Built for Entrepreneurs.

So you can get back to running your business.

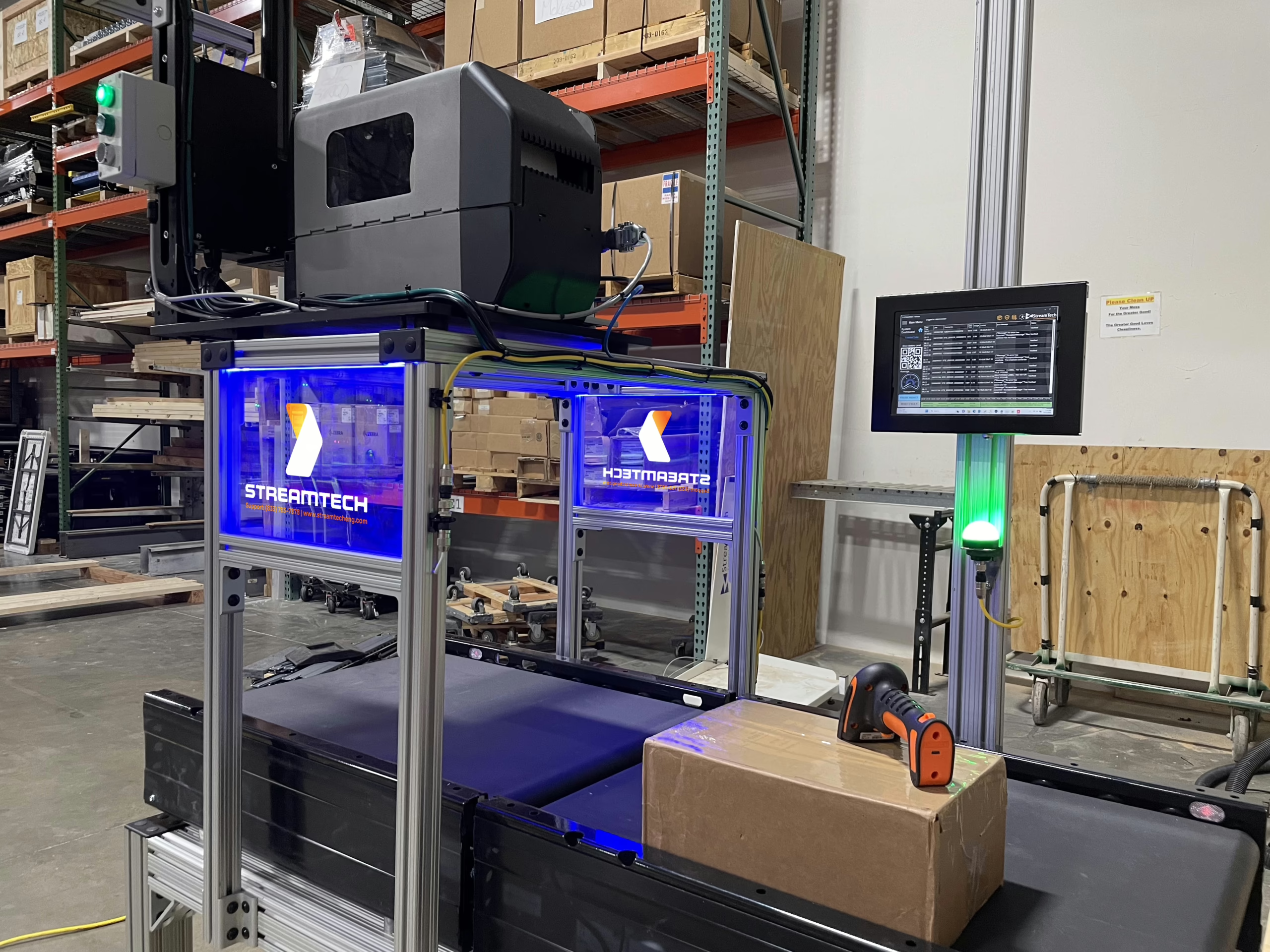

The Spark™ automated shipping system was designed with simplicity in mind, offering an easy-to-deploy solution for operations not yet ready for large-scale warehouse automation. With no installation or assembly required, the system comes pre-configured — just entered your account credentials to get started.

Spark™ automatically weighs, dimensions, labels, and verifies orders once the packing slip is scanned, logging shipping status and capturing all package data for seamless tracking and reporting.

High Throughput, Low Costs

At around 600 cartons per hour, Spark™ is the perfect semi-automatic starting point for a new, growing e-commerce business, at the cost of approximately one FTE salary.

Fast Startup, in Minutes

StreamTech’s software team will pre-integrate our WCS into your multi-carrier software of choice. All you have left is to plug the system in to a standard outlet, and start scanning orders.

Easy to Operate

Just scan a packing slip, place in box, seal carton, then place it on the conveyor. The system does the rest.

Step by Step: How Spark™ Works

The Spark is a simple, compact solution that transforms manual packing stations into automated shipping system hubs. By integrating weighing, dimensioning, labeling, and verification in one streamlined process, Spark™ helps your team improve speed, accuracy, and efficiency — without reworking your entire packing line.

Want to see it in action? Watch the video to see how the Spark works step by step, and discover how easy it is to bring automation right to you pack table.

Spark Specifications

| Type | Specification |

|---|---|

| Max Package | 24″ L x 20″ W x 20″ H, 100LBS |

| Min Package | 7″ L x 5″ W x 0.5″ H, 0LBS |

| Throughput | ~10 CPM (estimate based on operator load rate |

| Package Types | boxes, padded mailers, bags (flat bottom, not over-filled) |

| System Footprint | 5 ft L x 2.5 ft W x 8 ft H |

| Electrical | 120 V standard plug, 15 AMP |

| Labeler | 1000 labels per roll, 4×6 label |

| Scale Accuracy | 0.10LBS (plus or minus 2 sigma) |

| Dimensioner Accuracy | 0.50 inches |

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields