Pack Automation

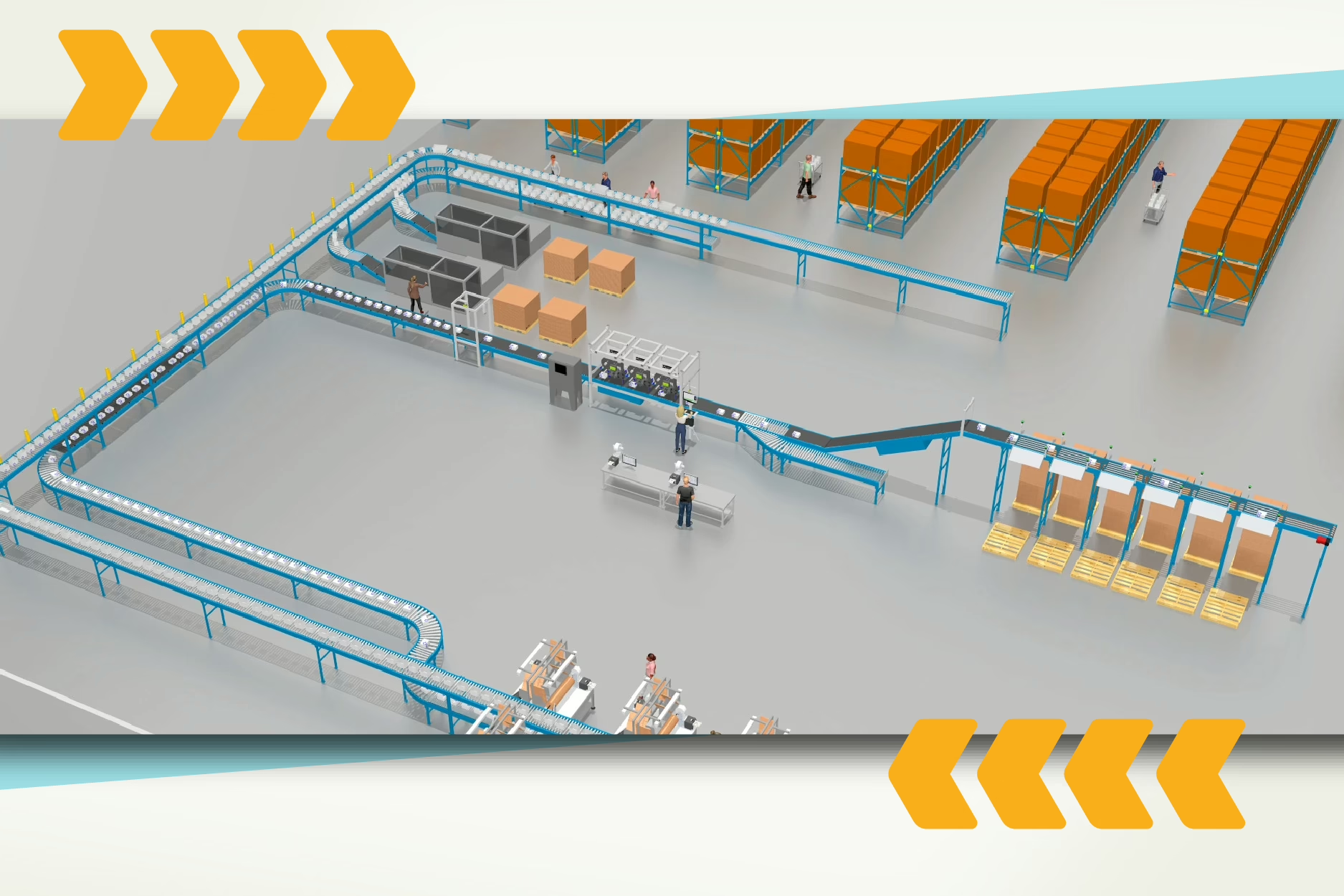

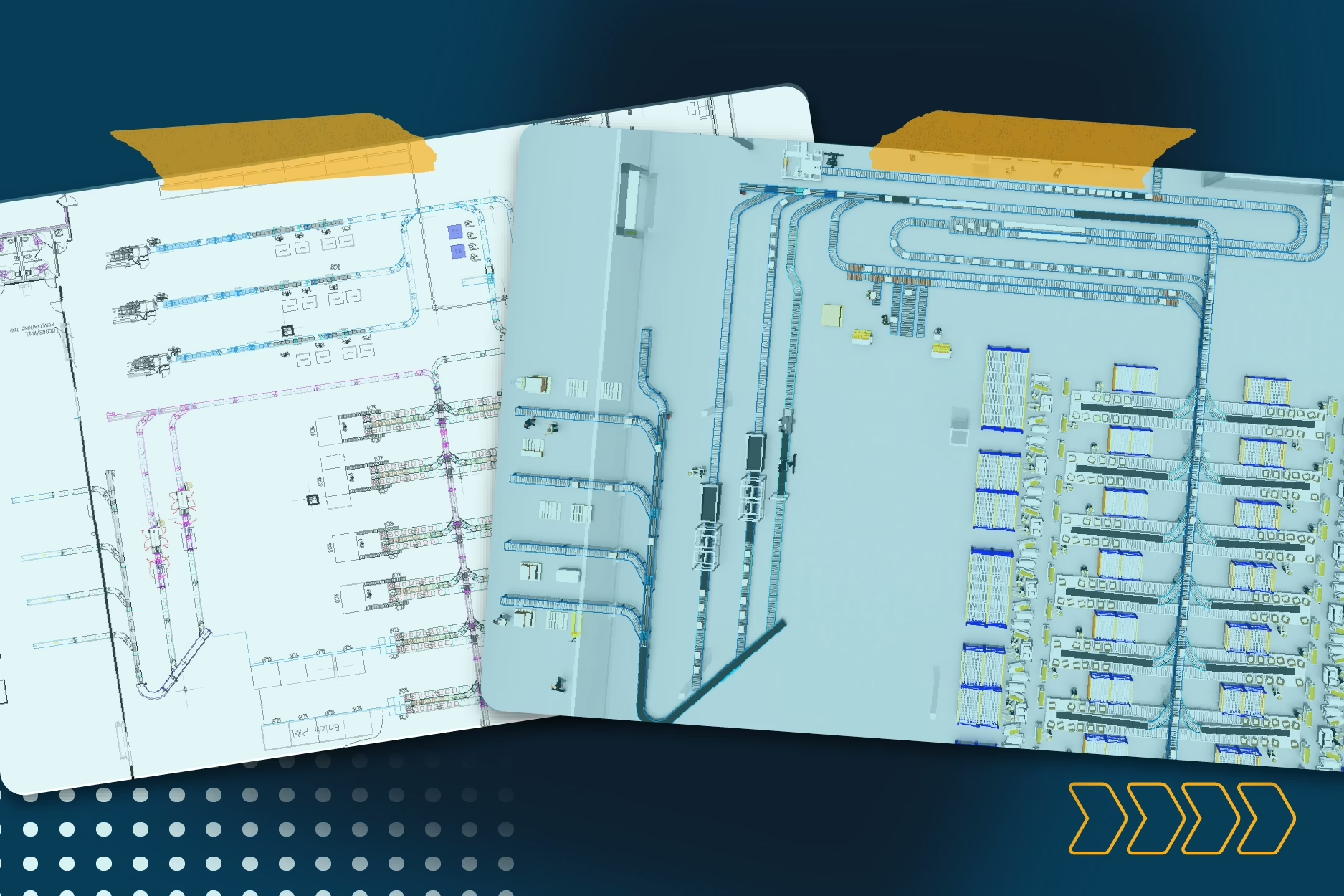

Integrate your packaging equipment with the rest of the end of line automation.

Warehouse Pack Automation

Where packing slows you down, automation speeds you up.

Packing is more than just the space between picking and shipping—it’s where efficiency gains are won or lost. For high-growth fulfillment operations, manual taping and box building slow you down, waste materials, and tie up labor.

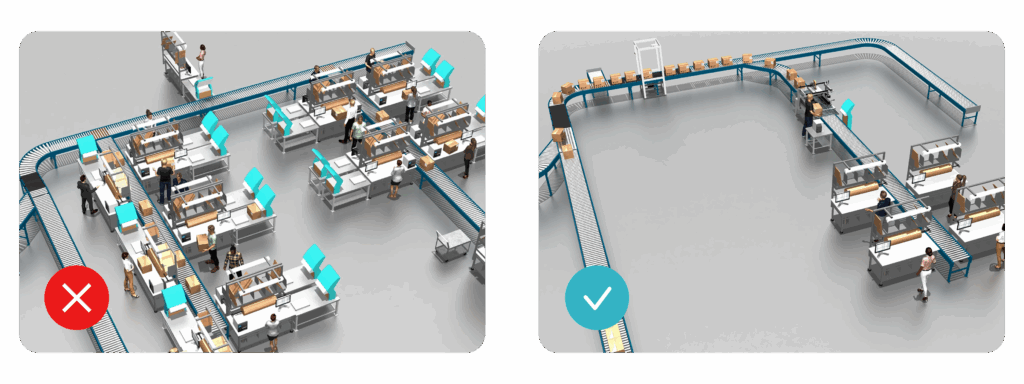

Instead of having duplicate equipment at each pack station, machines that build boxes on demand, or centralized tapers and void fill can take many of the pack tasks away from the tables. Coupling these packaging solutions with end-of-line shipping automation will streamline and reduce the amount of manual touches required at each pack station.

