Automate promotional inserts with ease.

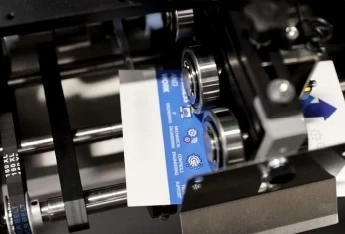

CardSerter™ is a high-speed friction feeder that inserts pre-printed postcards into outbound orders right on the pack line. Whether you’re adding promo codes, thank-you notes, or seasonal offers, CardSerter ensures every box delivers the right message—without slowing down your operation.

Features & Benefits

High-Speed Insertion

Capable of up to 3,000 cartons per hour, CardSerter keeps pace with high-volume fulfillment lines—no slowdown, even during peak.

Boost Customer Engagement

Insert marketing collateral, coupons, or thank-you cards to enhance the unboxing experience and encourage repeat purchases.

Modular & Scalable for Multi-Insert Workflows

Deploy a single unit or run multiple CardSerters in sequence to insert a variety of materials—from instructions to promotional pieces.

Reliable, Low-Maintenance Performance

Engineered for uptime and ease. The industrial-grade friction feeder requires minimal maintenance to run smoothly.

Flexible Insert Compatibility

Handles standard postcard-sized documents, making it easy to update promotions or rotate collateral across campaigns.

Accurate, Repeatable Placement

Every insert lands where it should—precisely and consistently—delivering a polished, professional finish in every box.

CardSerter™ in Action: Fast, Flexible Collateral Insertion

See how our CardSerter™ automates the insertion of pre-printed cards, brochures, and marketing materials into open cartons—at speeds of up to 3,600 packages per hour. This friction feeder solution is a powerful way to add value, promote repeat business, and streamline outbound fulfillment with precision and ease.

Fast Throughput

Handles up to 3,000 cartons per hour per line—built for busy pack lines and peak season surges.

Easy to Use

Operators can easily pre-load large stacks of inserts and let the automation system do the rest, meaning one less manual touch needed for each order.

Configure Multiple Feeders

Many feeders can be set up in series, triggering based on rules by LPN or some other pre-set control logic. Ideal for tailoring your marketing materials to specific product lines or promotional campaigns.

Your Smart Warehouse Starts Here

The CardSerter™ is just one piece of the puzzle. Integrated with picking, packing, and shipping automation, it becomes part of a seamless, end-to-end fulfillment system built to maximize speed, accuracy, and efficiency.

Driven by Intelligent Software

Intelligent Warehouse Control System (WCS) Software

StreamTech bundles our operational and maintenance know-how in the onboard software app that comes on the included Windows Pro 64-bit SSD PC, with rich functionality that supports troubleshooting and enhances uptime. The intelligent warehouse control (WCS) software easily integrates with rules-based multi- carrier systems or direct carrier interfaces.

- Extensive troubleshooting built-in to the system

- Smart filtering of label files

- Expandable for growing customers

- Rich scan, production, and maintenance statistics with configurable retention

- Server-based thin client solutions are available

- Backup UPS included protecting PC and SQL database

- Multi-level security, multi-user login

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

What types of materials can the CardSerter™ insert?

CardSerter™ is designed to handle small postcard-sized inserts such as promotional flyers, discount coupons, thank-you notes, loyalty offers, and seasonal marketing campaign collateral—making it easy to enhance the customer unboxing experience.

How fast is the CardSerter™ system?

CardSerter™ delivers high-speed performance, inserting up to 3,000 cartons per hour per line. It’s built for high-volume operations and peak seasons, maintaining speed without compromising accuracy.

Can I use multiple CardSerter™ units in sequence?

Yes. Whether deploying as a single unit or a series, we can deploy multiple CardSerters™ to insert different materials (e.g., instructions + promotional piece) based on control logic or LPN rules. One common implementation is to have one unit insert a promotional material to cross-sell a specific product, while another one promotes a different product – configured by the LPN or UPC.

Does the CardSerter™ require specific software?

The CardSerter™ can run in two ways—integrated with our Warehouse Control System (WCS) to read and associate insert data from the LPN or order information, or configured for standalone operation using PLC programming and HMI controls. This flexibility lets you choose the right level of intelligence based on your needs and system complexity.

How reliable is the CardSerter™ in long-term use?

Engineered for durability, the industrial-grade friction feeder is low-maintenance and highly reliable—ensuring consistent insert placement and uptime across demanding, fast-paced environments. Routine care includes simple checks such as cleaning feed belts and rollers to remove dust or debris, wiping sensor lenses to maintain accurate detection, and inspecting wear parts during scheduled downtime to keep the system performing at its best.

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields