How To Increase Throughput With Fulfillment Automation

Speed up your warehouse fulfillment to grow with demand.

Move faster. Fulfill smarter. Grow without breaking a sweat.

Throughput is the heartbeat of fulfillment—the speed and efficiency with which your warehouse turns orders into outbound shipments. Whether you’re preparing for peak season, onboarding new retail partners, or responding to viral demand, increased throughput is key to operational agility.

Why Throughput Matters

Scale with Confidence

As order volumes grow—whether from peak seasons, flash sales, or viral demand—your fulfillment operation needs to keep pace. High throughput ensures you can scale withoutadded chaos or cost.

The Payoff:

- Smooth peak season performance

- No missed SLAs due to volume spikes

- Growth without adding headcount

Power New Business Opportunities

Expanding into new markets or channels brings new complexity. Throughput gives you the operational headroom to onboard major accounts, new SKUs, or bigger order sizes—without slowing down.

The Payoff:

- Faster onboarding of retail/wholesale partners

- Flexibility to handle new fulfillment models

- Competitive service levels from day one

Turn Metrics into Momentum

Tracking throughput metrics like picks per hour, cartons per minute, and orders per day helps you benchmark performance—and drive continuous improvement across the floor.

The Payoff:

- Actionable KPIs tied to productivity

- Visibility for labor planning and resource

- Data to guide operational decisions allocation

Speed Without Sacrificing Quality

Throughput isn’t just about going faster—it’s about doing more, better. When speed is paired with precision, you get efficient fulfillment that still delivers on customer expectations.

The Payoff:

- Higher order output per shift

- Maintained or improved accuracy

- Reduced overtime and labor strain

Proven Throughput Strategies

Minimize Touches

Reduce human handling wherever possible through automation and smart routing.

Keep Flow Continuous

Leverage conveyors and buffer logic to eliminate dwell time and bottlenecks.

Automate the Repetitive

Deploy box formers, labelers, and doc inserters to speed up outbound lines.

Smarter Picking

From batch picking to Pick-to-Light and G2P, we help your team pick faster with less walking.

Parallel, Not Sequential

Enable simultaneous picking, scanning, and shipping to remove process delays.

Balance the Load

Dynamic zone balancing and order wave management ensure every part of the system is working in sync.

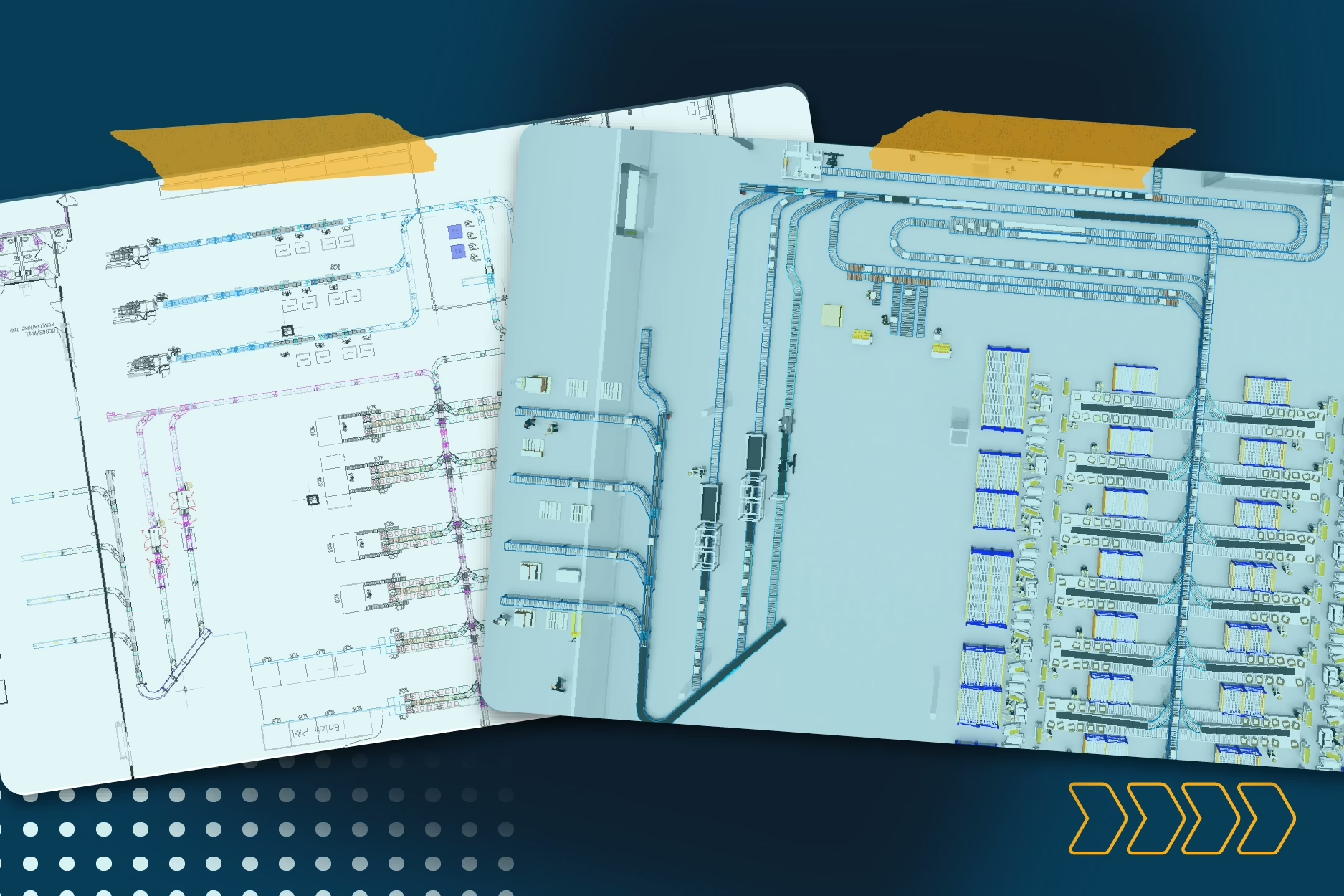

Your Smart Warehouse Starts Here

Looking to boost output without sacrificing quality? Our integrated automation solutions are built to increase throughput, reduce slowdowns, and keep your operations running at peak performance. Tell us what you need, and we’ll make it happen.

Transform Your Picking Strategy

Goods-to-Person picking can revolutionize apparel.

Goods-to-Person robotic picking streamlines apparel fulfillment by delivering items directly to workers, reducing walk time, increasing accuracy, and increasing order throughput. It’s a smart, scalable solution for faster, more efficient picking.

What if Your Orders Sorted Themselves

Sorting is the final handoff—and a critical one.

Whether you’re routing by carrier, zone, or order type, automation brings speed and certainty to every outbound package. Reduce misroutes, reclaim labor, and keep your operation flowing all the way to the dock.

Add the Personal Touch—Automatically

Custom inserts, gift notes, and branded collateral made easy.

Whether it’s seasonal inserts, brand postcards, care instructions, or gift messages, fulfillment demands more than just fast packing. Automating document and insert handling ensures every order feels intentional and accurate—without slowing down your operation.

The Pack Process is Critical to Successful Fulfillment

Get the packaging right, every time.

Many solutions are available to both assemble the box, as well as verify the proper packaging – checkweigh or dimension, to ensure consistency and accuracy every time.

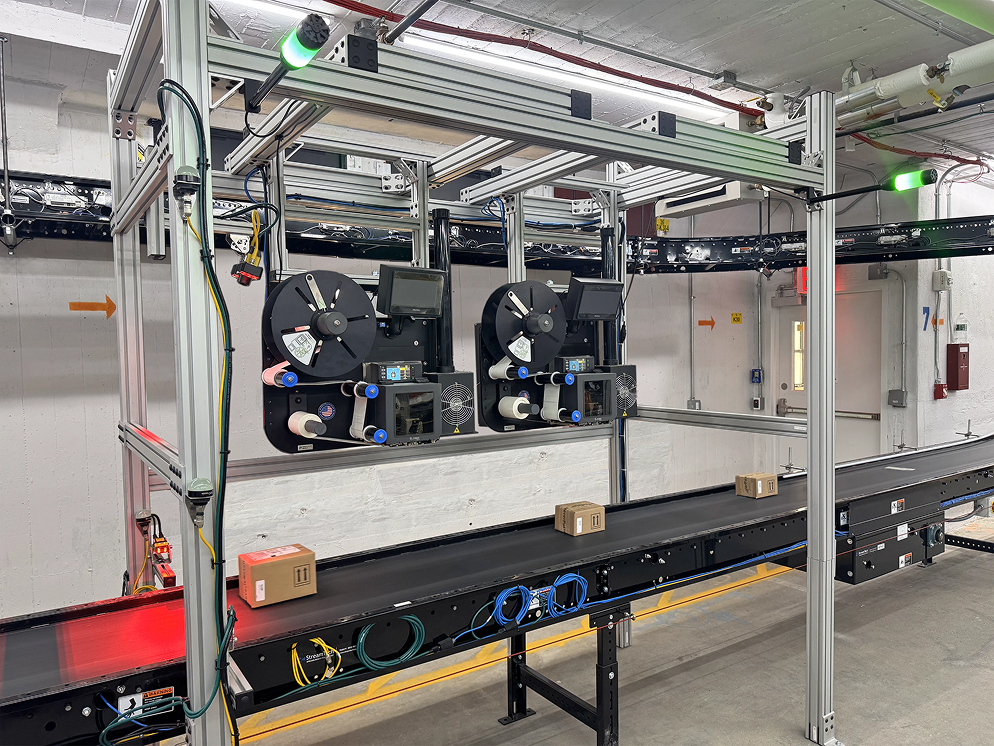

Automate Dimensions, Weight and Shipping Labeling

Own Your Data—Let Your Software Handle Rate Shopping

With a full end-of-line shipping automation system, you can gather weights and dimensions in motion, rate shop them with your multi-carrier TMS software, and then put the right label on every package. These systems can operate starting at 15 CPM, and scale up easily from there.

Software Integration Helps You Keep Your Clients Informed

Light WCS Software Delivers Real-Time Order Data

StreamTech’s WCS software handles orders as they are processed through your warehouse, and integrates seamlessly in real-time with your order databases. Allowing your existing software systems to handle inventory, manage orders, and share the data with you customers as you see fit.

