Technology

Explore Insights, Tools, and Answers

Stay informed with the latest in shipping automation and logistics. From expert articles and upcoming events to product videos and helpful FAQs, our resource center is here to support your operations and keep you ahead of the curve.

-

Technology

TechnologyHow Image-To-Order Capture Provides Accountability For Outbound Fulfillment

-

Technology

TechnologyGoods To Person (G2P) Robots Are Just One Piece Of An Integrated, Intelligent Warehouse

-

Technology

TechnologyHow Pick to Light Systems Increase Accuracy and Speed in Warehouse Operations

-

Technology

TechnologyWhat Is Warehouse Control Software (WCS), And Why Is It Critical To Get Right?

-

Technology

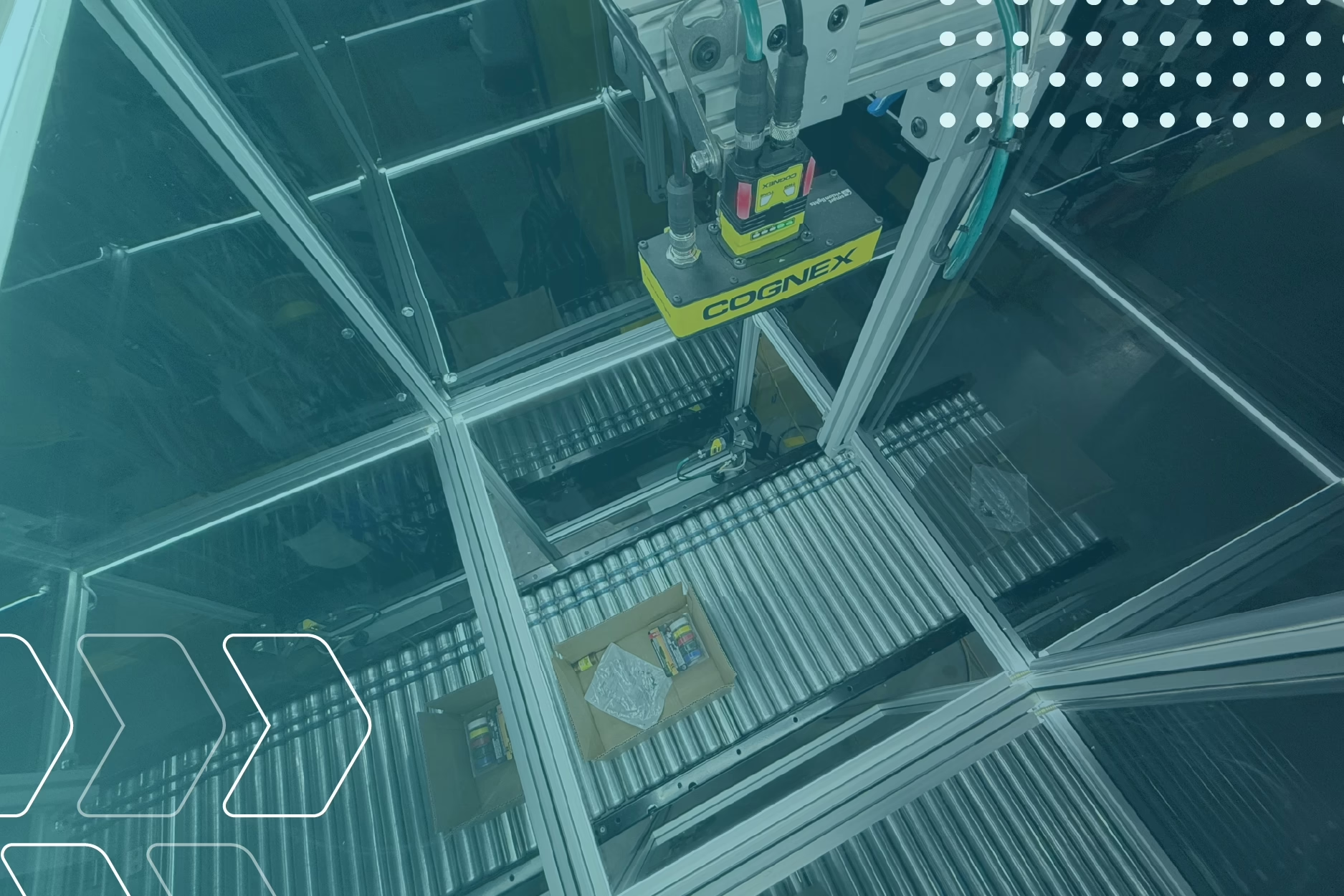

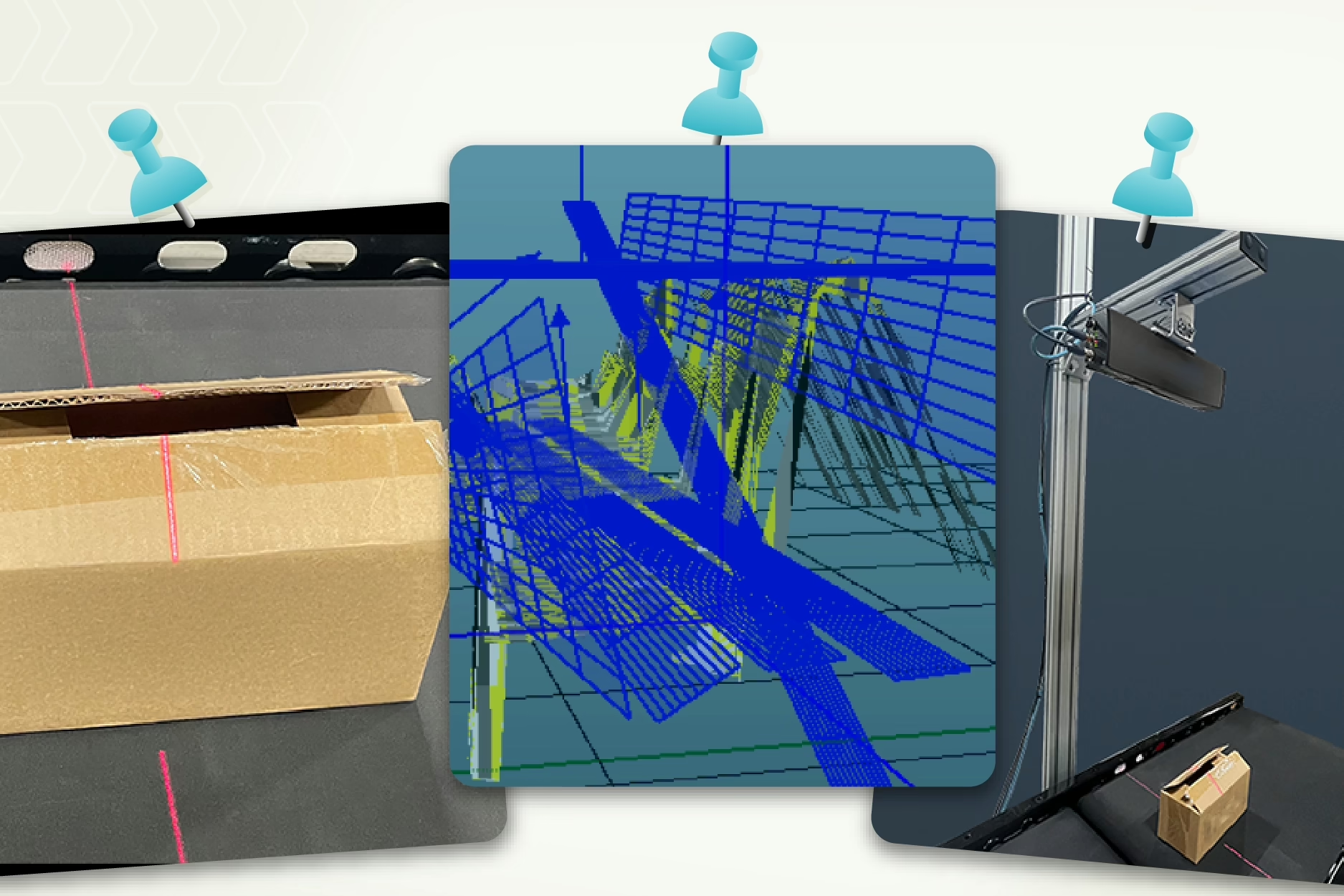

TechnologyPackage Inspection System

-

Technology

TechnologyStreamTech Announces Patent Award for FoldSerter™ Intelligent Pack Slip Print, Fold, Insert System

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields