Visually Verify & Log Orders

Image capture of every order – logged to the unique LPN.

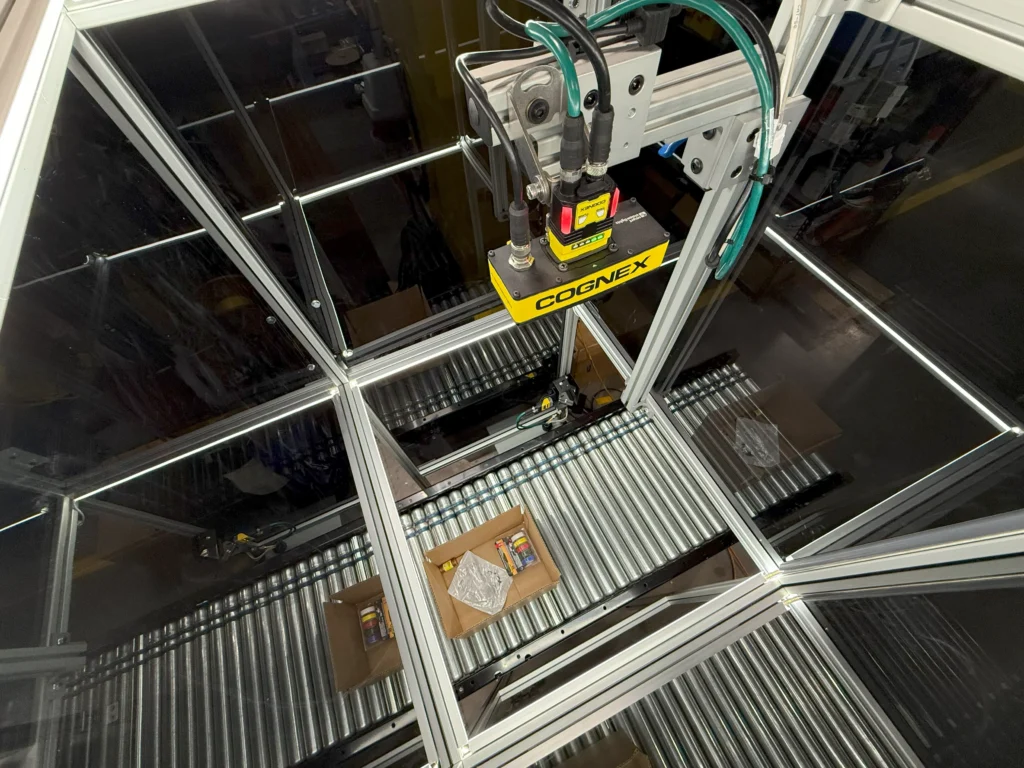

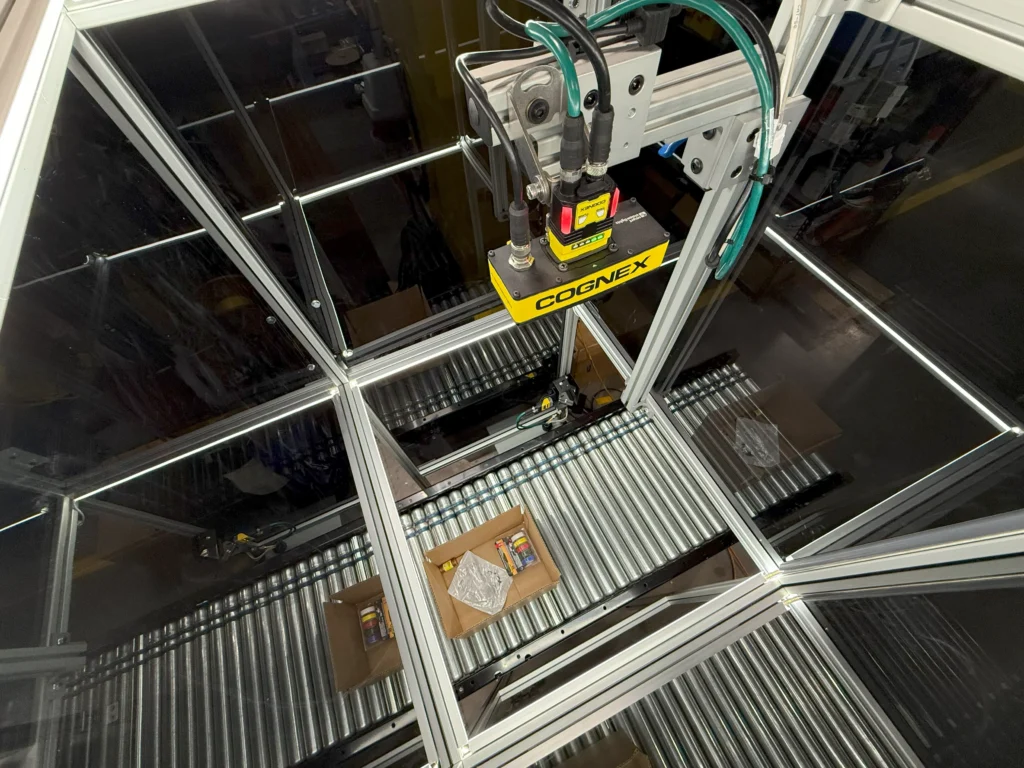

The StreamTech PackSight™ imaging system was designed to give warehouse operators and ecommerce companies the power of having a full resolution image, showing the contents of each order, easily searchable by order ID (LPN).

Here’s How the PackSight™ Works

Packing errors, damage claims, and customer complaints can all create costly downstream issues. PackSight was built to give fulfillment teams the visibility and evidence they need to track what was packed—and prove it. By capturing a high-resolution image of each outbound carton and tying it to the order ID, PackSight brings a new level of accountability to your outbound process.

Whether you’re auditing performance, handling service tickets, or validating compliance, having a searchable visual record makes it easy to trace and resolve issues in seconds. Here’s how the system works:

Features & Benefits

Customer Service Insights

This technology provides rich data to your customer service teams. In the event of a customer complaint about a missed item within their order, manages can search the LPN database to find the image and verify whether it was picked correctly.

Carrier Accountability

With direct images of each outgoing package and its contents as they leave the warehouse, order discrepancies can be tracked down to carrier responsibility.

Internal Pick & Pack Auditing

With image capture technology and (future) machine vision, warehouse managers can track the accuracy of each of the employees handling the pick and pack process.

Closed Box Imaging

Capture images at key stages in the fulfillment process, including case sealer performance, label verification, and post-sort imaging to support both carrier and recipient damage claims. Future machine vision capabilities will further enhance operations by ensuring proper carton branding and compliance.

PackSight Specifications

| Designed to install over any existing conveyor |

| Self-triggering and reporting—no control system integration required |

| Height-adjustable camera for application-specific tuning |

| Captures both open and sealed cartons |

| Supports carton sizes up to 30″ L x 22″ W x 18″ H |

| Images saved by barcode (LPN) for easy search and retrieval |

| Onboard storage capacity for up to 30 million images |

| Images resolution: 1.6 MP |

| Single-lens system with integrated lighting |

| Requires 1x 110V power and 1x network connection |

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields