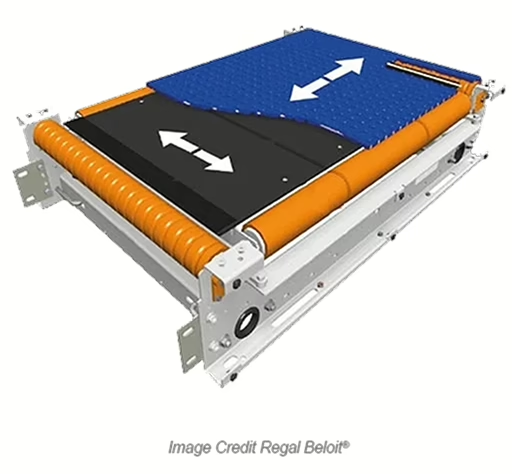

Flexible Sortation Made Simple

The ModSort® Flexible Sorter is engineered to make multi-directional sortation easy, with a modular design that adapts to changing fulfillment needs. Its quiet, low-maintenance rollers and compact footprint make it ideal for handling polybags, cartons, and jiffy packs without disrupting operations.

Whether you’re diverting by carrier, zone, or order type, ModSort® scales effortlessly to match demand—delivering precision and reliability with every sort.

Features of Modsort

Handles Diverse Parcel Types

Effortlessly sorts cartons, polybags, jiffy packs, and irregularly shaped items without jams or slowdowns, improving throughput and ensuring consistent performance across a wide range of SKUs.

Compact, Quiet Footprint

Operates with low noise and minimal vibration, enhancing employee safety and comfort, reducing workplace disruptions, and allowing placement even in space-constrained or noise-sensitive areas.

Scalable Architecture

Grows seamlessly with your business by enabling the addition of modules or units without costly reconfiguration, helping you increase capacity and adapt to future growth without interrupting operations.

Modular Technology

Easily integrates into new or existing conveyor systems, minimizing installation time, reducing engineering costs, and giving you the flexibility to adapt your layout as operations evolve.

Omni-Directional Travel

The roller ball chain allows packages to transport along the belt in any direction. This allows the system to convey product at angles to keep the leading edge of the product traveling in the direction of flow.

Allows for Creative Material Handling

In situations where alignment needs to be done in a short distance, ModSort can be a great tool to quickly move packages to one side of the conveyor or the other. Additionally, ModSorts can be split into multiple divert locations to save costs.

How ModSort Works

The Modsort® utilizes the System Plast™ 2253RT roller top belt, which allows it to transfer and divert packages. The sphere’s vector speed, direction, and 1-inch, on-center sphere array allow for very small packages to be diverted.

The station can divert in a continuous motion or stop and divert at a true 90-degree angle. The Modsort® is ideal for polybags, small packages and also easily handles boxes.

- Motorized Drive Rollers (MDR) controls

- 24-volt DC motor and controls that allow flexibility in wiring and control

- Can divert exceptionally small packages and boxes

- Safe, energy-efficient, quiet and low-maintenance

- Can be programmed standalone or interfaced to a PLC

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

What types of parcels can ModSort handle?

ModSort is designed to handle a wide variety of parcel types, including polybags, jiffy packs, cartons, and irregularly shaped items. It’s especially effective at sorting lightweight or small parcels that are difficult to control on traditional conveyor systems. (No sorter can handle everything, and as long as the lightweight item has a flat bottom for adequate surface area contact, the ModSort can be a good fit. We are always happy to test your product in-house).

Can ModSort integrate into my existing conveyor system?

Yes! ModSort is built with modularity in mind. It easily integrates with most existing conveyor setups, reducing installation time and engineering costs. We’ll work with your current system layout to ensure a smooth implementation.

How does ModSort handle directional changes?

The ModSort module uses a System Plast™ roller top belt and motor-driven rollers to move packages in virtually any direction. It can stop, start, divert 90 degrees, or continue forward—providing unmatched flexibility in how parcels are routed.

Is ModSort a good fit for high-volume operations?

Absolutely. ModSort can be scaled with multiple units to meet growing demand, and it’s low-maintenance and energy-efficient—making it a strong fit for high-throughput fulfillment environments.

Can ModSort handle split or multi-destination sorting?

Yes, ModSort excels in environments where packages need to be diverted to multiple locations. Whether you’re sorting to multiple outbound lanes or handling zone-based routing, we can configure your ModSort system to meet your exact needs.

Our flexible sorter is low-maintenance by design. The components are built for longevity and efficiency, and our team provides training and support to ensure your system stays in peak condition.

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields