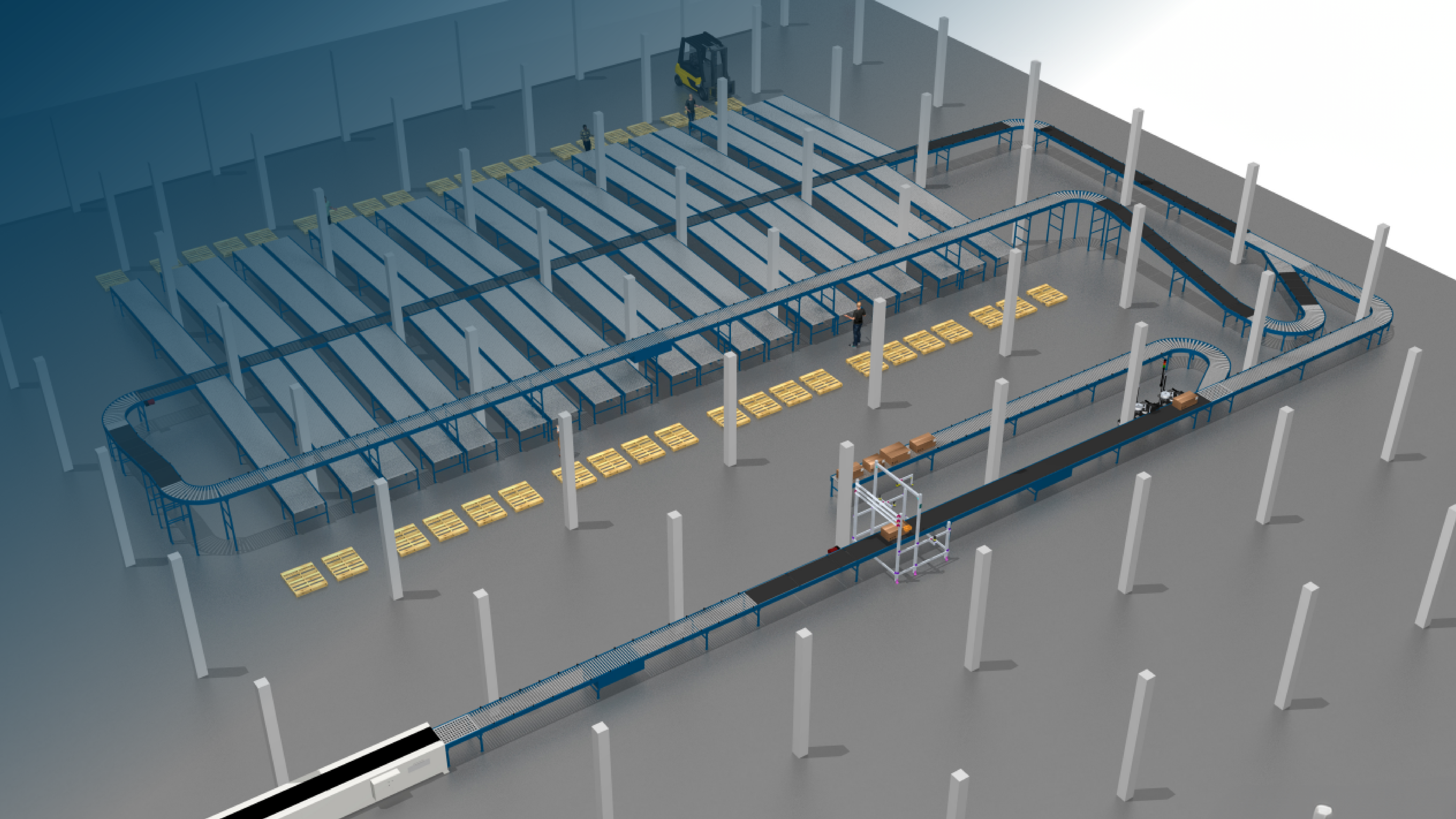

When it comes to fulfillment automation, receiving and shipping systems might look similar on the surface—scan tunnels, conveyors, labelers, sort logic—but the operational goals behind each are fundamentally different. Receiving systems are designed to capture and verify inbound inventory. Shipping systems are built to finalize and release outbound orders. Designing automation for each requires throughput equipment, tailored logic, and software integration.

Below, we break down the key differences and design considerations for receiving vs. shipping automation.

Receiving – First Steps: Unload, Identify & Gather Data

Receiving Part 1: Rapidly unload, identify all incoming orders, while recording accurate data about all items received.

The initial goal of a receiving system will be to aid your team in unloading the truck rapidly, while scanning all items, recording the data about each one for reporting purposes. This initial induction point is critical in keeping accurate account of what SKUs are in inventory, how many, and also holding the delivery truck accountable for missed shipments.

Key challenges in the initial unloading process:

- Multi-sided scan tunnels are often necessary due to unpredictable barcode placement on items coming in from the truck

- Difficult-to-scan barcodes due to inconsistency – some UPC, some LPN, some inkjet while others are labels

- Receiving systems need to be able to keep a count of all items received from the truck in order to match them against expected quantities

- Logging scan and label data for feedback to the inventory management for delivery (truck) auditing

Receiving – Next Steps: Label, Verify, Route

Receiving Part 2: Label, Verify and Route Inbound Shipments.

The second step of a receiving system is to determine what action needs to be taken on each of the inbound items. Whether you’re unloading trailers of full cartons, mixed pallets, or individually packaged goods, the goal is to scan, label, and direct products to storage, crossdock, or staging for retail store replenishment as efficiently as possible.

For some companies, the labeling process means simply routing for a store, while others will actually weigh, dimension and manifest each product straight out to the dock in a crossdocking configuration direct to the consumer.

Other companies may simply need to put their own internal SKU tracking label on each product, and route them by product code or category.

Key actions for the receiving system:

- Labeling logic for compliance vs internal routing, or crossdock manifested shipments

- Real-time database lookup (e.g., ASN reconciliation)

- Exception handling – diverting all unknown, unreadable or mismatched items to QA station for individual review

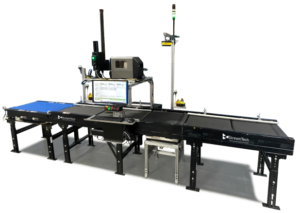

Shipping – System Handoff: Scan, Label & Sort

Identify the order, gather weights, dimensions, and manifest with the carrier. Shipping automation takes over after orders are picked and packed. Systems like the Sprinter™ ensure packages are accurately scanned, labeled, and sorted to the right carrier lane based on rate-shopping and service levels.

Key features in shipping automation:

- Single-sided scan tunnels with controlled label orientation

- Carrier label generation via WMS, ERP, or multi-carrier software

- Rate shopping and manifesting

- Sortation by carrier, service level, or zone

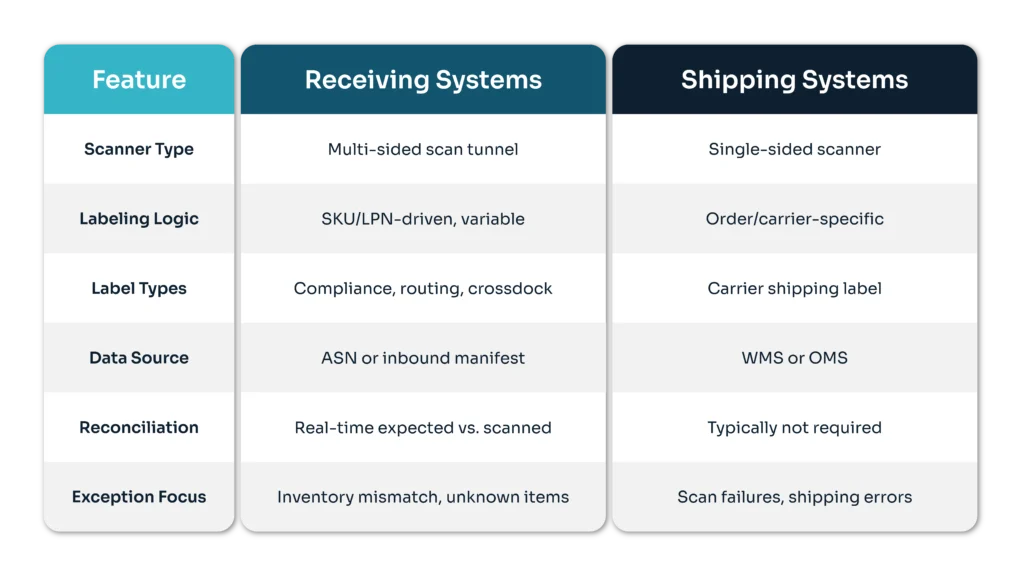

Scanner and Labeling Design

Receiving systems need to read whatever shows up—labels on any aide, sometimes upside-down, simply due to the fact that the team unloading the truck will be moving quickly, and the varieties of product manufacturers will have barcodes in different locations on their boxes. These barcodes may be labeled, or inkjetted on. That calls for high-performance, multi-sided scanning.

Shipping, on the other hand, benefits from label consistency because the outbound process is controlled by one party, enabling faster, lower-complexity single-sided scans.

Similarly, receiving label logic varies by use case. Some cartons may need store tags, compliance labels, or shipping labels (in the case of crossdock). Outbound shipments almost always need a carrier label, triggered by LPN, order ID, or WMS handshake.

Data & System Integration

Inbound: Receiving automation often relies on pre-loaded shipment data (e.g., ASN or inbound manifest). As each item is scanned, the system verifies its identity, applies the correct label, and triggers a routing action. Real-time reconciliation helps spot discrepancies—like missing or extra cartons—early in the process.

Outbound: Shipping automation typically works off predefined orders. As soon as a carton enters the line, it’s linked to a known order. The system verifies the match, calculates shipping rates, requests a label, and routes the package to the correct carrier.

Exception Handling: Different Triggers, Same Need for Visibility

- Receiving exceptions: Missing barcodes, unknown SKUs, quantity mismatches

- Shipping exceptions: Failed scans, mislabels, invalid carrier data, dimension discrepancies

Both areas demand visibility and smart exception routing. StreamTech’s WCS enables real-time alerts, logging, and diagnostics across both systems.

Comparing Core Design Requirements:

From Receiving to Shipping: Scalable Fulfillment Starts With the Right Fit

While both receiving and shipping automation leverage scanning, labeling, and sortation technologies, their business logic diverges. One is built to ingest and validate unknown inventory; the other is engineered to confirm and dispatch customer-ready orders.

Recognizing these distinctions—and designing for them—is key to building automation that scales with your operation. Whether you’re upgrading a receiving dock or adding an outbound line like the Sprinter, StreamTech helps engineer the right fit for each phase of your fulfillment process.