Eliminate the Hassle of Plastic Jackets

Duplex Packslip™ eliminates the inefficiencies of traditional paper-in-pouch methods (which require 30+ seconds of labor per application) through packslip automation. By printing on both sides of a label and applying it automatically to shipments, it streamlines your fulfillment process. Simply peel the top label to reveal the hidden packslip underneath.

StreamTech manufactures systems that allow customers to realize the full potential of this technology. Implementations can include:

- The application of packslip to the back of the ship label

- Return packing slip label applications

- Batch pick and auto-assignment of orders to full-case items

- Integration of returns collateral (such as packing instructions and marketing material

See the Duplex Packslip™ in Action:

Ideal Applications for The Duplex Packslip

Duplex Packslip™ is the ideal solution for shipping items in their original packaging while still including a packing slip or return label for your customer. Upgrading your fulfillment process to include packslip automation can save you both time and money.

StreamTech WCS can allow for FIFO fulfillment using reverse look-up of oldest order – a home run!

- “Ship Alones”

- Items needing no repackaging

- Return Kits

- Replaces printed paper in plastic jacket applications

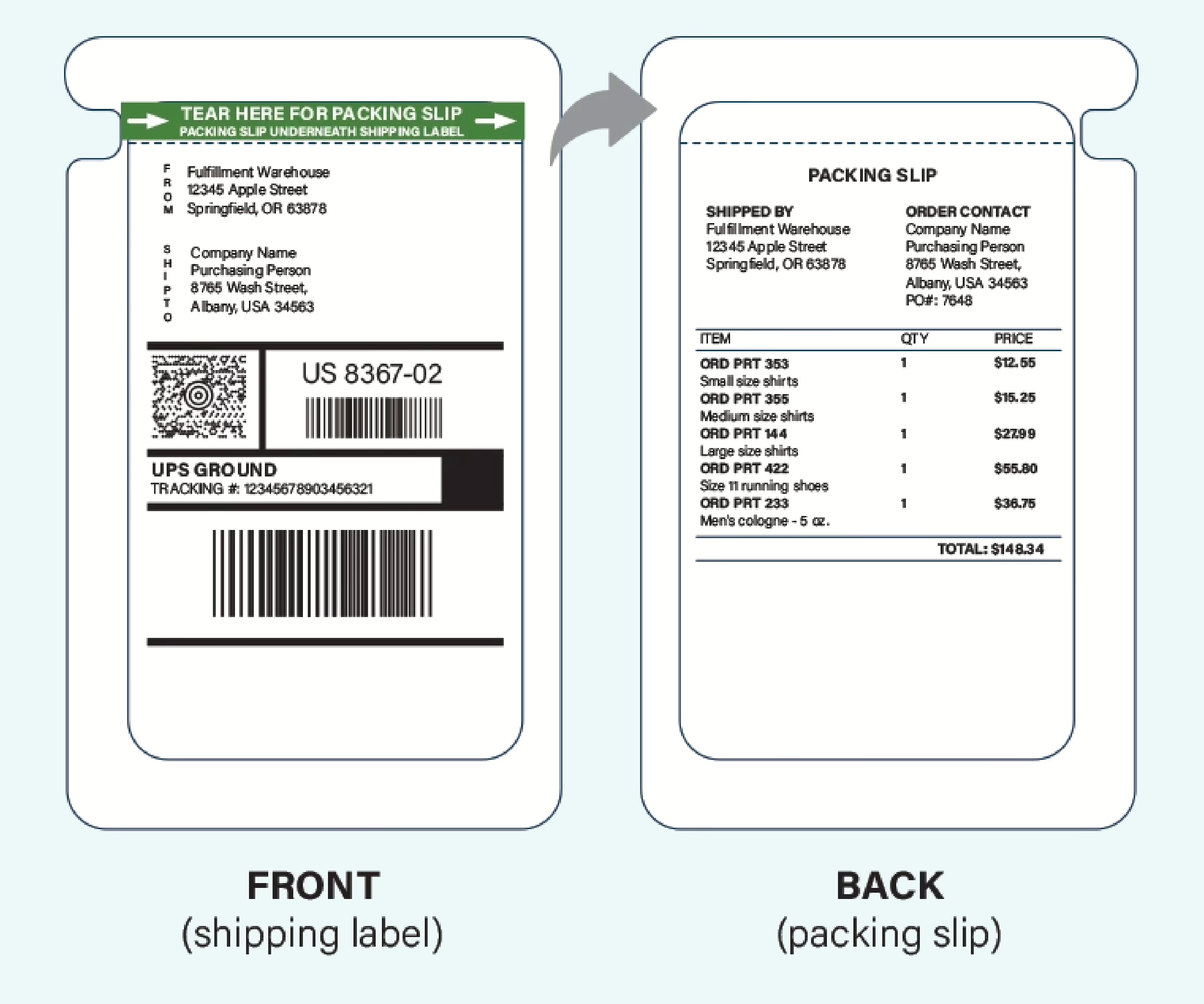

Pack Slip on Back

The top label can be removed, revealing a packslip on the back side.

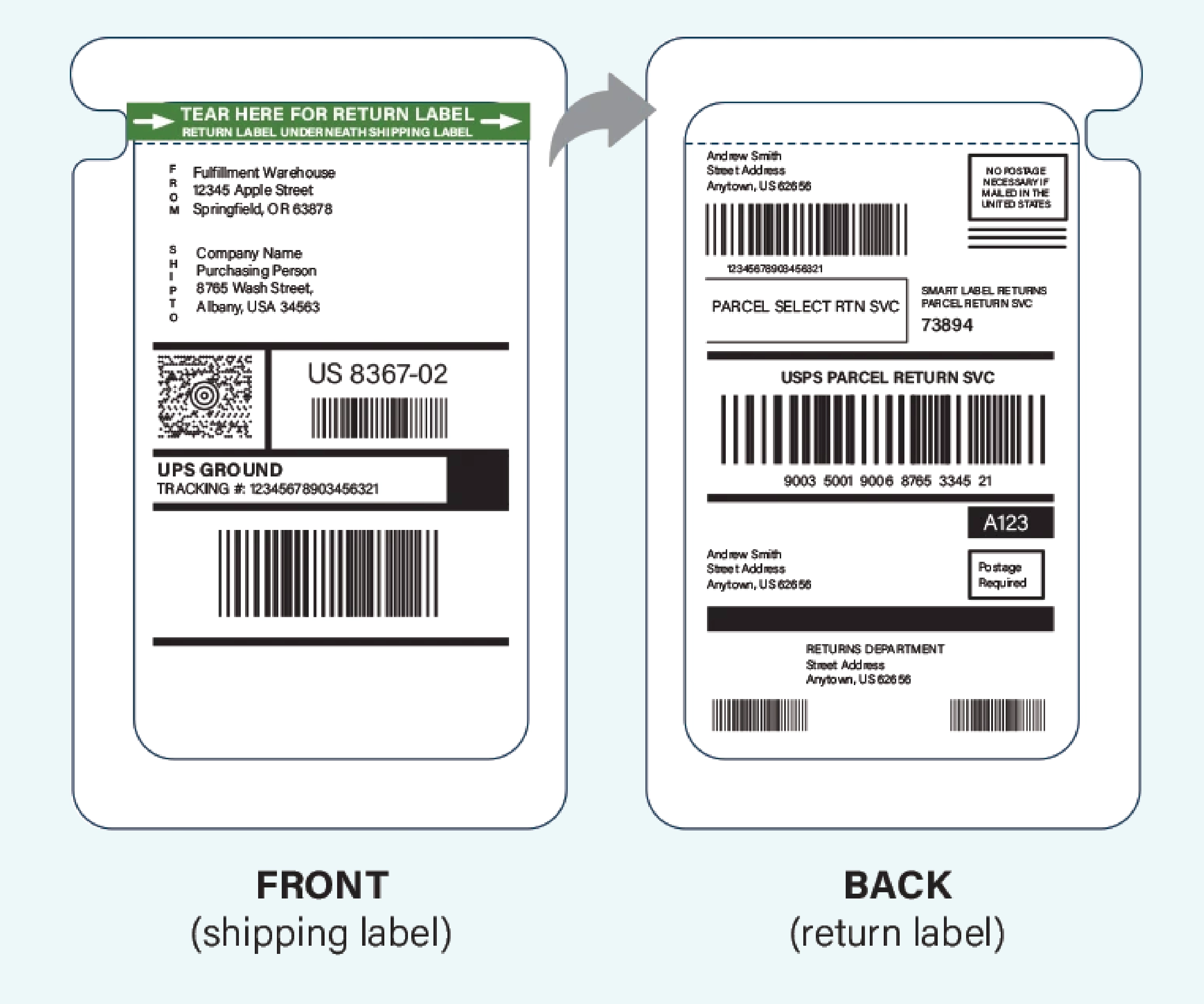

Return Label on Back

The top label can be removed, revealing a return label on the back side.

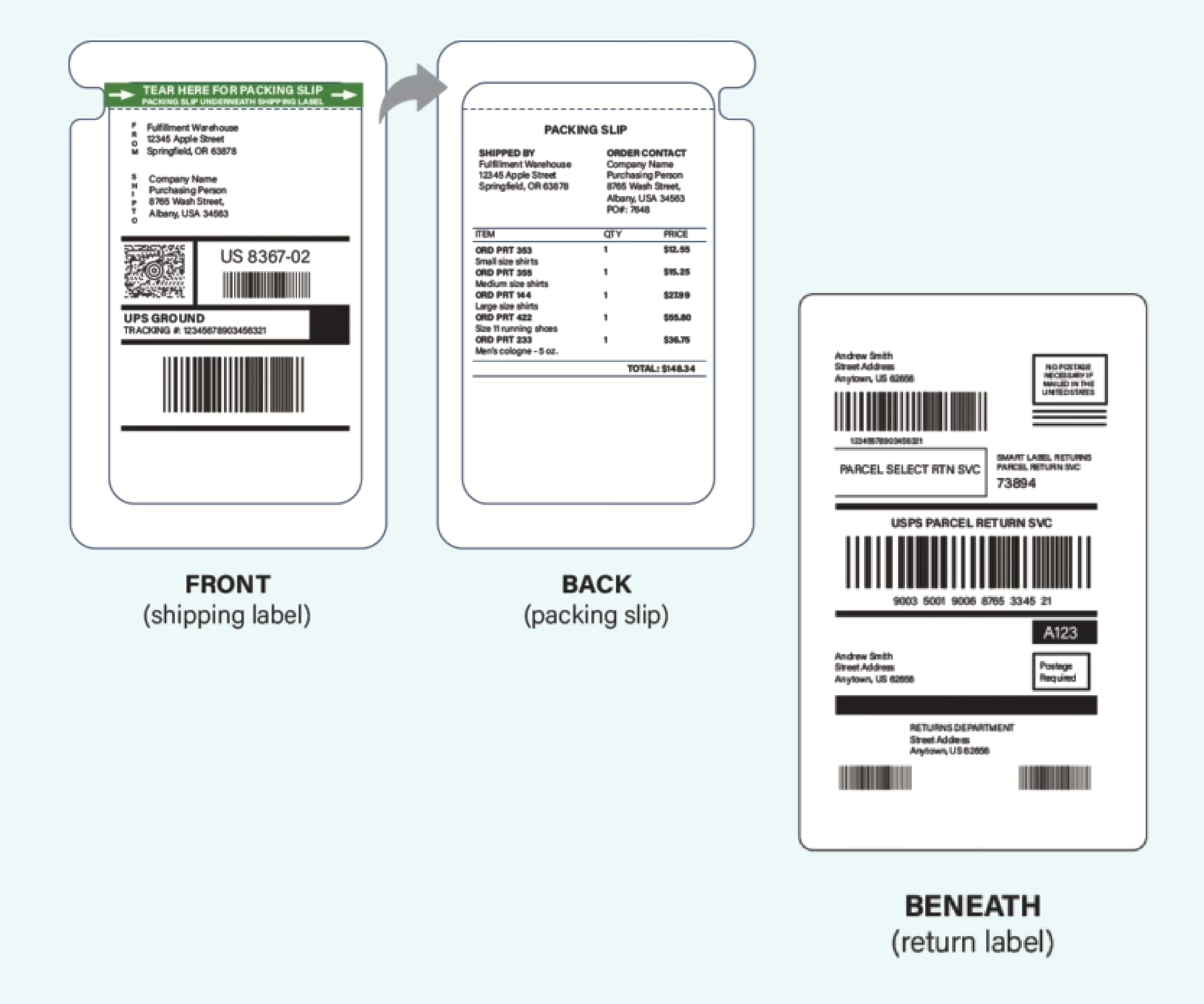

Pack Slip on Back, Return Label Beneath

Or, the Duplex Packslip label can be placed atop a return label that is adhered to the box.

Your Smart Warehouse Starts Here

The Duplex Packslip isn’t just a label solution — it’s a smarter way to complete your outbound process. Integrated with StreamTech’s full automation suite, it streamlines documentation while keeping your operation moving at top speed.

What our customers say

Frequently Asked Questions

If you have any further questions, please don’t hesitate to contact our customer support team for assistance.

With the Duplex Packslip, you reduce material costs, eliminate the hassle of plastic jackets, and save time in your packing process. It also provides a cleaner, more professional presentation for your customers while ensuring all shipment details are secure and protected.

Yes. Our team designs the Duplex Packslip solution to work seamlessly with your current workflow, whether you’re running semi-automated or fully automated packing lines. It can integrate with your existing Warehouse Management System (WMS) and other StreamTech automation technologies.

We can configure the Duplex Packslip to fit your label requirements. Our systems support common label sizes used across the industry, and we can adapt the solution to meet your specific operational needs.

We stand behind every solution we install with our Lifetime Support program, which includes remote technical assistance, preventative maintenance, spare parts programs, and ongoing software updates to keep your system running at peak efficiency.

The labels are 6 x 8 inches.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields