How to Increase Accuracy with Fulfillment Automation

The precision of order fulfillment.

Get every order out right—the first time.

In warehouse fulfillment, accuracy matters. Every mispick, mislabeled package, or inventory discrepancy slows down operations and chips away at customer trust. At StreamTech, we help fulfillment operations increase accuracy across every step—pick, pack, and ship—using smart automation and integrated systems that catch errors before they happen.

Because in the world of e-commerce, getting it right is just as important as getting it out fast.

Why Accuracy Matters

Fewer Errors, Happier Customers

When every order is right the first time, you build trust with customers and reduce costly returns. Accurate picking, packing, and labeling keep your operation smooth—and your brand reputation intact.

The Payoff:

- Fewer returns

- Less rework and waste

- Stronger customer loyalty

Accuracy Enables Growth

The more complex your orders, the more important accuracy becomes. Whether you’re scaling to meet demand or launching into new markets, precision keeps everything running smoothly.

The Payoff:

- Better inventory control

- On-time, correct orders

- Consistent performance at scale

Reduce Operational Costs

Accuracy at the end-of-line—during packing, labeling, and sortation—is critical to meeting SLAs and shipping expectations. Automation ensures consistency where it matters most.

The Payoff:

- Fewer shipping mistakes

- Lower transportation costs

- Higher on-time delivery rates

Accuracy Powers Automation

Automation only works when the data behind it is reliable. From inventory systems to sortation logic, your automated workflows depend on precise inputs. Without accuracy, automation breaks down—turning efficiencies into costly errors.

The Payoff:

- Reliable system performance

- Seamless handoffs between automated steps

- Scalability without sacrificing control

Targeted Automation. Verified Accuracy.

Guided Picking

Eliminate guesswork with scan-to-pick or pick-to-light systems that confirm SKU and quantity before it leaves the shelf.

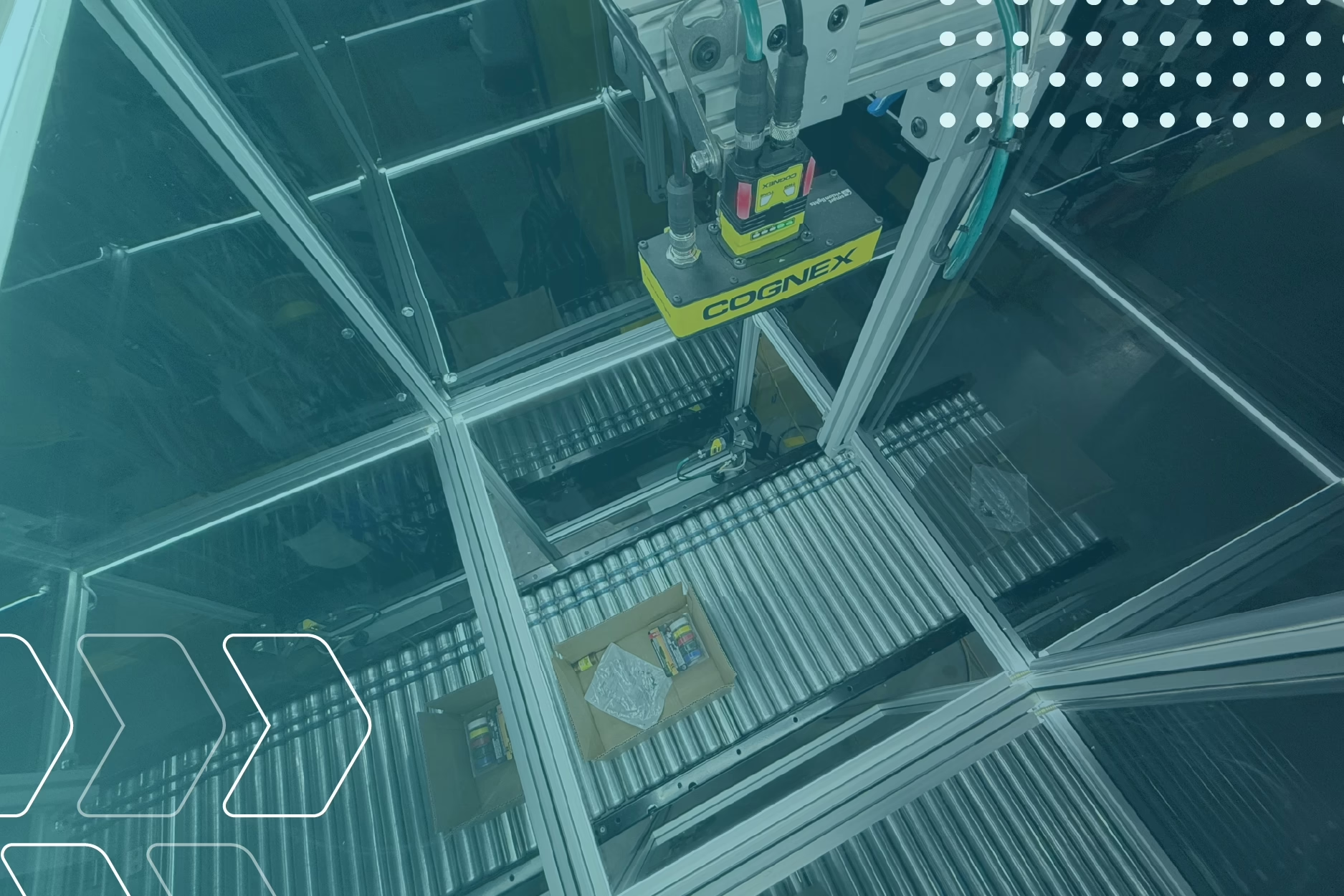

Pack Verification

Vision-based tools like PackSight™ confirm order contents before the box is sealed, reducing returns and improving customer satisfaction.

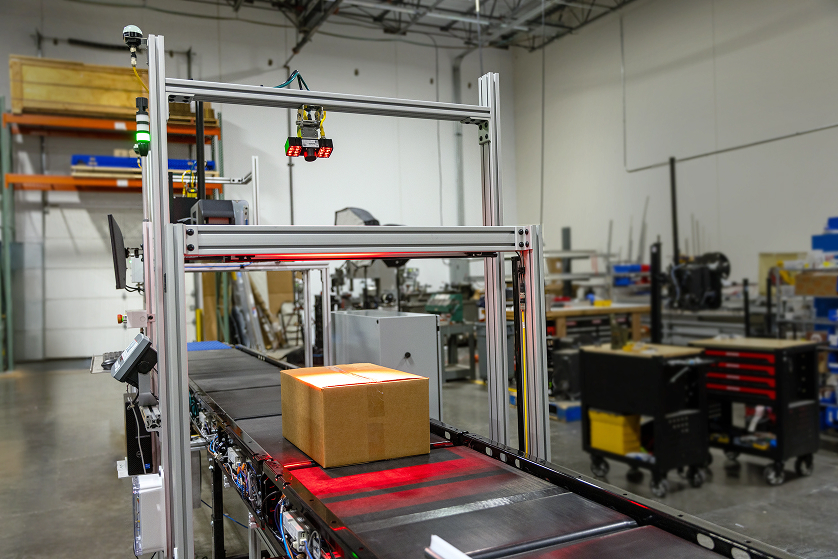

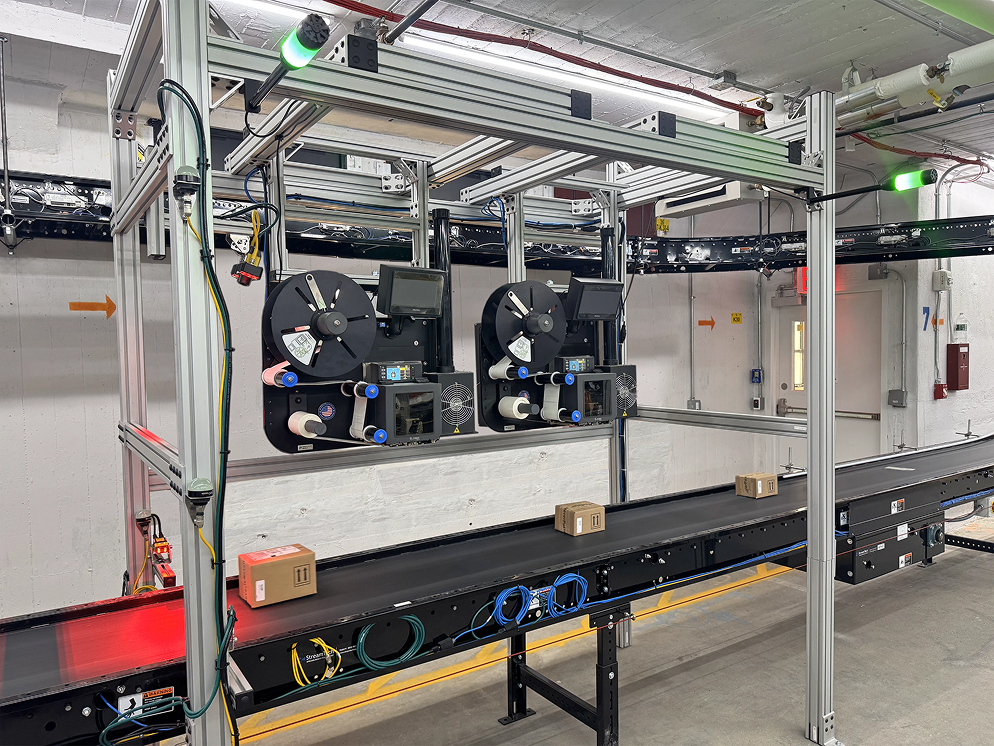

Automated Labeling

Print-and-apply systems verify each label and apply it correctly—no manual data entry, no misroutes.

Inventory Control

Accurate fulfillment starts with accurate stock. Our systems integrate real-time scanning and cycle count validation for tighter inventory control.

Integrated WCS

Sync order data across your systems with StreamTech’s Warehouse Control Software—minimizing human input and standardizing accuracy.

Exception Handling & Alerts

Automated systems flag irregularities in real time—such as weight mismatches, unreadable barcodes, or missing data—so your team can correct issues before they turn into costly mistakes.

Your Smart Warehouse Starts Here

Let’s work together to build an automation system that minimizes human error, ensures precise handling, and improves overall order fulfillment accuracy. Tell us what you need, and we’ll engineer the right solution.

Increase Pick Accuracy & Speed

Reduce the amount of labor, training time, and errors in picking.

For 3PLs juggling high order volumes and diverse SKUs, Pick to Light streamlines fulfillment. It boosts pick speed, reduces errors, and simplifies training—helping you meet tight SLAs with confidence and consistency.

What if Your Orders Sorted Themselves

Sorting is the final handoff—and a critical one.

Whether you’re routing by carrier, zone, or order type, automation brings speed and certainty to every outbound package. Reduce misroutes, reclaim labor, and keep your operation flowing all the way to the dock.

Add the Personal Touch—Automatically

Custom inserts, gift notes, and branded collateral made easy.

Whether it’s seasonal inserts, brand postcards, care instructions, or gift messages, fulfillment demands more than just fast packing. Automating document and insert handling ensures every order feels intentional and accurate—without slowing down your operation.

The Pack Process is Critical to Successful Fulfillment

Get the packaging right, every time.

Many solutions are available to both assemble the box, as well as verify the proper packaging – checkweigh or dimension, to ensure consistency and fulfillment accuracy every time.

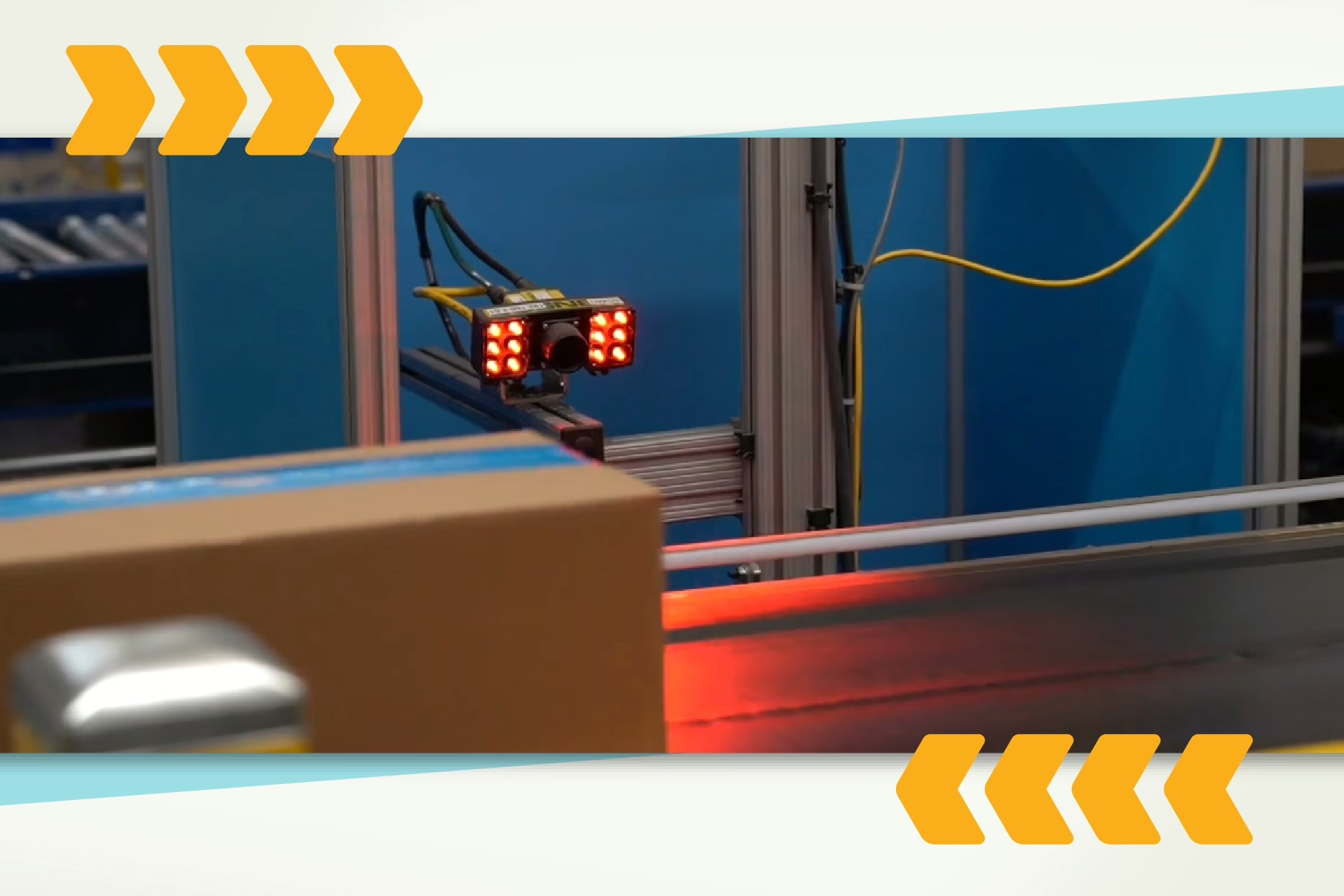

Automate Dimensions, Weight and Shipping Labeling

Own Your Data—Let Your Software Handle Rate Shopping

With a full end-of-line shipping automation system, you can gather weights and dimensions in motion, rate shop them with your multi-carrier TMS software, and then put the right label on every package. These systems can operate starting at 15 CPM, and scale up easily from there.

Software Integration Helps You Keep Your Clients Informed

Light WCS Software Delivers Real-Time Order Data

StreamTech’s WCS software handles orders as they are processed through your warehouse, and integrates seamlessly in real-time with your order databases. Allowing your existing software systems to handle inventory, manage orders, and share the data with you customers as you see fit.

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

What our customers say

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

What types of errors can your system help eliminate?

Our systems are built to prevent mispicks, incorrect pack slips, wrong weights, mismatched SKUs, and duplicate shipments. We help you eliminate costly mistakes that lead to returns, refunds, and customer dissatisfaction.

We already have a WMS—can StreamTech enhance our fulfillment accuracy without replacing it?

Yes. We integrate with most major WMS and OMS platforms, adding smart automation layers that validate and verify fulfillment steps in real-time. You don’t need to overhaul your tech stack—we’ll help make it more accurate and efficient.

How do your systems verify that an order was packed correctly?

We use multiple verification points, including barcode scanning, weight checks, and optional image capture. If the scanned contents don’t match what was ordered—or if the weight is outside expected thresholds—the system flags it before the package moves to shipping.

What if something goes wrong—does the system catch it in real time?

Yes. If there’s a mismatch, missing item, or packaging error, the system alerts the operator immediately and can divert the order for correction. This helps prevent bad shipments from leaving the facility.

Fewer returns, less rework, and improved customer satisfaction all lead to higher profit margins. High fulfillment accuracy also builds customer trust—turning one-time buyers into loyal customers.

Yes. Our systems are built for speed and flexibility. Whether you’re processing hundreds of SKUs or thousands of daily orders, our automation keeps pace while ensuring every step is verified.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields