Print & Apply

Explore Insights, Tools, and Answers

Stay informed with the latest in shipping automation and logistics. From expert articles and upcoming events to product videos and helpful FAQs, our resource center is here to support your operations and keep you ahead of the curve.

-

Print & Apply

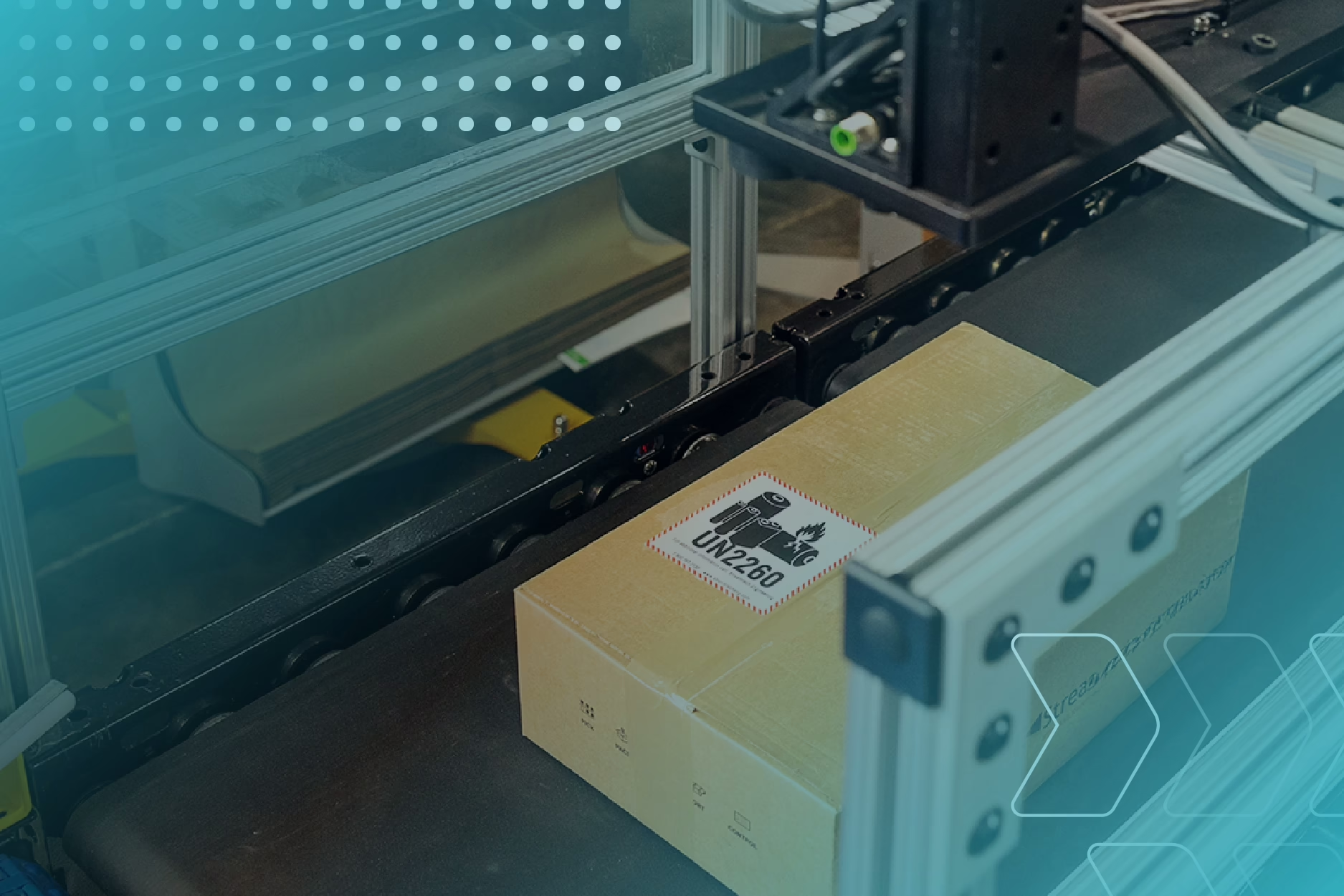

Print & ApplyMastering SLAM: Automating High-Volume Fulfillment

-

Print & Apply

Print & ApplyStreamTech Engineering Helps Guide MHI’s New SLAM System Industry Group

-

Print & Apply

Print & ApplySprinter™ Shipping System: Here’s How It Works

-

Print & Apply

Print & ApplyPiggyback Labeling: Uses & Benefits

-

Print & Apply

Print & ApplyMeet Label Standards With Label Compliance

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields