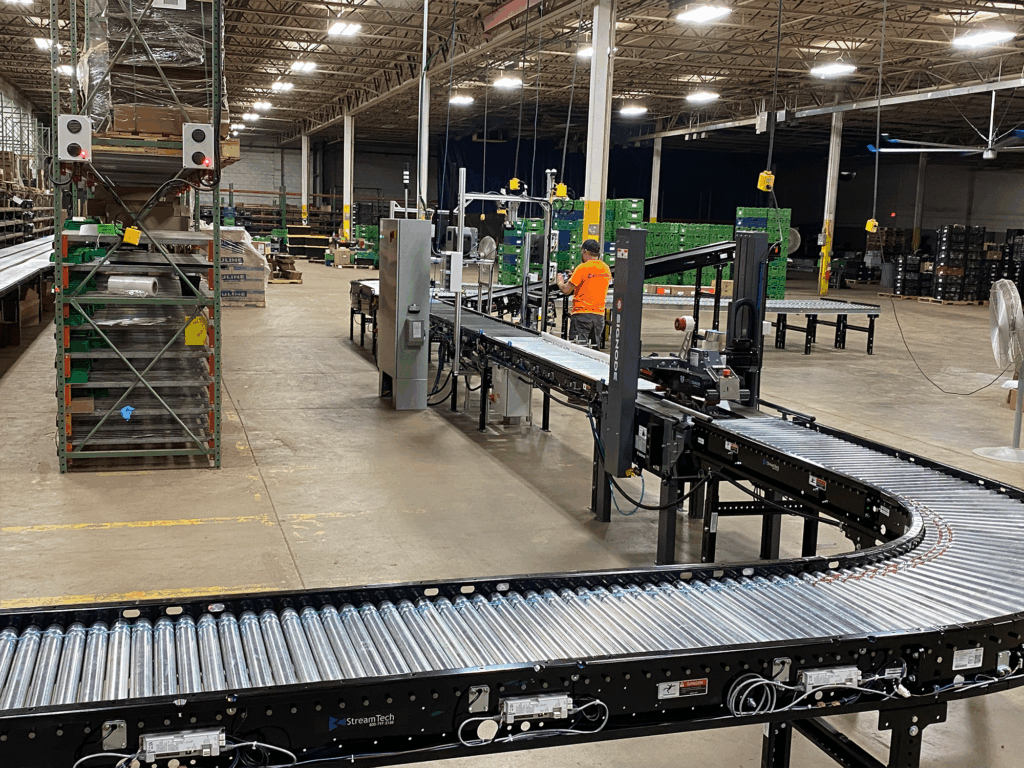

Holland Group’s orders from all six brands travel down a central conveyor, where they flow through the following process:

- Pick: orders are picked along a central conveyor using a pick-to-light system, directly into the shipping carton.

- Pack: the packing slip is placed in the box, and at the end of the pick line, an operator adds a brand sticker, product instructions, and void fill.

- Ship (Dim, Weigh, Manifest, Label): once orders are complete, each box will be scanned, weighed, dimensioned, and manifested for shipment using their TMS software, which also handles rate shopping by carrier and service level. This process happens within a fraction of a second – then we automatically print and apply a carrier label to each box.

- Sort: the system then automatically diverts packages to separate lanes that are devoted to different carriers, then palletized.

Holland Bulb can ship over 20k orders per week, however, each week may provide a net gain of over 12k orders/week, which means they have to crank up their operation to get all the orders out the door to keep up with demand throughout the season. Before implementing StreamTech’s Sprinter™ system, Holland Group relied on manual operators at 5 separate shipping stations, each with its label printer, scale, taper, and void fill machines.

These team members could get through about 5,000 orders daily, with 7 dedicated staff. Not only did this process require a lot of labor, but it also required them to stack pallets of picked orders, transport them to the shipping stations, process those orders, and then re-stack the pallets by carrier and transport them again.

Once the StreamTech Sprinter™ was implemented, Holland Bulb was able to process over 7,000 orders a day, with only 3 dedicated shipping staff members. Each of the other staff members was able to be re-allocated to other areas of the operation. The company has also recognized an increase in order accuracy.

“Implementing new technologies can certainly increase your capabilities but it still takes a great team. I am surrounded by a great team both in our office and in our warehouse. I believe that’s one of the main reasons we’ve been successful. StreamTech also employs great individuals.”

Andrew Mulder – Warehouse Manager, Holland Group

Holland Group continues to explore new automation solutions as the company grows. StreamTech is thankful to be a small piece of Holland Group’s success, and look forward to seeing what the future holds. If you are considering fulfillment automation, please fill out the form below.

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields