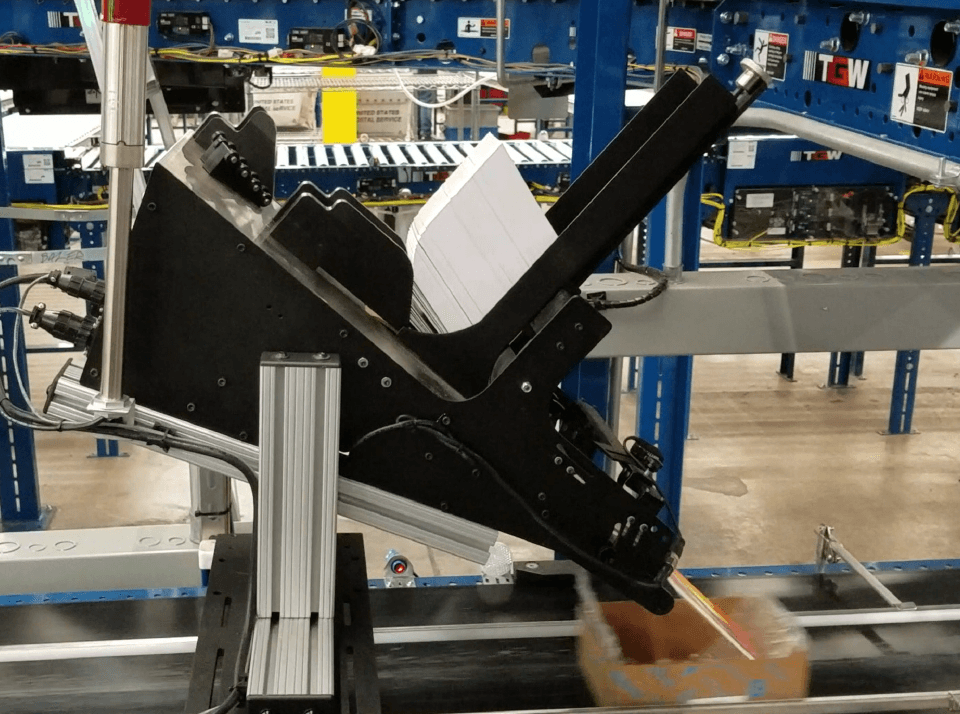

Automate Cards Into Open Cartons

HIGH SPEED FRICTION FEEDER FOR PRE-PRINTED COLLATERAL

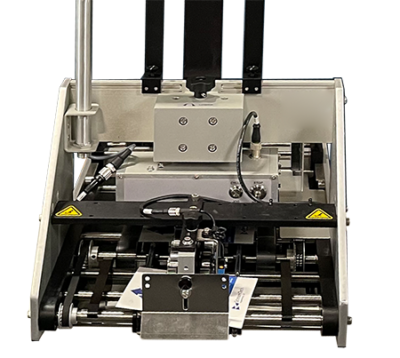

The CardSerter™ document friction feeder automates pre-printed collateral insertion to open boxes. This system allows for pre-loaded postcard-sized documents to be added to the pack line. Ideal for adding marketing or promotional collateral to outbound orders.

- Up to 3,000 boxes per hour, per line.

- Great way to increase customer satisfaction and repeat business.

- Add marketing collateral to outbound orders.

Automate Cards Into Open Cartons

HIGH SPEED FRICTION FEEDER FOR PRE-PRINTED COLLATERAL

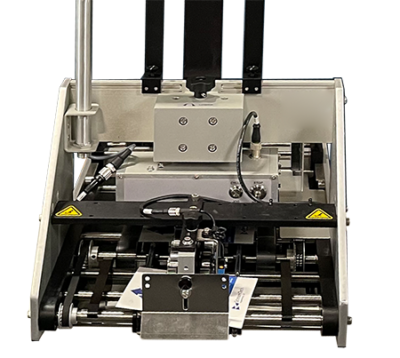

The CardSerter™ document friction feeder automates pre-printed collateral insertion to open boxes. This system allows for pre-loaded postcard-sized documents to be added to the pack line. Ideal for adding marketing or promotional collateral to outbound orders.

- Up to 3,000 boxes per hour, per line.

- Great way to increase customer satisfaction and repeat business.

- Add marketing collateral to outbound orders.

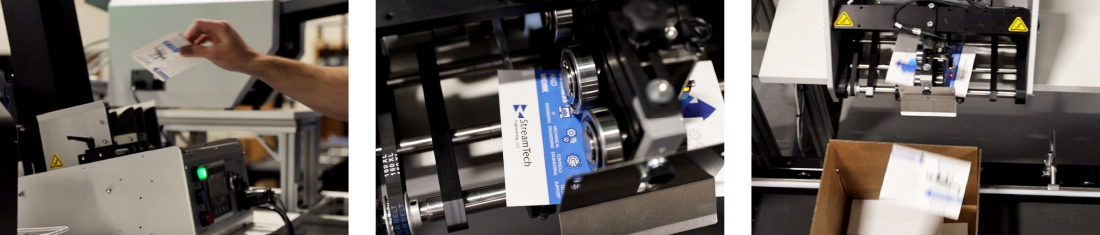

How Does CardSerter™ Work?

CARDSERTER™ QUICKLY AND ACCURATELY FEEDS PRE-PRINTED CARDS

Easy to Operate:

JUST LOAD YOUR CARDS AND THE SYSTEM AUTOMATES THE REST

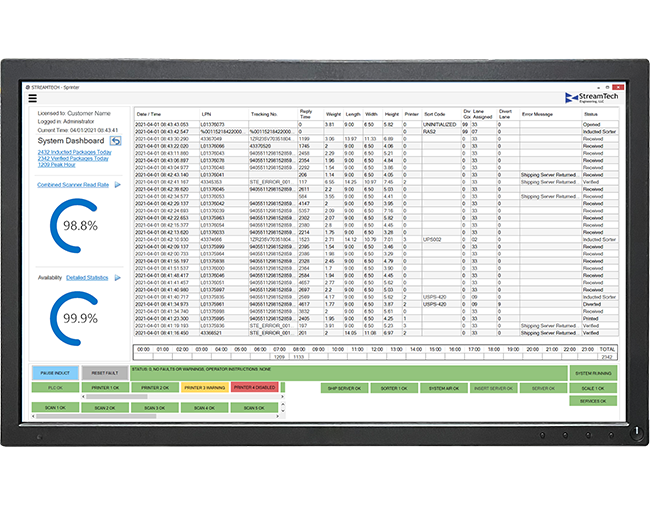

Intelligent Warehouse Control System (WCS) Software

StreamTech bundles our operational and maintenance know-how in the onboard software app that comes on the included Windows Pro 64-bit SSD PC, with rich functionality that supports troubleshooting and enhances uptime. The software easily integrates with rules-based multi-carrier systems or direct carrier interface.

- Extensive troubleshooting built-in to system.

- Smart Filtering of Label Files.

- Expandable for growing customers.

- Rich scan, production, and maintenance statistics with configurable retention.

- Server-based thin client solutions available.

- Backup UPS included to protect PC and SQL database.

- Multi-Level Security, Multi-User Login.

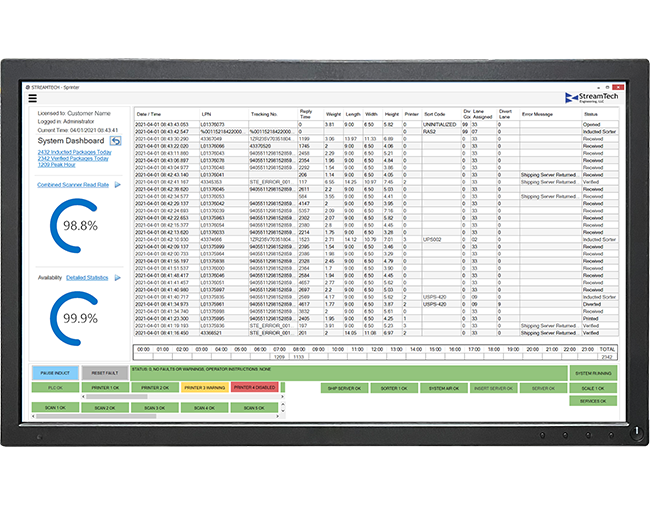

Intelligent Warehouse Control System (WCS) Software

StreamTech bundles our operational and maintenance know-how in the onboard software app that comes on the included Windows Pro 64-bit SSD PC, with rich functionality that supports troubleshooting and enhances uptime. The software easily integrates with rules-based multi-carrier systems or direct carrier interface.

- Extensive troubleshooting built-in to system.

- Smart Filtering of Label Files.

- Expandable for growing customers.

- Rich scan, production, and maintenance statistics with configurable retention.

- Server-based thin client solutions available.

- Backup UPS included to protect PC and SQL database.

- Multi-Level Security, Multi-User Login.

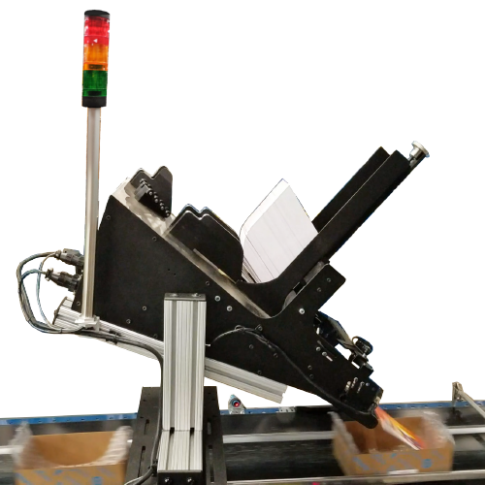

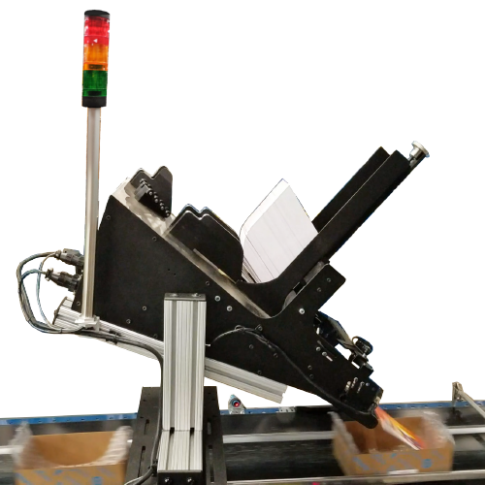

Friction Feeder Features & Options:

Mount in-line over a conveyor or right-angle on a stand for the flexibility to do one-shot applications such as backer cards, top-sheet placement, and collating applications.

- Includes simple-to-use functions: Cycle, Jog, Error Light, Stop, Reset, and Continuous Run Mode.

- Easily mount an ink-jet head or camera directly to the discharge of the feeder for a simple turn-key solution.

- Built-in miss, jam, and timeout detection (with fault output interface) provide valuable features.

Friction Feeder Features & Options:

Mount in-line over a conveyor or right-angle on a stand for the flexibility to do one-shot applications such as backer cards, top-sheet placement, and collating applications.

- Includes simple-to-use functions: Cycle, Jog, Error Light, Stop, Reset, and Continuous Run Mode.

- Easily mount an ink-jet head or camera directly to the discharge of the feeder for a simple turn-key solution.

- Built-in miss, jam, and timeout detection (with fault output interface) provide valuable features.