The Pack Process Does Not Have to Be Your Bottleneck.

Improve Order Accuracy

By ensuring cartons are built correctly and sealed consistently, automation minimizes the risk of missed or mispacked items. With PackSight™ capturing every step, you gain traceability and confidence in your outbound accuracy.

Reduce or Re-Allocate Labor

Automated case erectors and tapers take over repetitive, labor-intensive steps—like box forming and taping—freeing up your team for more strategic tasks. It’s an efficient way to do more with fewer hands on deck.

Increase Throughput and Speed of Operation

Automating the physical packing process significantly reduces bottlenecks. With faster carton creation and sealing, your operation can keep pace with high order volumes and meet tight shipping deadlines.

Improve Customer Satisfaction

Properly-constructed, right-sized cartons reduce damage in transit and improve the customer’s unboxing experience. Consistent brand presentation and fewer errors lead to better reviews, fewer returns, and increased loyalty.

Reduce Material Waste

Right-sizing cartons and eliminating manual overpacking results in fewer oversized boxes and less void fill. That translates to cost savings, a smaller shipping footprint, and progress toward your sustainability goals.

Seamlessly Integrate with PackSight

PackSight™ ties together every step of your packing process—coordinating machines, collecting data, and giving you complete operational oversight. From real-time alerts to historical performance, it’s your digital command center.

Smart Pack Automation Solutions for Faster Fulfillment

Pack automation systems help eliminate bottlenecks between picking and shipping. We can integrate I/O with your packaging technologies to improve accuracy, and speed up fulfillment so you can hit carrier cutoffs and keep customers happy.

Semi-Automated Carton Erectors

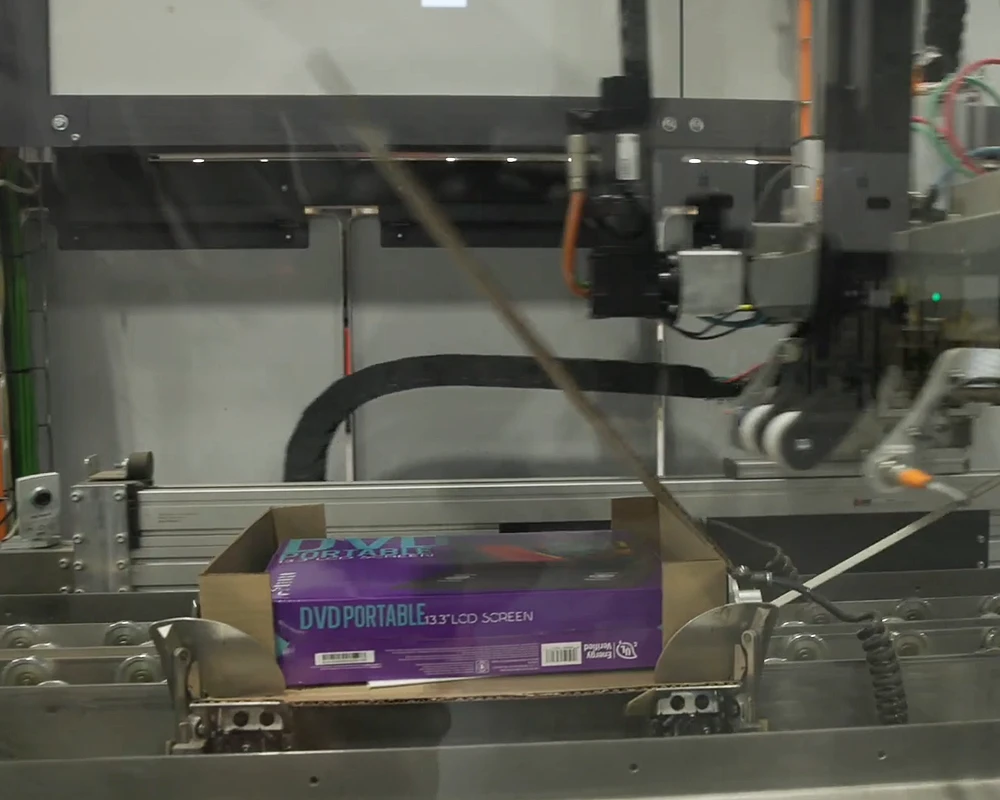

Random Robotic Carton Erector

Semi-Automated Carton Closure

Bagging

Tray Erector Integration

Random Case Erector Integration

Featured StreamTech

Products

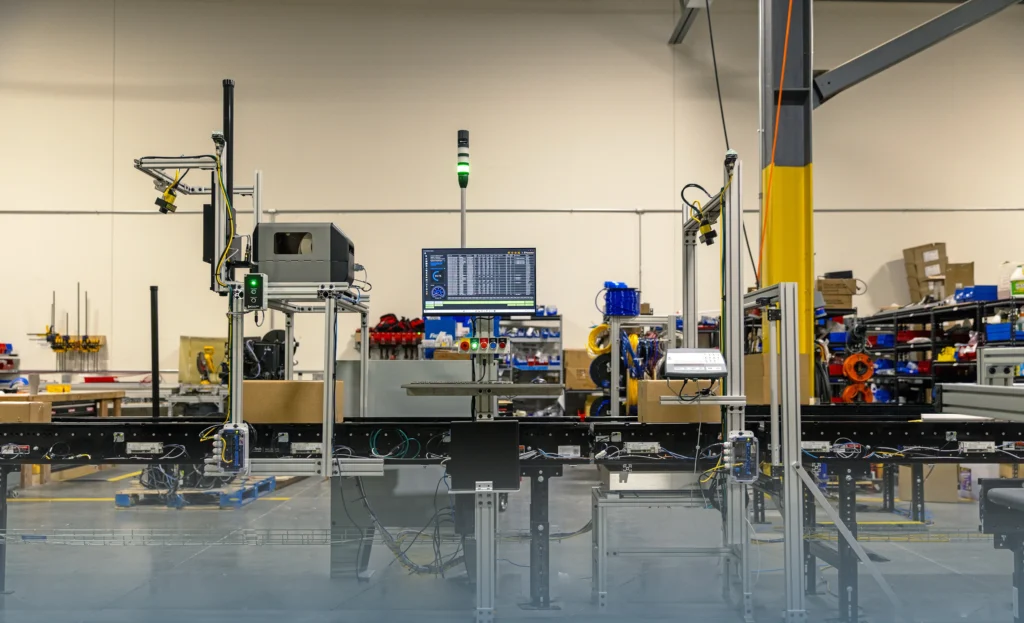

Sprinter™ Pre-Engineered Fully Automated Shipping System

An all-in-one scan, weigh, dimension, print and apply shipping system.

The Sprinter™ can process approximately 600 to 1,000 cartons per hour, uses standard components, an accumulation conveyor for accommodating manifest response time, and is pre-engineered for fast installation. It is an excellent first step into automation.

PackSight™

Image capture provides accountability of the pack process.

PackSight™ photographs every outbound carton and links it to the order’s barcode (LPN). Whether open or sealed, each box is captured as it moves down the conveyor, providing visual proof of packing. Images are easily searchable, and help customer service quickly resolve claims, verify accuracy, and trace issues.

We’ll Collaborate with Your Packaging Reps

Whether you already have packaging systems in place or work with a preferred supplier, StreamTech Engineering is ready to collaborate. We integrate with existing packaging equipment or can allow you to source your own. We focus on smart fulfillment automation that works with what you have, not against it.

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

What packing tasks can StreamTech automate?

StreamTech’s automation systems can integrate with carton creation (case erecting), right-sizing, sealing, bagging, and robotic case erectors. We incorporate I/O that allows these types of equipment to communicate back and forth between our control panel, enabling the rest of the automation to work seamlessly – to handle tasks like conveyance, labeling, scanning, sorting and more.

How does PackSight help improve accuracy and accountability?

PackSight™ is a real-time image capture and tracking system that photographs each order (open or sealed) as it moves down the line. It links images to the order ID (LPN), giving your team searchable proof of packing accuracy and helping quickly resolve claims or errors.

Is pack automation only for large operations?

Not at all. StreamTech offers scalable solutions—from entry-level tapers to fully automated systems—that grow with your business. Whether you’re packing a few hundred or thousands of orders a day, automation helps you reduce labor, improve consistency, and speed up fulfillment.

Can these systems integrate with our current software and workflows?

Yes. StreamTech’s pack automation—including PackSight™—seamlessly integrates with WMS, ERP, and multi-carrier systems. This ensures smooth data exchange, visibility into performance, and minimal disruption to your existing processes.

Right-sizing cartons and eliminating manual overpacking leads to fewer oversized boxes and less void fill. This reduces material costs, minimizes dimensional weight charges, and supports your sustainability goals—while still protecting every shipment.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields