Fine-tuning a fulfillment system requires precise control over the packages as they flow through the process. Alignment or “justification” of cartons to a specific side of the conveyor plays a big role in the accuracy of label placement, sensors, merging/diverting, as well as prevention of bottlenecks. In many cases, alignment often requires the placement of a sorter or a whole section of conveyor devoted to it. Using a sorter for alignment only can be a costly way to accomplish the task, and only uses a small portion of the device’s overall capability.

Common Applications For Package Alignment Include:

- Direct cartons closer toward the sensors to improve barcode reading accuracy

- Position cartons in the correct location beneath a printer applicator

- Guide long boxes around tight conveyor curves and prevent jamming

- Align cartons to the shortest point at diverts, to reduce travel time and increase speed

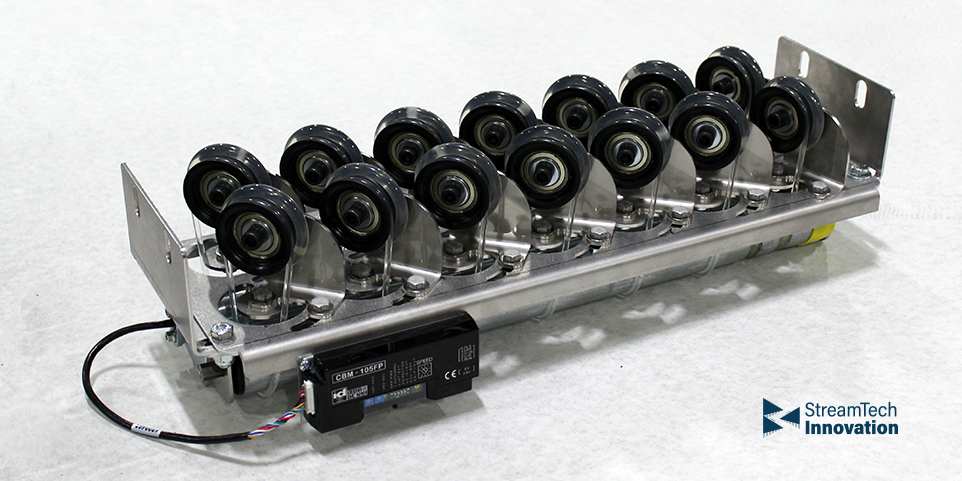

StreamTech saw the need for a compact, easily-retrofitted unit that is devoted to alignment only. Our Drop-In Conveyor Aligner™ (DCA) fills a gap in the market. Lots of skew beds, sorters, and other alignment options have a larger footprint, cost more, cannot be easily retrofitted into existing conveyors, and cannot be adjusted for different angles once installed. We designed our own aligner to solve all of these problems and give our customers a better choice.

StreamTech Drop-In Aligner DCA Features & Benefits:

- Retrofit to existing conveyor installations – just remove two tread rollers and install through channel hex holes. The unit attaches via two height-adjustable bolts on each side, to ensure grip with cartons.

- Strong alignment angle saves floor space versus shallow angled skewed roller systems

- Uses standard conveyor drive cards, plug and play into existing systems

- Each roller is adjustable for harder or softer alignment as desired

- Works with any size conveyor – available in 16 or 22 in. (between frame dimensions), or can be custom ordered to fit

- Reliable and consistent – proven in real-world use for over 8 years of continuous operation!

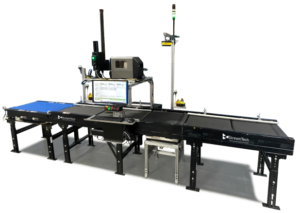

(Example DCA™ Installation)