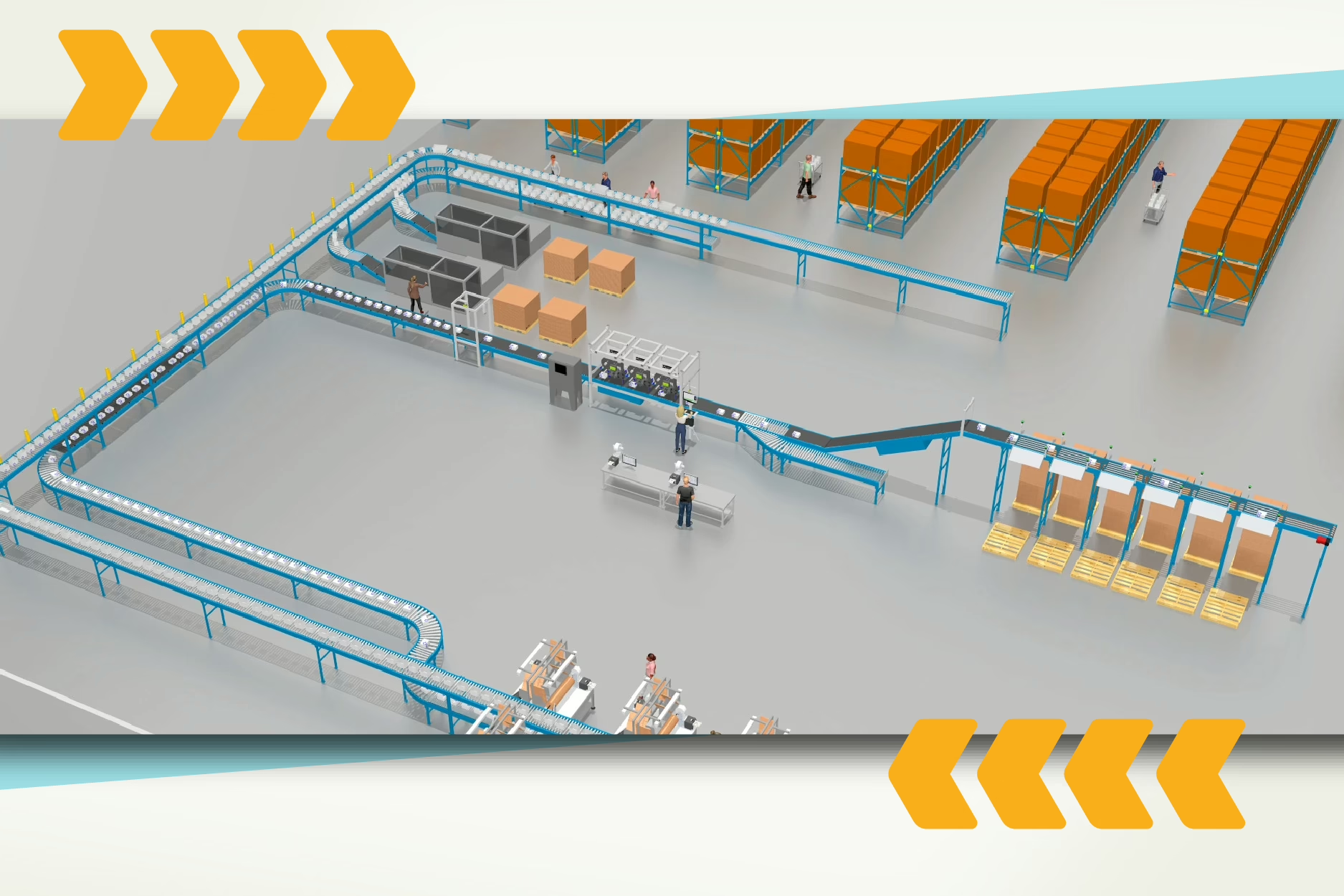

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

What our customers say

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

Can automation help us reduce order cycle times?

Yes. By eliminating delays between fulfillment steps and reducing manual intervention, our systems shrink the time it takes to process and ship each order—helping you meet tighter delivery windows and customer expectations.

We’re hitting a throughput ceiling during peak season—can StreamTech help?

Absolutely. Our solutions are built to scale with demand. Whether you’re preparing for holiday spikes or flash sales, we help you maintain fast, accurate throughput when it matters most—without having to hire or train seasonal staff.

Can we improve throughput without a complete facility overhaul?

Yes. We offer modular solutions that work within your existing layout and processes. Whether you’re upgrading one station or overhauling the whole line, we’ll help you make incremental improvements with high impact.

What if we have a wide range of product sizes and order profiles?

Our systems are designed for flexibility. From flat mailers to bulky items, we configure your automation to handle variable SKUs and order complexities while keeping throughput high.

Implementation timelines vary, but most projects go live within a few months. We’ll work with you to plan a phased rollout that minimizes disruption and delivers ROI quickly.

We track metrics like orders per hour, error rate reduction, labor utilization, and overall system uptime. Our goal is to show measurable improvement in your fulfillment capacity and processing speed.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields