Reduce Labor Costs

Do more—with less manual effort.

Smart Automation That Cuts Costs, Not Corners

Labor is often the most expensive part of fulfillment—but it doesn’t have to be your biggest bottleneck. By automating repetitive, manual tasks like picking, packing, labeling, and sortation, StreamTech helps you operate more efficiently and reduce your reliance on temporary or hard-to-find labor.

Our systems are designed to lower costs while increasing accuracy, throughput, and consistency—helping you stay competitive even as labor markets fluctuate.

Why Labor Costs Matter

Labor is Your Biggest Line Item

In most fulfillment operations, labor accounts for the majority of operational expenses. Reducing labor costs—even slightly—can have an outsized impact on margins and scalability.

The Payoff:

- Immediate savings per order

- Reduced reliance on seasonal/temp labor

- Higher ROI on automation investments

Eliminate Redundant Touches

Manual tasks like walking, scanning, sorting, and packing often involve multiple unnecessary steps. Streamlining workflows reduces labor costs and wasted motion.

The Payoff:

- Fewer labor hours per unit shipped

- Less fatigue and fewer errors

- More productive teams with less burnout

Automate Where it Counts

You don’t need to automate everything—just the right things. Focusing automation on repetitive, low-value tasks frees up your people for more strategic or skilled roles.

The Payoff:

- Lower cost per touchpoint

- Smarter stang strategies

- Reduced turnover in high-churn roles

Control Costs without Cutting Corners

Reducing labor costs doesn’t mean compromising quality. When done through smart automation, you get consistency, speed, and accuracy—while keeping budgets in check.

The Payoff:

- Stable service levels at lower costs

- Fewer errors, returns, and rework

- Sustainable margins as you grow

Lower Labor, Higher Output

Automated Scan & Ship

Replace multi-step manual processes with integrated scan, weigh, dimension, and label systems that operate with minimal oversight.

Smart Pack Automation

Reduce box-building and sealing labor with automated erectors, tapers, and right-size packing systems.

Sortation Systems

Move away from labor-heavy sortation by automating routing based on carrier, zone, etc. with high-speed diverters.

Pick Assistance Tools

Minimize training time and improve speed with scan-to-pick, pick-to-light, and WCS-driven guidance.

Integrated Software

Our WCS platform coordinates hardware and data flow, eliminating the need for manual reconciliation or rework.

Flexible Modularity

Scale your system to match volume—reducing the need to ramp up labor during peak seasons or sudden surges.

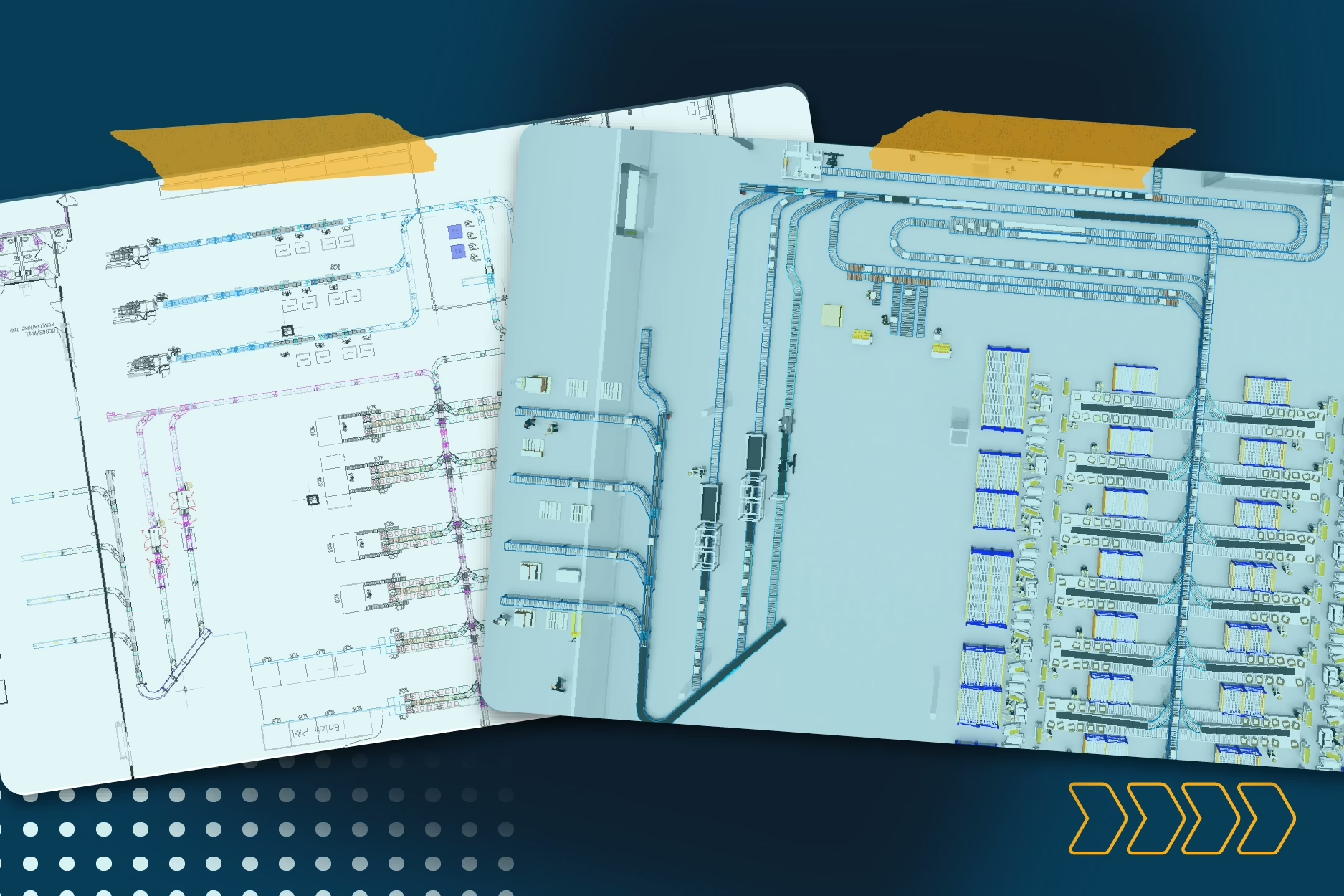

Your Smart Warehouse Starts Here

Partner with StreamTech to design a warehouse automation system that reduces manual labor, increases efficiency, and lowers operational costs. Share your needs—we’ll build a solution that works smarter, not harder.

Increase Pick Accuracy & Speed

Reduce the amount of labor, training time, and errors in picking.

For 3PLs juggling high order volumes and diverse SKUs, Pick to Light streamlines fulfillment. It boosts pick speed, reduces errors, and simplifies training—helping you meet tight SLAs with confidence and consistency.

What if Your Orders Sorted Themselves

Sorting is the final handoff—and a critical one.

Whether you’re routing by carrier, zone, or order type, automation brings speed and certainty to every outbound package. Reduce misroutes, reclaim labor, and keep your operation flowing all the way to the dock.

Add the Personal Touch—Automatically

Custom inserts, gift notes, and branded collateral made easy.

Whether it’s seasonal inserts, brand postcards, care instructions, or gift messages, fulfillment demands more than just fast packing. Automating document and insert handling ensures every order feels intentional and accurate—without slowing down your operation.

The Pack Process is Critical to Successful Fulfillment

Get the packaging right, every time.

Many solutions are available to both assemble the box, as well as verify the proper packaging – checkweigh or dimension, to ensure consistency and accuracy every time.

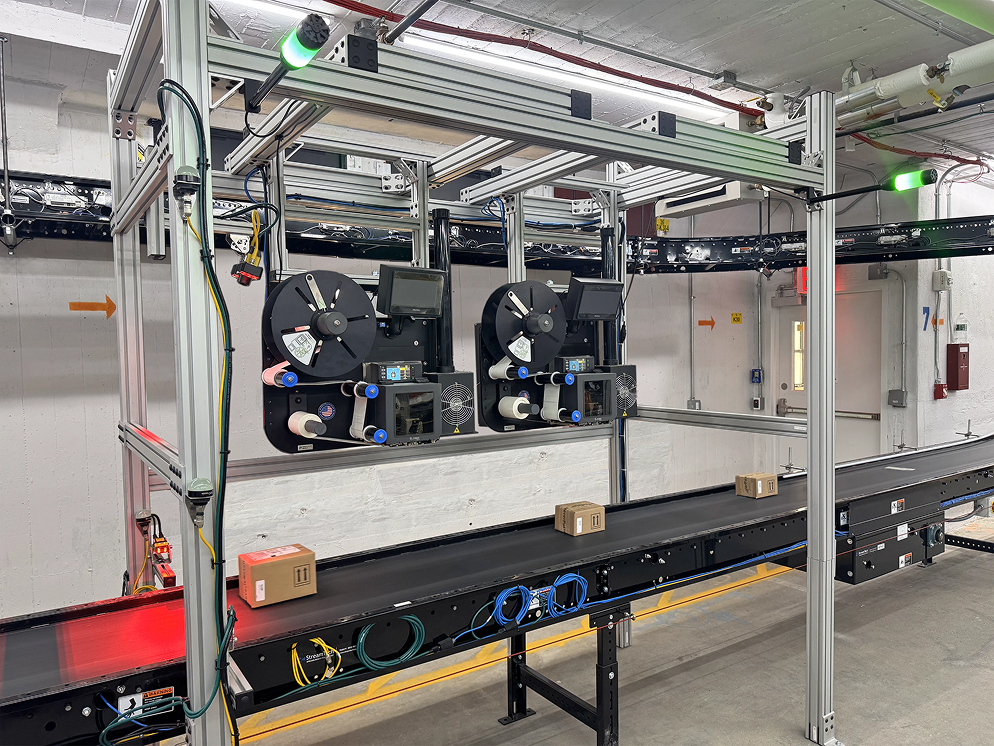

Automate Dimensions, Weight and Shipping Labeling

Own Your Data—Let Your Software Handle Rate Shopping

With a full end-of-line shipping automation system, you can gather weights and dimensions in motion, rate shop them with your multi-carrier TMS software, and then put the right label on every package. These systems can operate starting at 15 CPM, and scale up easily from there.

Software Integration Helps You Keep Your Clients Informed

Light WCS Software Delivers Real-Time Order Data

StreamTech’s WCS software handles orders as they are processed through your warehouse, and integrates seamlessly in real-time with your order databases. Allowing your existing software systems to handle inventory, manage orders, and share the data with you customers as you see fit.

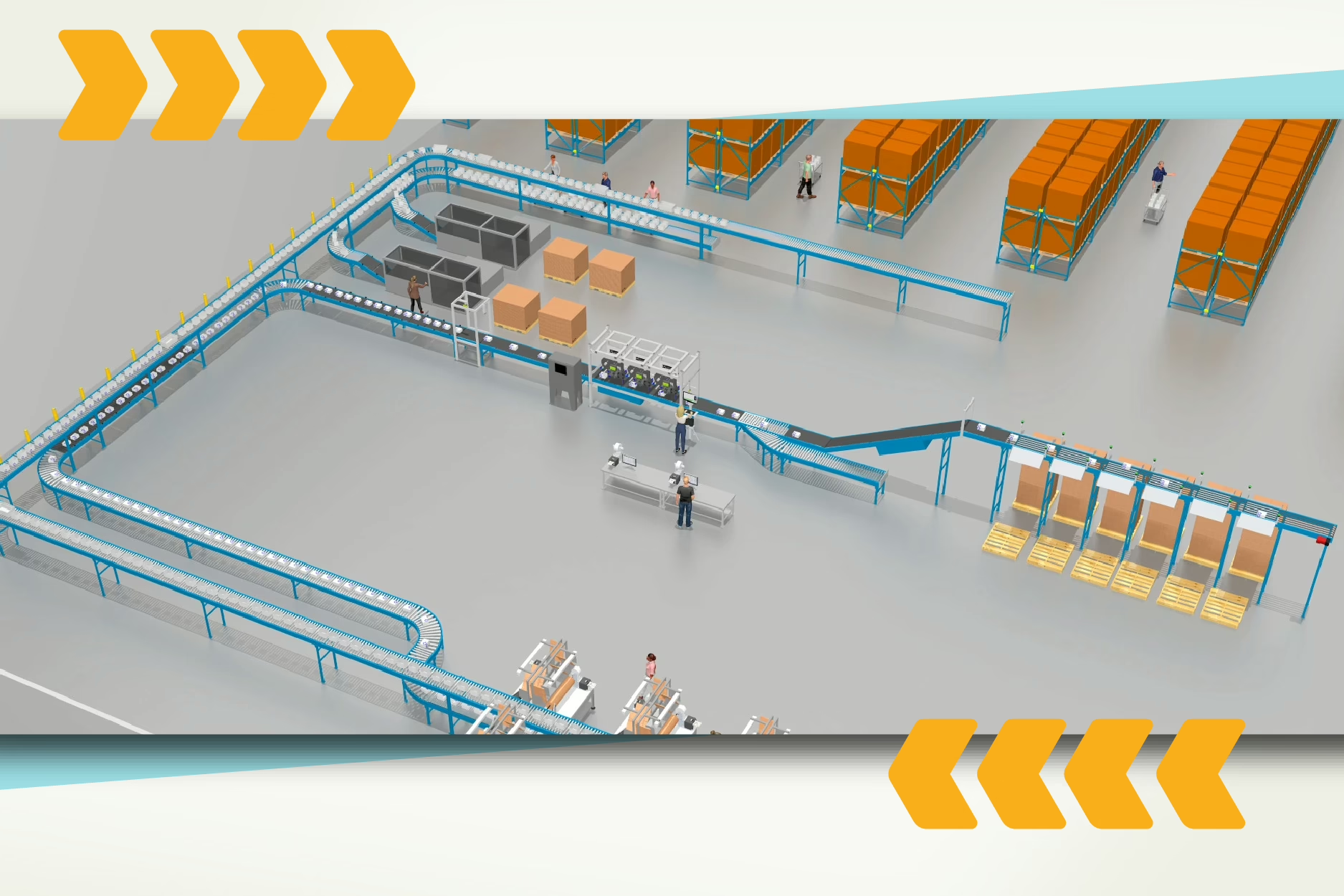

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

What our customers say

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

Will automation replace our warehouse staff entirely?

Not at all. Our goal is to complement your workforce, not eliminate it. Automation takes on the repetitive, time-consuming tasks that slow teams down. Your staff can then focus on quality control, exception handling, and strategic roles that drive growth and reduce labor costs.

We’re struggling to hire and retain warehouse staff. Can automation help?

Yes—significantly. Automation reduces your dependency on temporary or seasonal labor and helps stabilize operations when staffing is inconsistent. It also improves employee retention by removing physically demanding or monotonous tasks.

Can your systems help us reduce overtime and shift coverage needs?

Yes, by increasing throughput and operational efficiency, automation reduces the need for overtime, multiple shifts, or weekend staffing—helping you manage and reduce labor costs more predictably and sustainably.

What if we don’t have the budget for full automation right away?

No problem. We offer modular solutions that can be implemented in phases. You can start with one area—like pack automation or label application—and scale your system as budget and demand allow.

Our systems are designed to scale. During high-volume seasons, automation allows you to fulfill more orders without adding to your labor pool, helping you handle spikes with confidence while reducing labor costs.

Many clients start seeing ROI within the first 12–18 months, depending on the size of the system and throughput. Reduced labor costs, fewer errors, and increased productivity all contribute to faster payback timelines.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields