Parcel Sortation

Understand your sortation needs, and browse technologies.

What if Your Orders Sorted Themselves?

Solving E-Commerce Order Fulfillment Challenges with Sortation

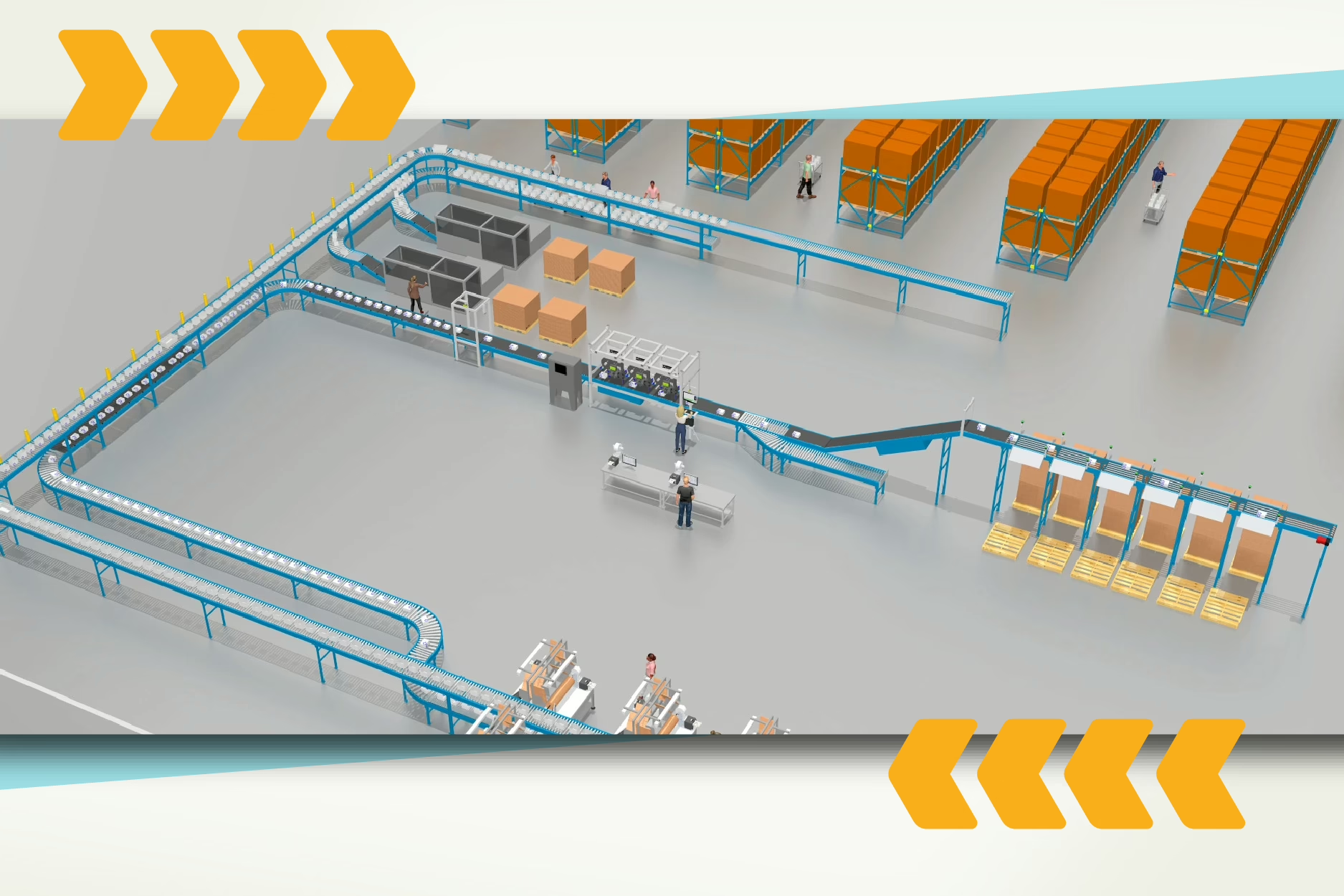

StreamTechEngineering has extensive experience in implementing complex sortation automation installations for a wide variety of clients. Utilizing a combination of both our sortation hardware and the StreamTech WCS software, we provide cost-effective, user-configurable sortation systems for abroad range of applications. With deep expertise in material handling best practices, StreamTech designs custom solutions tailored to your operational goals and the specific types of products you handle — ensuring your system performs efficiently and accurately in your unique environment.

Considerations for Sortation

Package Profile

The types of packages make a big impact in the correct sort technology. There are certain sorters which are best suited for boxes, while others work well for bags, padded mailers, flat envelopes, or loose garments. There is no “one sites fits all” sorter.

Size & Weight

Understanding the length and width of each package will determine how large each sort location or lane needs to be, and how well each item will transfer. Weight data is important to specify the correct technology, for both convertibility and weight limits.

Sort Data

Is the sortation data in the LPN barcode? If sorting by carrier, some customers choose to scan the shipping label after it has been applied. In other cases, sort data could be determined by dimensions, sorting by large/ small or by package type/

Throughput Goal

Throughput is often the data point cusomters focus on first. How many packages will need to be sorted in a given timeframe? Typically we measure daily or hourly package throughput. Each sorter technology has a maximum rate, so we’ll ensure your system is designed to meet your goal, using the appropriate technology.

Number of Locations

The number of locations will typically be the data point used to determine how many individual sorters are necessary. For many technologies, one sorter can divert to two locations. There are some technologies that allow multiple locations on one belt.

Destination Type

The type of destination will have an impact on how the system is designed. If sorting to gaylords or mail carts, it’s important to understand the volume of the bin, the throughput, and how fragile your items are. Items could also be sorted into a variety of lanes leading to dock doors.

How Automated Parcel Sortation Works

Automated sortation is the backbone of fast, accurate fulfillment. By directing packages to the right destination at the right time, it ensures smooth downstream operations and faster order cycles.

From the moment a package enters the system to its final scan, every step is optimized for precision and efficiency—minimizing errors, reducing manual touches, and keeping your operation running at peak performance.

Sorting Technology

ModSort®

Omni-Directional Roller Ball Sortation

ModSort® provides an all-electric solution to handling a wide variety of form factors, in a compact footprint. ModSort® is suitable for bags, boxes or flats- even very light items as long as they make contact with enough of the balls on the transfer belt. This system has a modular design, can be used for alignment, and can transfer at angles as well to keep product flow consistent.

- Sort at up to 40 products per minute Low voltage all-electric design High range of motion control available

- Great for many types of mixed products

- Up to 50 lbs product weight

Urethane Belt Transfer (UBT)

Energy Ecient, Gentle 90° Transfer – Great for Boxes

An MHS Conveyor product, the UBT is designed for transferring and sorting boxes into gaylords, to gravity, between conveyor lines or within pick zones, the UBT is ideal for distribution centers and order fulfillment operations. It provides bi-directional movement and high-speed performance.

The UBT uses urethane belts or wheels to move products at shallow or 90-degree angles with reliable control.

- Sort at up to 30 products per minute

- Available with pneumatic lifts or all electric

- 75 lbs. total transfer load capacity

- Works well for boxes, not used for bags or small items

Narrow Belt Sorter

30° Single or 90° Bi-Directional Sortation

An MHS Conveyor product, the NBS is available in multiple configurations. With the Narrow Belt Sorter, the object conveys on the belts, and roller wheels are lifted to transfer the object at either a 90° or 30° angle.

- Low cost solution

- Works well for polybags, padded mailers, boxes

- Bi-directional sortation

- Up to 10 lbs product weight

- Recommended product thickness greater than 1/2 inch

Activated Roller Belt

Intralox® High Speed Roller Belt Sortation

Capable of sorting nearly any type of item—including difficult-to-handle products like polybags, cartons, and irregular shapes. It handles a wide range of product sizes, from as small as 2 x 2 inches up to 60 x 60 inches, making it ideal for sorting everything from lightweight parcels to large, bulky items.

- Custom-designed to each application

- High throughput – up to 15k parcels per hour

- Bi-directional sortation at high speed

- Requires minimal gapping of product (4 in)

- Can handle heavy items

SoftSort™ Sweep Sorter

All Electric Servo or Pneumatic Push Sweep Sorting

StreamTech has developed novel ways to sort complicated items for parcel e-commerce. Available in either all-electric or pneumatic technology, the sweep sorter allows bi-directional sortation of bags, padded mailers or boxes.

- Custom-designed to each application

- High throughput – up to 15k parcels per hour

- Bi-directional sortation at high speed

- Requires minimal gapping of product (4 in)

- Can handle heavy items

Intelligent Sort Control

Powerful WCS Sortation Software

In addition to monitoring exceptions, faults and verification in the WCS, StreamTech’s Sortation automation module allows customers to define their own Sort Codes, and sign them to each lane, using a drag-and-drop configuration. This allows ultimate flexibility to change and re-define the lanes as needed.

Users can also define and save “recipes.” If there are a few different sort lane configurations that are used often – maybe during different times of the year – they can save them and easily switch all lanes at once.

The Sortation software also monitors lane full conditions, allowing either overflow to another lane, or a pause of the sorter altogether.

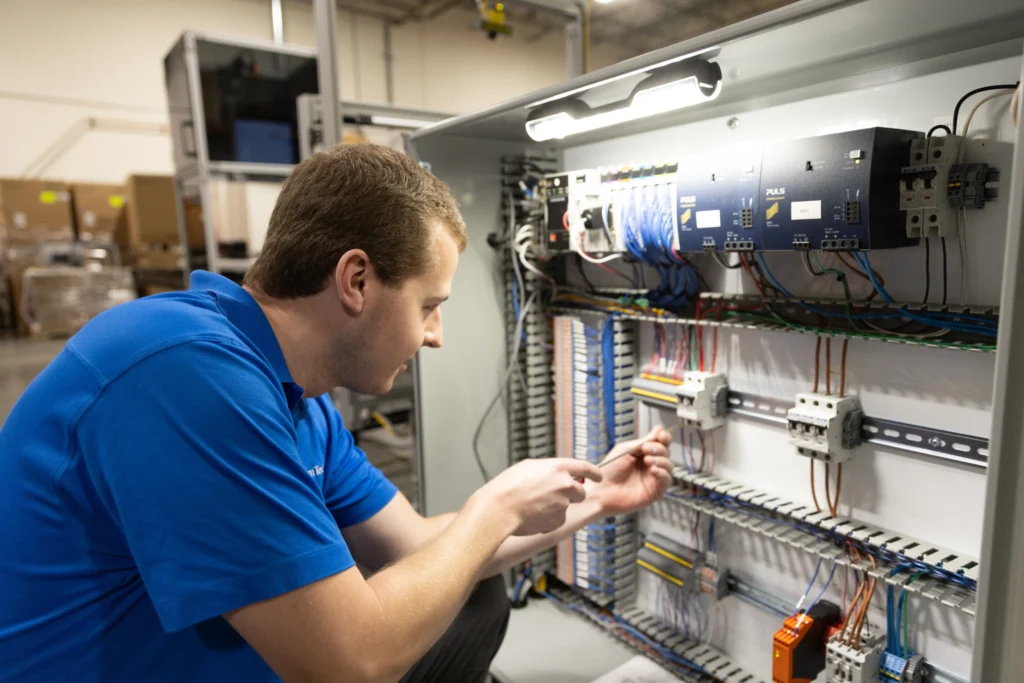

Integrated Controls Hardware

StreamTech designs, builds and installs the control panel to match up with the WCS software and hardware on your parcel sortation automation system.

Machine control is provided by an Allen Bradley CompactLogix PLC, which is easily expandable to manage additional automation. Its open architecture means that end users are able to support themselves if desired.

- Add diverters, merges, etc.

- Open, standard PLC architecture

- All devices IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low cost system control of reseller conveyor equipment

- EWON remote support router included (no VPN needed)

What our customers say

Frequently Asked Questions

If you have any further questions, please don’t hesitate to contact our customer support team for assistance.

Good news, you do not have to choose. The StreamTech Engineering Applications team partners with you to understand your package types, volumes, and operational goals—then recommends the ideal system tailored to your needs.

Typically the best practice for parcel sortation is for the customer’s parcel manifesting software to provide StreamTech’s WCS with a sort code for each package. However, for customers who cannot pass sort codes, StreamTech can interrogate the shipping label and apply rules based upon pre-configured algorithms.

Yes, StreamTech can design a sortation system that has pre-programmed PLC code designed to interrogate the shipping label and determine which of the sort rules to apply to each package. This has downsides however – if a new rule needs to be added, it requires StreamTech’s Engineering Team to update the PLC code. For some customers though, this can be a good option.

For customers using StreamTech’s WCS software, the Sort module features an intuitive drag-and-drop interface on a Windows PC, making lane configuration simple. Users can either select from pre-configured recipes or manually adjust individual lanes to redirect packages based on type.

For customers without StreamTech’s WCS software (PLC code only) – contact StreamTech’s Lifetime Services to request a quote to update your PLC code.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields