Warehouse Control System (WCS) Software

The brain of your material handling integration.

Lightweight control, full power. Sync, track, deliver.

StreamTech’s Warehouse Control System (WCS) serves as the central hub for your fulfillment automation — delivering the real-time visibility and control you need, without requiring your business to revolve around it. Designed to be lightweight, low-maintenance, and adaptable, our WCS integrates seamlessly with your material handling systems and order database to manage picking, packing, shipping, and sortation in real time.

With streamlined data flow, synchronized operations, and intuitive monitoring tools, you gain powerful control of warehouse performance while keeping your business flexible and free to evolve on your own terms.

Intelligent Software Modules

Pick

Control picking operations, including pick-to-light. Manage the number of items per pick, and match them to live orders, decrementing as orders are completed.

Receive

Control multi-sided scanning with order lookup. Allows a warehouse to automatically receive inventory and distribute to a storage location.

Sort

Manage and control sort lanes. Allows the configuration of all sort rules, logs any sort errors and package exceptions.

Pack

Associate picked orders to their respective cartons, so they can be identified and managed along the automation.

Ship

Synchronize outbound shipping, for automated scan, weigh, dim, print-apply manifesting systems, in connection with TMS software. Log all shipped orders throughout the process.

Confirm

Sends all order shipment confirmation statuses to customer’s ERP, WMS or other TMS software database.

Insert

Manage document automation systems. Allow the configuration of pack slips, track document insert process.

Verify

All order information printed and inserted or applied to the outside of the carton can be verified with a barcode read for ultimate order integrity.

Void

Dynamically calculates remaining void space within an outgoing box. Controls void fill machine to automatically achieve consistent fill portions.

Connect to your platform or database.

Integrates with your ERP, WMS, Multi-Carrier System. StreamTech has experience with integrating our WCS software with the many software platforms in the market, and has worked to develop standardized connections with some of the leading platforms. The WCS can also connect directly to an in-house database or can operate via batch data exports.

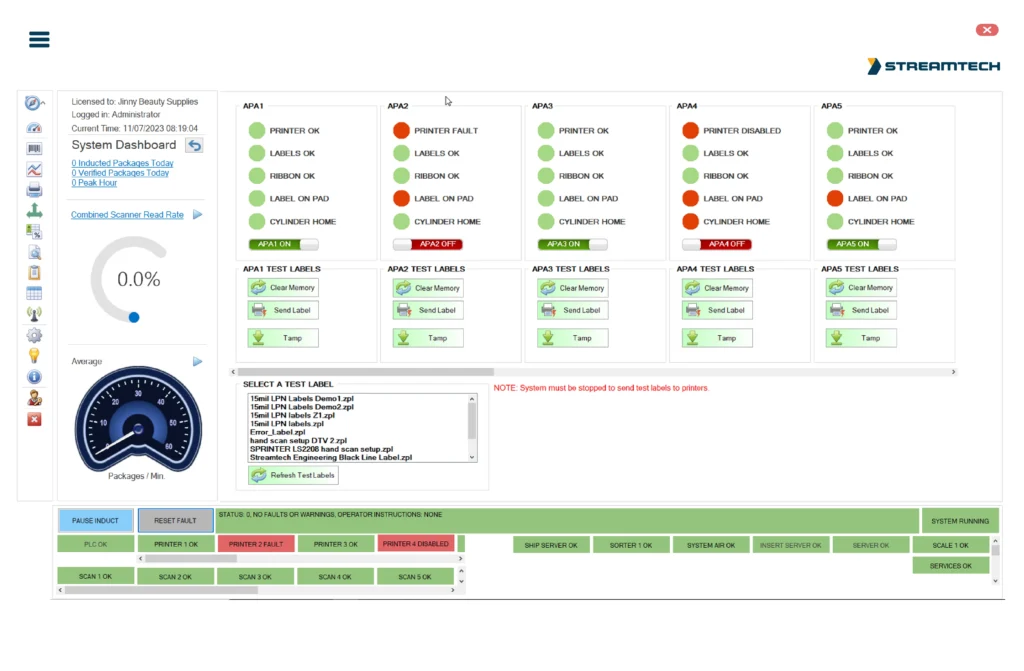

Real-time machine status and settings.

Easily see alarm statuses, maintenance and troubleshooting notifications.

Quick system configuration on the fly.

Add or modify sortation rules, redirect printer signals, update label and document templates.

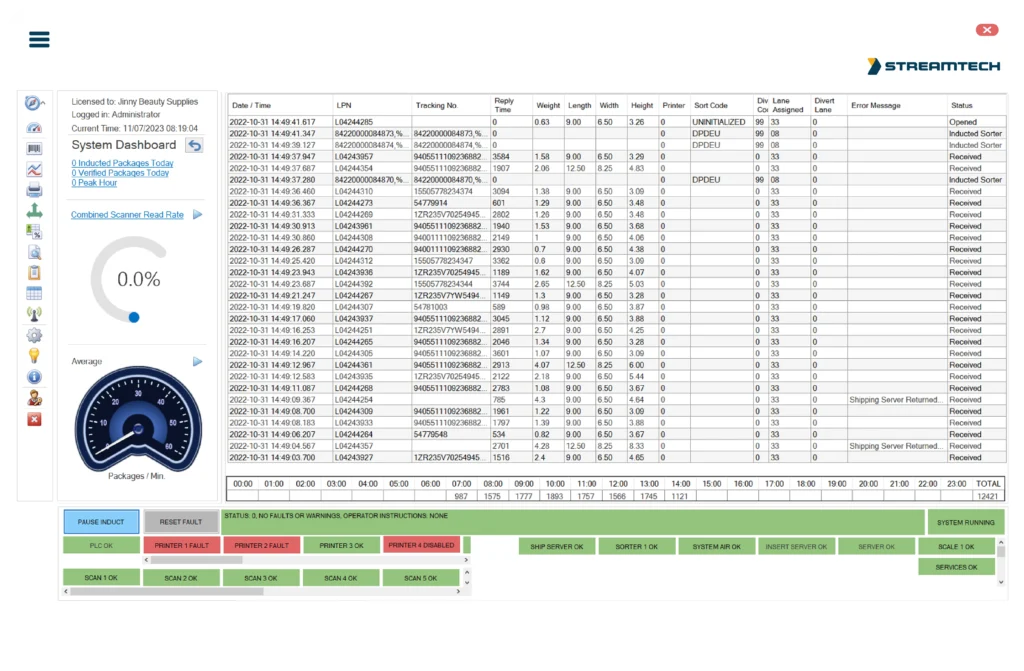

Rich data insights, metrics and reports.

Logs all order flow through the warehouse, with charts, spreadsheet exports, and live dashboards.

Machine Control

Machine control is provided by Allen Bradley PLC, which is easily expandable to manage additional automation. Its open architecture means that end users are able to support themselves if desired. Larger projects can have multiple 480V control panels and multiple PLCs. Smaller, stand-alone systems that plug into a single 120V wall outlet are also available.

- Add diverts, merges, etc.

- Open, standard PLC architecture

- Devices are IP-addressable for instant, world-class support

- Easily modified and expanded; smaller systems can grow without a large reinvestment

- EWON remote support router included (eliminates need to go through VPN)

Frequently Asked Questions

If you have any further questions, please don’t hesitate to contact our customer support team for assistance.

StreamTech’s WCS is a lightweight software that can work as an intermediary to help manage the full scope of material handling operations—picking, receiving, packing, sorting, shipping, verification, and document insertion. It acts as a central hub that connects your equipment, controls, and order database for real-time, end-to-end management.

Yes, the WCS allows on-the-fly configuration. You can update sortation rules, redirect printers, modify document or label templates, and more—without needing to reprogram or pause operations.

StreamTech’s WCS integrates with a wide range of ERP, WMS, and multi-carrier platforms. The software is integrated using standardized protocols such as TCP/IP, Rest API, shared directory or database connection, among others. It also supports custom integrations to specific software suites. We have yet to encounter a software we could not work with.

The WCS provides live dashboards, logs all order flow, and allows spreadsheet exports. It also shows real-time system status, alarms, and maintenance notifications, giving operators full visibility into every step of fulfillment.

While a WMS manages inventory and orders, the WCS sits closer to the warehouse floor—controlling automation equipment, synchronizing real-time actions, and handling system-level logic for things like sortation, scan-weigh-dim, and label application. It’s the execution layer that turns warehouse plans into real-time performance.

No. StreamTech’s WCS software is provided as a one-time perpetual license (per system), as it is typically purchased as part of a larger integrated equipment solution.

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields