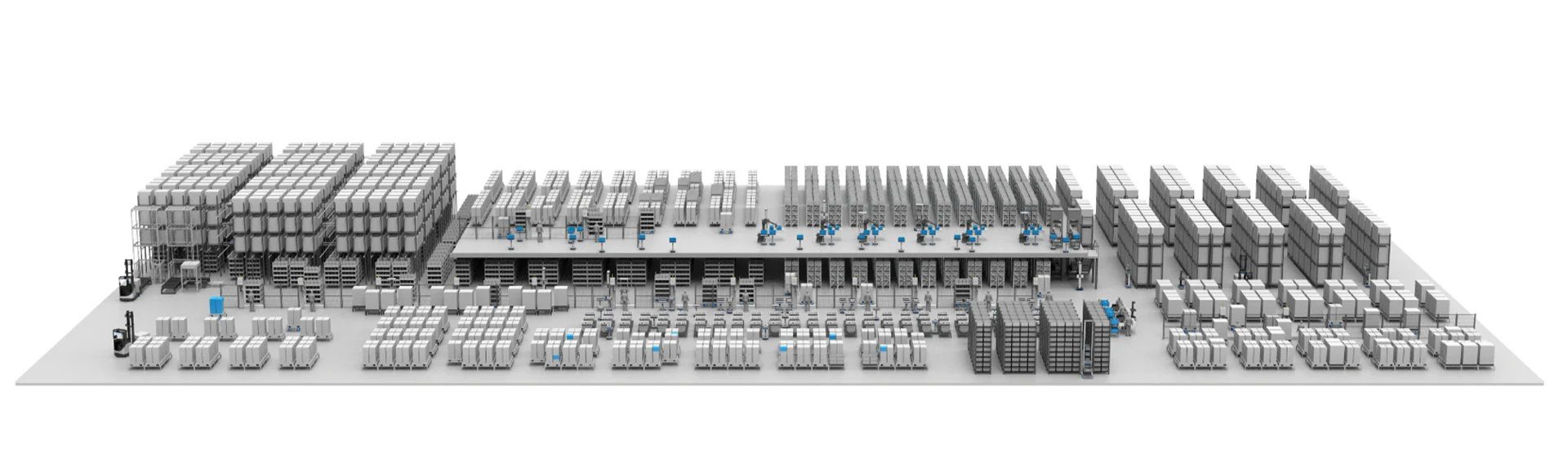

Shelf-To-Person Picking System

Enhance Operations With An Advanced Automated Storage And Retrieval System

Our Geek+ shelf-to-person picking system uses AMR picking robots to move the inventory shelves and pallets directly to the picking station. This reduces the reliance on manual labor, significantly minimizing errors and accelerating the picking process. An automated storage and retrieval system triples or even quadruples efficiency compared to manual picking processes.

The automation provided by this system utilizes AI which allows for continuous operation and improves turnaround times, ultimately leading to higher customer satisfaction through quicker order fulfillment. As a critical component of modern logistics and supply chain management, our automated storage and retrieval system is essential for businesses aiming to stay competitive in today’s fast-paced market.

StreamTech + Geek+

Integrating Cutting-Edge Robotics For Customized Warehouse Solutions

We’re excited to partner with Geek+, a leader in robotics technology, to enhance warehouse operations with our innovative Shelf-to-Person Picking System. Geek+ supplies the advanced robotics that power our systems, while we customize these solutions to fit the specific automation needs of each of our client’s warehouses. This collaboration combines cutting-edge technology with deep industry expertise to deliver an integrated automated storage and retrieval system that boosts efficiency, accuracy, and scalability.

By providing not just implementation but also ongoing support and optimization, StreamTech ensures that clients benefit from continuous advancements in automation technology. Together, StreamTech and Geek+ are redefining warehouse automation, creating solutions that address today’s logistical challenges and pave the way for future growth.

StreamTech + Geek+

Integrating Cutting-Edge Robotics For Customized Warehouse Solutions

We’re excited to partner with Geek+, a leader in robotics technology, to enhance warehouse operations with our innovative Shelf-to-Person Picking System. Geek+ supplies the advanced robotics that power our systems, while we customize these solutions to fit the specific automation needs of each of our client’s warehouses. This collaboration combines cutting-edge technology with deep industry expertise to deliver an integrated automated storage and retrieval system that boosts efficiency, accuracy, and scalability.

By providing not just implementation but also ongoing support and optimization, StreamTech ensures that clients benefit from continuous advancements in automation technology. Together, StreamTech and Geek+ are redefining warehouse automation, creating solutions that address today’s logistical challenges and pave the way for future growth.

Features & Benefits

Discover How Our Shelf-To-Person Picking System Transforms Inventory Management

Order Optimization & Group Picking

This feature streamlines the picking process by grouping orders with similar items, minimizing travel time and increasing efficiency. It ensures that the most logical and shortest routes are followed, speeding up order fulfillment.

Dynamic Wave Picking Process

Dynamic wave picking allows for the flexible grouping of orders into waves, optimizing the picking schedule based on real-time demands and priorities. This method reduces bottlenecks and maximizes throughput during peak operational times.

Heat Mapping & Placement Recommendations

Heat mapping visualizes high-demand areas within the warehouse, guiding the strategic placement of goods to minimize movement. Placement recommendations are generated to further enhance picking efficiency and reduce labor costs.

Inventory Layout Adjustment

This tool enables dynamic adjustment of the warehouse layout based on changing inventory levels and patterns, optimizing space utilization. Regular adjustments ensure that the layout continuously aligns with current operational needs, boosting overall efficiency.

Inventory Management & Intelligent Tally

Advanced inventory management systems track stock levels in real-time, ensuring accuracy and reducing the risk of overstocking or stockouts. Intelligent tally systems provide precise counting and data analysis, enhancing decision-making capabilities.

Robot/Workstation Task Integration

Robot and workstation task integration seamlessly coordinates activities between automated systems and human workers, optimizing workflow. This integration ensures smooth operations and reduces human error by allowing robots and employees to work in harmony.

RFID Technology Integration

RFID technology enhances tracking and management of inventory by providing instant data on the movement and status of items throughout the warehouse. This integration leads to improved accuracy and speed in inventory control processes.

Customization Options

Customization options allow clients to tailor the automated system to fit specific operational requirements and preferences. This flexibility ensures that each solution perfectly aligns with the unique challenges and goals of different warehouse environments.

The Standard For Shelf-To-Person Picking: Geek+ P-800 System

Innovative Automation For Multi-Customer 3PLs

We provided a customized shelf-to-person system for a third-party logistics provider (3PL) that serves over 50 leading online retailers, managing a diverse range of products. Our client required a flexible solution capable of adapting quickly to frequently changing product lines while supporting a multi-customer business model. This system also needed to boost fulfillment efficiency for their retailers, ensuring profitability. In response, we implemented a solution that featured 200 picking robots, resulting in:

- 60% labor reduction.

- 70% floor space savings.

- 3-5 month implementation.

- Minimal fixed infrastructure.

- Centralized supervision.

Innovative Automation For Multi-Customer 3PLs

We provided a customized shelf-to-person system for a third-party logistics provider (3PL) that serves over 50 leading online retailers, managing a diverse range of products. Our client required a flexible solution capable of adapting quickly to frequently changing product lines while supporting a multi-customer business model. This system also needed to boost fulfillment efficiency for their retailers, ensuring profitability. In response, we implemented a solution that featured 200 picking robots, resulting in:

- 60% labor reduction.

- 70% floor space savings.

- 3-5 month implementation.

- Minimal fixed infrastructure.

- Centralized supervision.