Goods-to-Person Picking

Bringing Inventory to the Picking Operators

Autonomous picking that looks like magic.

Increase Pick Speed and Accuracy While Increasing Storage Density

Geek+ shelf-to-person picking system uses AMR picking robots to move the inventory shelves and pallets directly to the picking station. This reduces the reliance on manual labor, significantly minimizing errors and accelerating the picking process. Compared to manual picking, automated picking solutions improve efficiency by 2 to 3 times.

The automation provided by this system utilizes AI which allows for continuous operation and improves turnaround times, ultimately leading to higher customer satisfaction through quicker order fulfillment. As a crucial component of modern logistics and supply chain management, this system is essential for businesses aiming to stay competitive in today’s fast-paced market.

Why Goods-to-Person Picking?

Order Optimization & Group Picking

This feature streamlines the picking process by grouping orders with similar items, minimizing travel time and increasing efficiency. It ensures that the most logical and shortest routes are followed, speeding up order fulfillment.

Dynamic Wave Picking Process

Dynamic wave picking allows for the flexible grouping of orders into waves, optimizing the picking schedule based on real-time demands and priorities. This method reduces bottlenecks and maximizes throughput during peak operational times.

Heat Mapping & Placement Recommendations

Heat mapping visualizes high-demand areas within the warehouse, guiding the strategic placement of goods to minimize movement. Placement recommendations are generated to further enhance picking efficiency and reduce labor costs.

Inventory Layout Adjustment

This tool enables dynamic adjustment of the warehouse layout based on changing inventory levels and patterns, optimizing space utilization. Regular adjustments ensure that the layout continuously aligns with current operational needs, boosting overall efficiency.

Inventory Management & Intelligent Tally

Advanced inventory management systems track stock levels in real-time, ensuring accuracy and reducing the risk of overstocking or stockouts. Intelligent tally systems provide precise counting and data analysis, enhancing decision-making capabilities.

Robot/Workstation Task Integration

Robot and workstation task integration seamlessly coordinates activities between automated systems and human workers, optimizing workflow. This integration ensures smooth operations and reduce human error by allowing robots and employees to work in harmony.

RFID Technology Integration

RFID technology enhances tracking and management of inventory by providing instant data on the movement and status of items throughout the warehouse. This integration leads to improved accuracy and speed in inventory control processes.

Customized Options

Customized options allow clients to tailor the automated system to fit specific operational requirements and preferences. This flexibility ensures that each solution perfectly aligns with the unique challenges and goals of different warehouse environments.

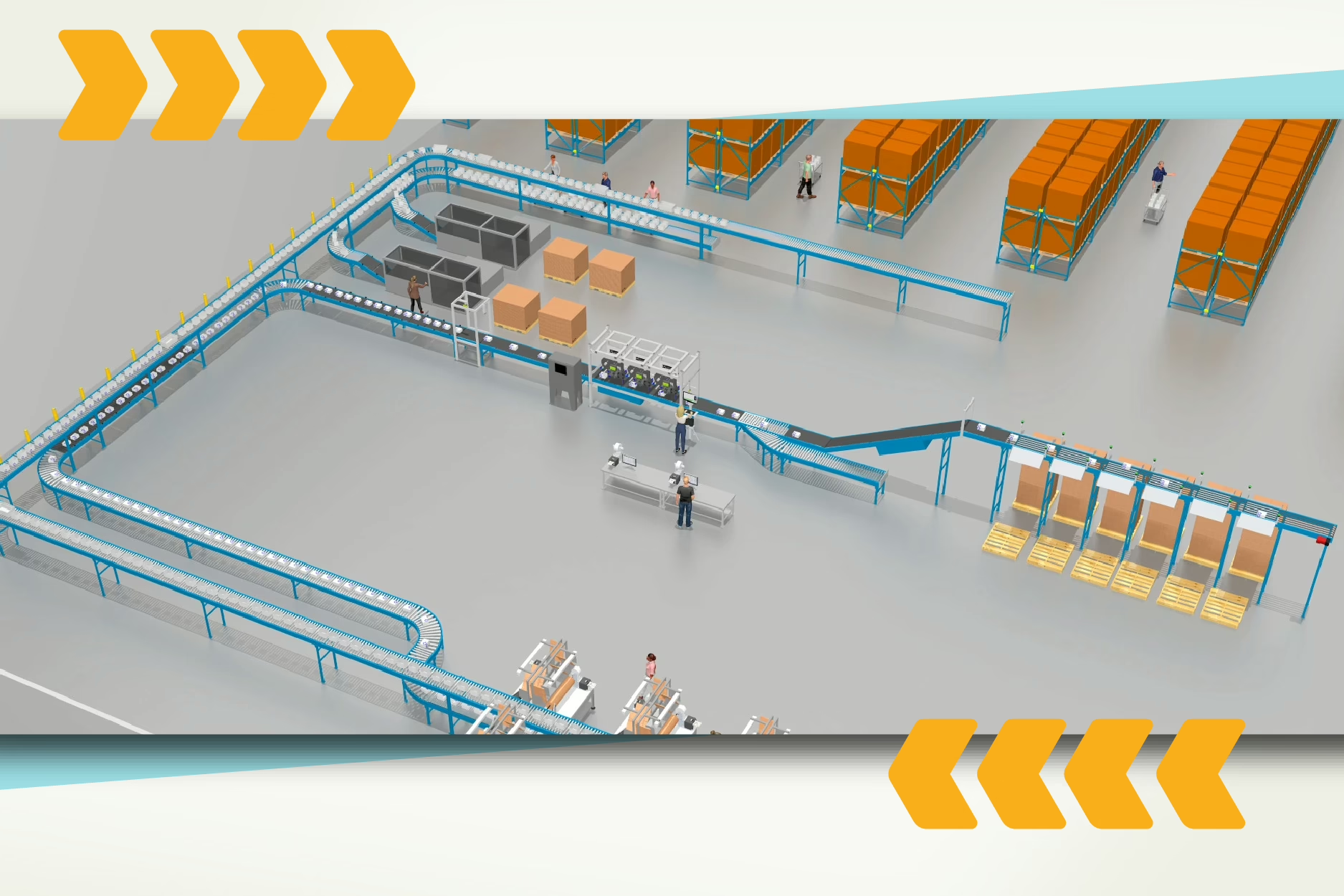

How Goods-to-Person Works

Shelf-to-person picking redefines warehouse efficiency by bringing inventory directly to the operator—cutting down on travel time and boosting productivity. Instead of walking aisles to locate products, workers stay at a central picking station while shelves or mobile racks are automatically delivered to them.

This system increases picking speed, improves order accuracy, and reduces physical strain on employees. With smart software directing the flow, each order moves smoothly from picking to packing—helping operations scale with demand and deliver consistently faster fulfillment.

Proven Results That Move the Needle

From speed to accuracy to labor savings, Geek+ automation solutions deliver measurable results that transform warehouse performance.

60%

Labor Reduction

70%

Floor Space Savings

3-5

Month Implementation

Which Goods-to-Person Technology Fits Your Needs?

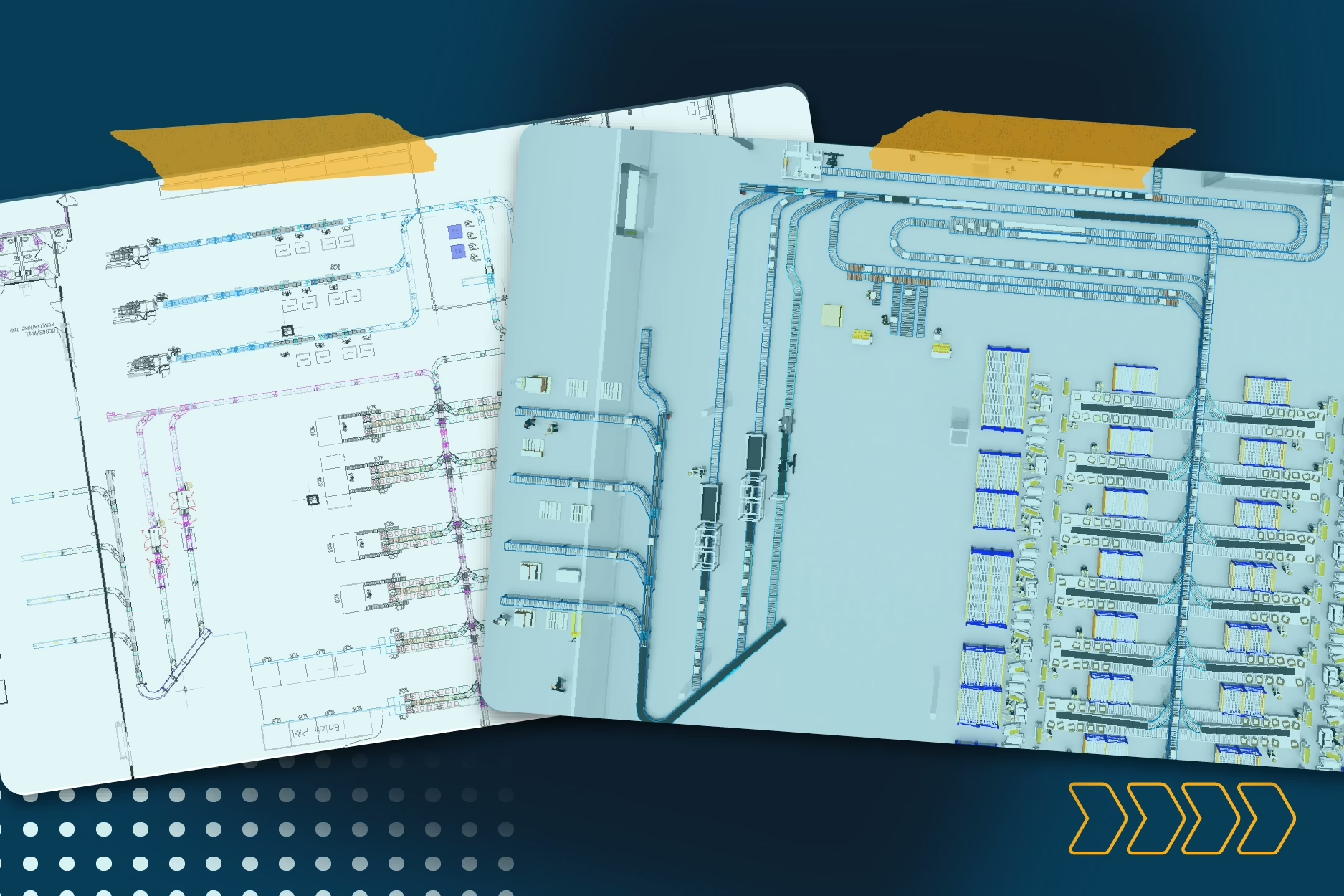

Shelf-to-Person

PopPick

The Geek+ Shelf-to-Person system uses autonomous mobile robots to bring movable shelves directly to ergonomic workstations, eliminating worker travel, boosting picking efficiency by 2–3x, and achieving near-perfect accuracy (99.99%).

Now with an upgraded PopPick variant, the system supports totes, pallets, and large items within a unified workflow, optimizing throughput via high-density storage, dynamic wave picking, heat mapping, and automated slotting – even during off hours. Powered by Geek+’s intelligent Warehouse Execution and Robot Management Systems, it enables rapid scaling, flexible layout reconfiguration, reduced labor intensity, and fast ROI for industries such as e-commerce, 3PL, retail, and manufacturing.

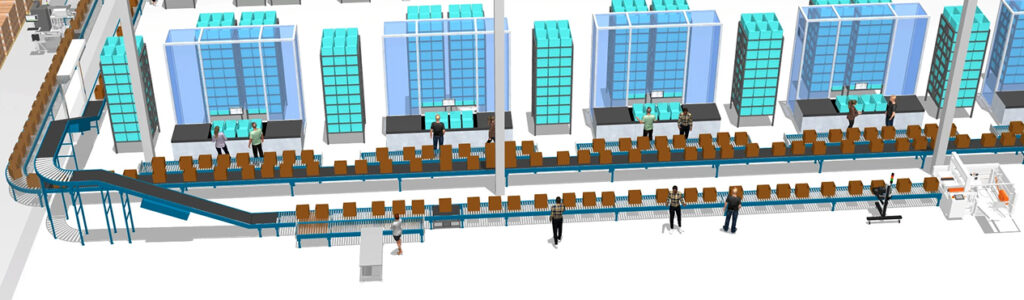

Tote-to-Person

RoboShuttle

RoboShuttle, Geek+’s award-winning Tote-to-Person system, delivers high picking efficiency, dense storage, and narrow aisle capability. Its flexible design replaces fixed equipment, using the compact P400 robot to travel beneath racks, maximize aisle space, and maintain nonstop workflows. It works with the P40, caches high-demand SKUs on lower shelves, and auto-optimizes storage during downtime for peak efficiency.

With rack heights over 10 meters and double-deep storage, RoboShuttle offers up to 5× the capacity of traditional systems—ideal for scaling operations, increasing density, and boosting throughput without expanding your footprint.

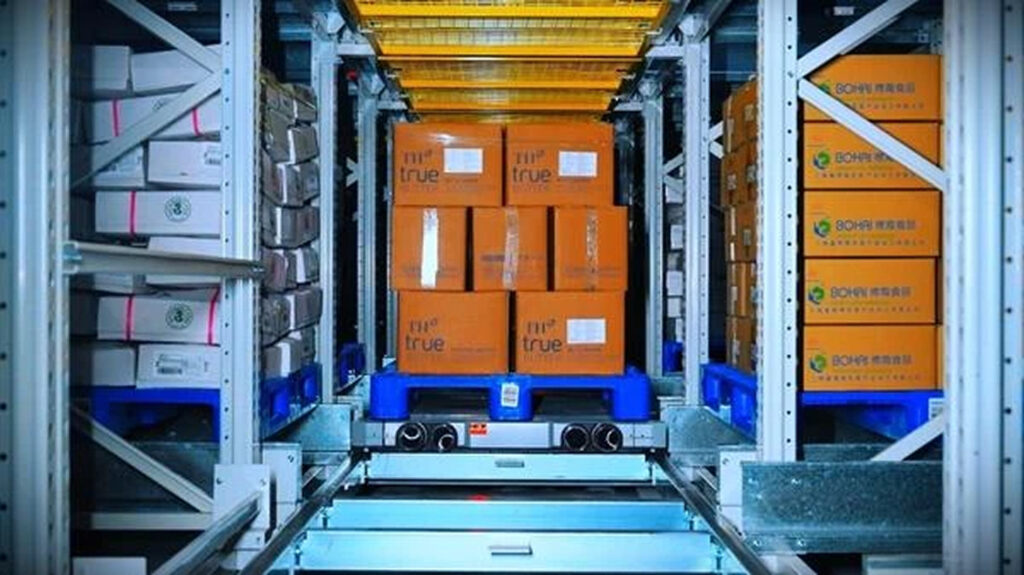

Pallet-to-Person

SkyCube

Geek+’s SkyCube merges a multilevel AS/RS storage solution with P- and X-Series picking robots, bringing full pallets, containers, and picks to ground-level stations. It achieves ultra-high density—up to 5–8x greater than traditional methods—and increases pick throughput by ~3x, while offering phased and scalable deployment to match growth.

Designed for B2B/B2C operations, it integrates seamlessly with conveyors, robotic arms, and wraps—demonstrated at scale with 81 % labor reduction and ~550 picks/hour for a major 3PL.

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

What is a shelf-to-person picking system, and how does it work?

Shelf-to-person systems use autonomous mobile robots (AMRs) to bring entire shelving units or mobile racks directly to a central picking station. This eliminates the need for workers to walk aisles, increasing efficiency, reducing physical strain, and improving pick accuracy.

What are the main benefits of using a shelf-to-person system like Geek+?

Geek+ shelf-to-person systems offer faster picking, greater accuracy, and up to 60% labor reduction. They also increase storage density by up to 70% and reduce travel time by bringing inventory directly to operators—perfect for high-SKU, high-volume environments.

Can this system adjust to changes in inventory or operational demand?

Yes. With dynamic inventory adjustment, heat mapping, and placement recommendations, the system continuously adapts to changing inventory patterns, seasonal spikes, and operational shifts to maximize space and efficiency.

How does the system ensure inventory accuracy and order tracking?

Integrated with RFID technology, real-time inventory management, and intelligent tally systems, shelf-to-person systems track every item from storage to pick station. This reduces stockouts, prevents overstocking, and improves decision-making accuracy.

Absolutely. From robot-to-workstation task integration to layout configurations, the system is highly customizable to fit your warehouse’s specific needs—whether you require double-deep storage, narrow aisles, or unique workflows.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields