Estimated reading time: 8 minutes

While there are a lot of elements to running a distribution warehouse—labor, accuracy, speed, costs—at the end of the day, it is a business controlled almost entirely by dimensions. The dimensions of the space in your warehouse, of the items in your racks, down to the dimensions of each box, and even the dimensions of the truck that takes each order away…all of these need to be measured accurately in order to plan effectively.

In other words, controlling these elements is critical to running a successful distribution and fulfillment center, and if not kept in check, you’ll find these dimensions controlling you. What do we mean by this?

Take something simple, like packing and shipping. At first glance, it might appear that little can be done about costs here: Customers today expect free shipping, and yet carrier costs are significant, even when everything runs smoothly. Problems like inaccurate measurements of dimension and weight, or using the wrong packaging, can incur stiff penalties…making shipping even more expensive.

While you might not have much control over the dimensions or weight of your products, getting accurate measurements of your packages for shipping—that is, getting a handle on the dim weight—can be a surprisingly effective way of controlling hidden shipping costs and chargebacks. This is made possible through the use of automated DIM weight equipment.

Understanding Carrier Costs and DIM Weight

To understand where some avoidable shipping costs are hiding, it helps to review how DIM weight works.

Dimensional weight (DIM weight) is a method of pricing based on measuring a package’s volume in relation to its actual weight. Carriers adopted DIM weight as the standard for shipping charges to optimize the space in their vehicles.

DIM weight is calculated with a simple mathematical formula:

(length X width X depth) / DIM divisor

The DIM divisor, also called the DIM factor, is a value set by carriers and represents cubic inches per pound. For example, the current DIM divisor for UPS and FedEx is 139, while the DIM divisor for USPS domestic priority mail is 194.

Thus, DIM weight is determined by getting the volume of the package (based on its dimensions) and then dividing by the DIM divisor, which is then rounded to the nearest whole number. Charges are based on the resulting DIM weight or the actual weight, whichever is greater.

Example: A box measuring 10” X 12” X 8” has a DIM weight of 7 pounds. (10 X 12 X 8)/139 = 6.9, rounded to 7. Pricing is based on 7 pounds, even if the actual weight is less. However, if the actual weight is 8 pounds or more, pricing is calculated by that number.

Carriers use DIM Weight because it affects how much cargo they can plan to carry in their trucks (planes, etc.). Reporting the dimensions of a package to the carrier is a key to their efficiency, and so they set up incentives to do this accurately. (This is also an argument for why you need a multi-carrier TMS that can connect your fulfillment systems.)

All that said, there can be more to your overall shipping bill than simply DIM weight charges. This is especially true for warehouses that work at scale: A few dollars per shipment might not make a difference when sending a dozen packages in a day, but when sending hundreds or thousands, small fees and pricing inefficiencies add up quickly.

1. Avoid Chargebacks

If a company records the wrong dimensions or weight on an outgoing package, or only lists dimension or weight but not both, two things can happen: The carrier will adjust the base charge accordingly using DIM weight, and they may also charge an additional fee (chargeback) per parcel that has missing or incorrect information. (Note that the process of correcting this can potentially delay the shipment, too.) Relying on your vendors’ inventory master lists for dimensions and weight can be problematic here—if their data is wrong, you could be paying for their mistakes! (Again, not having control of your dimensions means you will find these dimensions controlling you.)

Fee amounts vary by shipper and fluctuate over time, but range from about $1 per package to 5% or 6% of the amount of the price adjustment. Regardless of how they are calculated, chargebacks can accumulate fast as throughput increases.

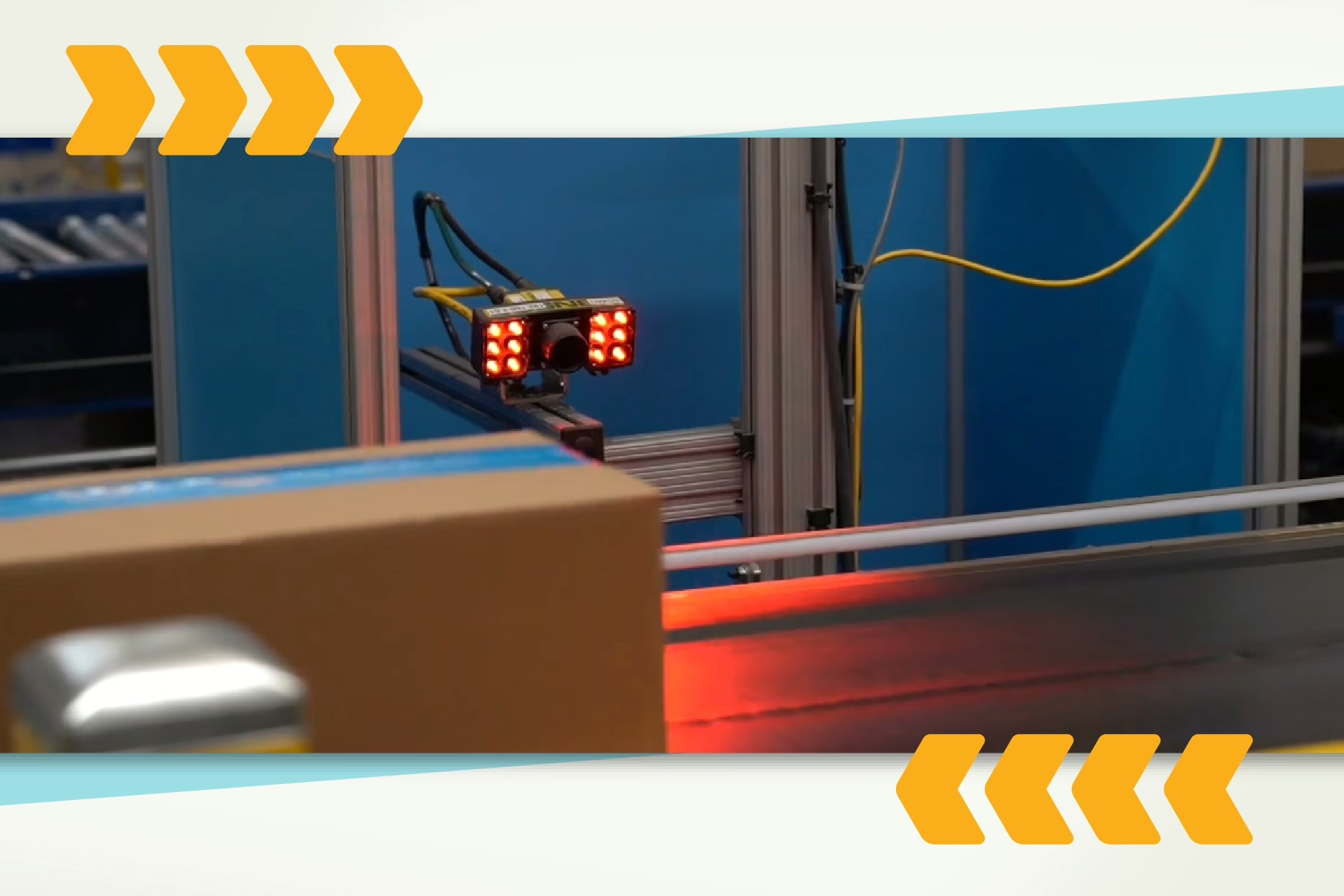

We integrate dimensioning cameras and light curtain dimensioning systems into our shipping systems regularly.

For all but the smallest companies, trying to accurately measure and weigh packages by hand is a non-starter. The most basic advantages of adding DIM weight machines are that they provide thorough data and eliminate human error. They can also go much faster than any manual system. Equipment like StreamTech’s Sprinter™ can scan, weigh, measure dimensions, and print and apply labels for between 600 and 1,000 boxes per hour, without making a mistake.

2. Right-Size Packaging

Another source of unexpected shipping fees is a handling surcharge for packages that exceed size or weight limits, or that are not in a squared box. For example, boxes heavier than 50 pounds, or measuring more than 48 inches on the longest side, can trigger surcharges of hundreds of dollars from FedEx.

While the size of parcels can’t always be controlled, making sure to use the smallest box possible will help. We’ve all laughed when a huge box arrives at our doorstep, with one small item inside, accompanied by lots of void fill. This is obviously not efficient.

In many fulfillment operations, the selection of the right box size (called cartonization) is left up to an operator’s sole discretion during the packout process. A material handling systems integrator such as StreamTech, can use a cartonization algorithm integrated right into our Warehouse Control System software (WCS) and take this guesswork out of the process.

Ideally, various types of packaging equipment should be integrated which can build a box on-demand to match the size of each order. Some systems employ complex machines to build a box around each item; others build a cardboard tray, then add a lid, and still others employ robotic arms to select each box. StreamTech Engineering can work with you to help find the right equipment for your operation, all designed to control the dimensions of each box.

Automating these processes also gives managers the tools to make better, more cost-effective packaging and shipping decisions. Perhaps orders might be split into two or more cartons so they’re not overweight, disassembled to fit in a smaller box, or more suited to an alternative packing material like a padded envelope.

Optimizing cartonization eliminates wasted space in each parcel and minimizes the DIM weight—and therefore shipping charges. You’ll know ahead of time that something is heavy enough or big enough for surcharges to kick in, instead of being surprised with an invoice.

3. Rate Shopping By Carrier

Another way that automating DIM weight helps the bottom line is by allowing carrier rate shopping in real time.

Carriers differ in their pricing models and requirements, and fees change frequently. StreamTech’s WCS software has the ability to integrate with multi-carrier TMS software. Together with accurate, automated DIM weight data, the warehouse system can automatically scan the various shipping options available, choosing the carrier that offers the best price (along with other criteria, like on-time records and return stats). Once chosen, the system can create and affix the appropriate label, further streamlining the process.

Over time, this kind of rate shopping will allow your fulfillment center to find ways to use your annual carrier spend more efficiently, and without massive manual intervention.

Take Control of DIM Weight Before It Takes Control of You

Fulfillment centers live and die by dimensions; taking control of their measurement and use means controlling a large part of your costs.

Here we’ve seen how automating DIM weight calculation minimizes the human error in weight and dimension estimation, allowing companies to avoid unexpected surcharges and maintain more predictable shipping costs. Additionally, the real-time rate shopping and automated labeling eliminate time-consuming steps, freeing warehouse staff to focus on higher-value tasks. StreamTech’s WCS software ensures that each shipment meets carrier specifications for both price and performance, enabling consistent, cost-effective delivery and enhancing customer satisfaction.

And while measuring DIM weight may not seem like a top priority when deciding how to automate your warehouse, implementing dimensioning equipment can have a relatively large impact. When every package can be scanned, weighed, and measured efficiently, ensuring that only accurate information is provided to the carrier, things like chargebacks, special handling fees, and bad packaging decisions become a thing of the past.

Fill out the form below or call us to discuss how StreamTech can help.

Key Takeaways

- Dimensions drive everything in a distribution or fulfillment operation. Accurate measurement of space, boxes, and shipments is critical for efficiency and cost control.

- Automating DIM weight measurement removes human error, reduces chargebacks, and improves accuracy in reporting to carriers.

- Right-size packaging eliminates wasted space, avoids surcharges, and helps control shipping costs.

- Automated cartonization systems select or build the correct box size for each order, ensuring consistent and cost-effective packing.

- Real-time rate shopping between carriers allows fulfillment centers to choose the most efficient and economical shipping option every time.

- Integrating dimensioning and carrier systems through StreamTech’s WCS software streamlines labeling, rate selection, and reporting for each shipment.

- Taking control of dimensions means reducing hidden costs, increasing throughput, and improving customer satisfaction.