Estimated reading time: 11 minutes

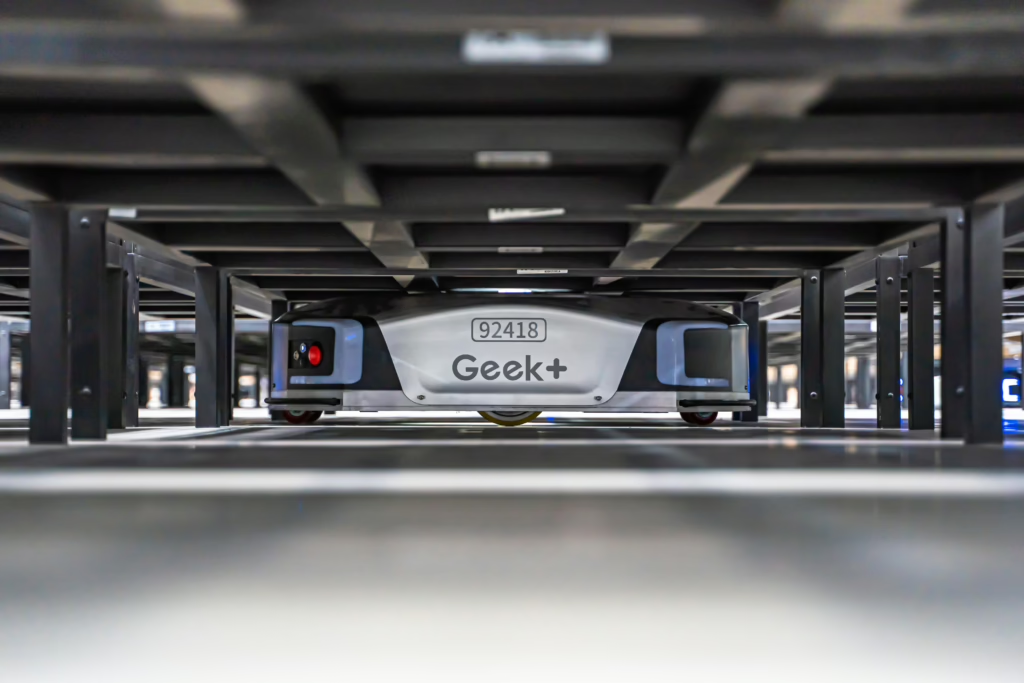

Over the past few years, goods-to-person (G2P) robotics have revolutionized warehouse fulfillment by significantly enhancing picking speed, accuracy, and efficiency. These advanced robots have transformed traditional workflows, reducing the need for manual labor and minimizing human error.

Related Links

- 3PL Fulfillment Automation: Transforming Processes for Operational Efficiency

- 3PL Fulfillment Automation

However, these technologies are not standalone solutions to the entire warehouse fulfillment process, and are not intended to replace traditional warehouse automation systems. Rather, in order to realize the full potential of automated warehouse operations, G2P robots must be seamlessly integrated with conventional technologies such as conveyors, end of line print and apply labeling systems, and in some cases, automated packaging equipment. This comprehensive integration ensures a streamlined, end-to-end fulfillment process that maximizes efficiency, reduces costs, and improves overall service quality.

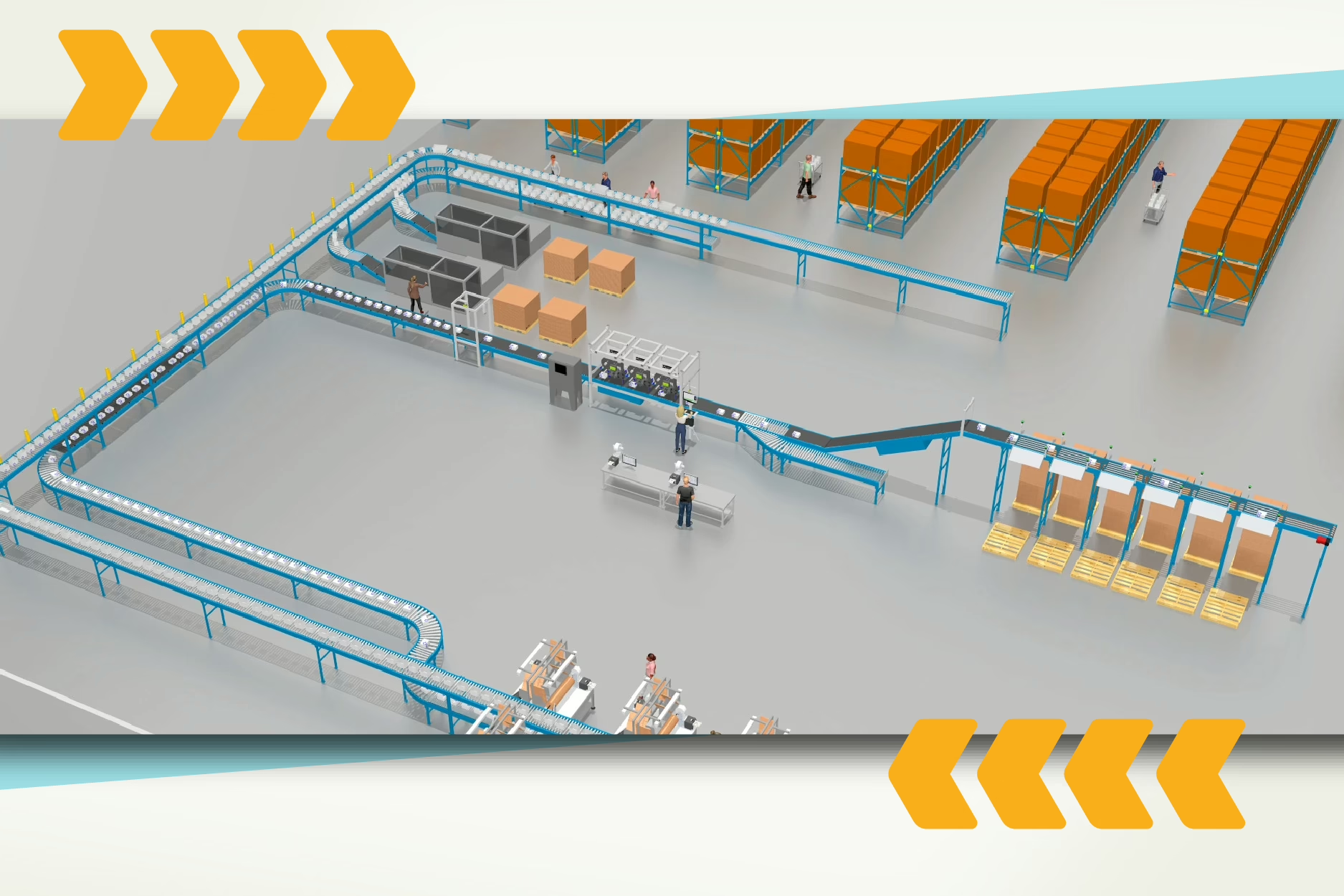

Material Flow In An Integrated Warehouse

The material flow in a modern warehouse equipped with Goods-to-Person (G2P) robots and integrated technologies is a seamless and highly efficient process. Here’s a breakdown of each step involved, highlighting how different technologies contribute to a streamlined operation.

Picking Process

G2P robots efficiently bring items to designated picking stations where human workers or automated systems can quickly access the products needed for each order. This minimizes walking distances and waiting times, significantly speeding up the picking process.

Transportation To Packing Stations

Once items are picked, conveyors play a crucial role in transporting these items to the next stage — packing. Conveyors are configured to handle various types of goods delicately and efficiently, ensuring a continuous flow from picking to packing without manual intervention, thereby reducing bottlenecks and errors.

Packaging

At the packing stations, automated packaging equipment takes over by creating the appropriate box or bag tailored to each specific order. This machinery adjusts to the size and fragility of items, optimizing material usage and ensuring that products are securely packaged for transit.

Scanning, Weighing, And Dimensioning

After packaging, the next step involves scanning, weighing, and measuring the dimensions of each package. These details are crucial for inventory tracking and quality control. The collected data (package ID, weight, dimensions) is then sent to Transportation Management System (TMS) software, which manifests the correct shipping label based on the package’s destination, weight, and shipping requirements.

Labeling

These systems automatically print and apply shipping labels to the packages as they move along the conveyor. This automation ensures that the labeling process is not only fast but also accurate, reducing the chances of human error and ensuring that each package is ready for dispatch without delays.

Sortation

The final step in the material flow process involves sortation. This system sorts the labeled packages according to customer rules, which may include product type, shipping destination, carrier, or service level. Sophisticated parcel sortation systems can handle high volumes of packages and sort them accurately at high speeds, ensuring that packages are routed correctly to their final destinations.

Integration Examples With G2P Robots

In modern warehouse operations, Goods-to-Person (G2P) robots play a crucial role in enhancing efficiency and streamlining processes. This section explores practical examples of G2P robots integrated with other technologies within different warehouse stages. Through these real-world scenarios, we’ll see how G2P robots effectively reduce manual labor and improve operational workflows from receiving to shipping.

Example 1: eCommerce Order Fulfillment

Imagine a bustling online retail company that specializes in a wide range of consumer electronics—from the latest smartphones to high-end laptops. To manage their massive inventory and fulfill orders quickly and accurately, they turned to an advanced warehouse automation solution.

- Picking: The first step in the order fulfillment process involves state-of-the-art Goods-to-Person (G2P) robots. These robots navigate through storage racking, picking up racks as necessary and bringing them to the picking stations. Each time a rack is presented to an operator, multiple pick operations take place. This eliminates the time spent walking and searching for specific products, allowing operators to focus more on accuracy and speed, and less on the physical retrieval of items.

- Conveyance: Once items are picked, they can be placed in a plastic tote which represents the order, and transported on takeaway conveyor. This tote will convey to the packaging equipment, or a packout station, to be placed in the final parcel.

- Packing: Once the items are picked, they are swiftly conveyed to the packing stations. Here, automated packaging equipment takes over. This machinery is meticulously designed to handle a variety of product sizes and types, from delicate electronic components to bulky home appliances. Each item is securely packaged according to its specifications, ensuring that it is well-protected during transit and arrives in perfect condition to the customer.

- Weighing, Dimensioning, and Labeling: As the packed items move along the conveyor, they enter a critical stage where they are weighed, and their dimensions are recorded. Specialized scales and dimensioning tools collect all necessary data to comply with shipping standards and help optimize space in delivery vehicles. Immediately afterward, print and apply systems efficiently add shipping labels to each package. These labels contain all essential tracking information and delivery details, ensuring smooth and traceable transit.

- Sorting And Shipping: In the final step, the labeled packages are conveyed to sorting areas. Here, they are organized meticulously based on various criteria such as the destination, carrier, or service level required. This sorting process is crucial for managing the logistics of shipping vast numbers of orders daily. Once sorted, the packages are moved to the shipping areas, where they are ready for dispatch to eagerly waiting customers.

Example 2: Receiving Systems For Store Replenishment

Let’s envision a sports equipment retailer that specializes in everything from soccer balls and tennis rackets to high-end bicycles and fitness gear. Given the diverse range of products and the potential for wear and damage during transit or use, handling returns efficiently is crucial for maintaining customer trust and operational efficiency. Here’s how they could leverage StreamTech’s automated warehouse technologies to manage inventory effectively:

- Receiving Goods: As soon as items arrive at the warehouse, they are placed on receiving conveyors. This initial step segregates returned goods from new inventory right from the start. This separation simplifies the processing workflow, ensuring that returned items are quickly moved to dedicated inspection stations without interfering with the flow of new stock.

- Labeling: Inventory items are scanned and labeled based on their designated store locations before sortation. Upon arrival, each item is scanned to capture relevant information such as SKU, quantity, and destination store. This data is used to generate labels indicating the specific store each item belongs to. The labeled items are then fed into the sortation system, which directs them to the appropriate location for distribution to their respective store. This process ensures accurate sorting and efficient handling of inventory across multiple store locations

- Sorting By Store: As items arrive at the dock door, they are placed on the conveyor system, which moves them through various checkpoints where they are scanned and identified. The sortation system then directs each item to the appropriate sort location based on the retail store it belongs with. This is done through communication with the WMS (Warehouse Management System), where inventory levels are kept. This automated process ensures that inventory is quickly and accurately sorted, reducing manual handling and expediting stocking and restocking tasks, ultimately enhancing operational efficiency and inventory management.

- Robotic Put Away To Picking: In the 3D render shown above, the sorted items are headed to pallet positions, to be loaded and shipped directly to store. But if these items are being sorted for fulfillment, they could be picked up by robots and distributed into the G2P system to be picked again later if necessary.

Additional Technological Integration

Sensors: Tracking And Monitoring

In a modern automated warehouse, sensors track and monitor the movement of goods, robots, conveyors, and packaging equipment in real time. This continuous monitoring helps maintain the flow of operations and ensures that all components of the warehouse system are functioning correctly.

Quality Control

These devices scrutinize each package as it moves through the system, detecting any issues—such as misalignments or damage—that require correction, thus maintaining high standards throughout the process.

Conveyor, Labeling, And Sortation

- Integration With Warehouse Management Systems (WMS): This integration ensures that shipping labels are printed with the correct order information and destination details. This helps maintain order accuracy and streamlines the dispatch process.

- Conveyor Integration: Labeling systems are strategically positioned along the conveyors. As packages move through, labels are applied seamlessly, which optimizes the workflow and reduces bottlenecks.

- Error Handling: The integrated systems are also equipped to detect and handle errors in labeling. This capability is essential for maintaining accuracy, minimizing the need for rework, and keeping the operation running smoothly.

- Automated Sorters: Once labeled, packages are handed off to automated sorters that organize them based on their destination. This sorting process is key to improving shipping efficiency and ensuring timely deliveries.

Automated Packaging Equipment

- Custom Packaging: The automated packaging equipment adjusts the size and type of packaging based on the item dimensions and specific order requirements. This customization not only ensures the safety of the items during transit but also optimizes material use.

- Integration With Conveyors: As items arrive via conveyors, they are immediately packaged and then moved to labeling stations. This seamless movement is crucial for maintaining a steady flow through the packaging phase.

Benefits Of Comprehensive Integration

The integration of automated systems in warehouse operations offers a range of compelling benefits that streamline processes and enhance overall performance. Here’s how these integrations can transform the landscape of logistics and fulfillment:

Increased Efficiency

Automated systems such as Goods-to-Person (G2P) robots, automated packaging, and advanced sorting mechanisms significantly streamline critical warehouse operations including picking, packing, labeling, and shipping. By reducing the need for manual intervention, these systems allow operations to flow more smoothly and rapidly, drastically cutting down on cycle times and enhancing throughput.

Enhanced Accuracy

One of the standout benefits of automation is its impact on accuracy. Automated systems minimize human errors in order fulfillment processes, from the initial picking of items to the final shipping stages. This precision is crucial in ensuring that every package is correctly and securely prepared for shipment, significantly reducing the incidence of customer complaints related to incorrect or damaged goods.

Scalability And Flexibility

Automation provides the scalability needed to adjust operations based on fluctuating demand. Automated systems can be programmed to handle different volumes of work, making it easier to ramp up operations during peak times and scale down when necessary. Additionally, these systems offer the flexibility needed to adapt to various warehouse layouts and manage a diverse range of product types, allowing companies to expand their product offerings without compromising operational efficiency.

Cost Reduction

Integrating automated systems can lead to substantial cost savings. By reducing the reliance on manual labor, companies can lower their labor costs. Furthermore, the increase in accuracy and efficiency helps minimize costly errors and reduce waste, saving additional time and resources. Over time, these savings can contribute significantly to overall profitability.

Improved Customer Satisfaction

Faster and more accurate order fulfillment directly contributes to higher customer satisfaction. When customers receive their orders quickly and without issues, their overall satisfaction increases, which is likely to lead to repeat business and positive word-of-mouth. In competitive markets, the ability to consistently meet customer expectations with reliable and efficient service can be a significant differentiator.

Unlocking The Full Potential Of G2P Robotics Through Comprehensive Integration

In conclusion, while G2P robotics have significantly advanced warehouse fulfillment, their true potential is unlocked when integrated with traditional technologies such as conveyors, print and apply labeling systems, and automated packaging equipment. This holistic approach ensures a seamless, efficient, and accurate end-to-end fulfillment process.

To achieve this level of integration, it is crucial to work with a material handling integrator who can expertly bring together all these components, including the necessary software and controls. Such an integrator ensures that the entire system operates cohesively, maximizing efficiency and minimizing disruptions, ultimately delivering superior performance and customer satisfaction.

To explore how StreamTech can help your organization achieve an integrated, intelligent warehouse, contact us today. Our team of experts is ready to provide tailored solutions that meet your specific needs and help you navigate the complexities of modern warehouse automation.