Reliable Automation for Cold Chain Fulfillment

Engineered to Meet the Demands of Temperate-Sensitive Fulfillment

Protect Food Integrity During Fulfillment

Cold chain fulfillment demands precision at every step, puts a strain on staff, and has to operate under tough requirements.

StreamTech’s automation solutions are built to improve throughput, reduce manual exposure, and protect temperature-sensitive products throughout the supply chain so your product arrives on time, and intact for the customer.

Automation for each step in the fulfillment process.

Reduced Manual Labor in Cold Storage

With robotic picking automation, conveying into and out of cold storage areas, automation can reduce the amount of manual labor required in cold zones.

Fast, Accurate Pack & Ship Process

Automated dimension, weight and shipping labeling can reduce the dwell time outside of cold storage, and ensure the product ships on time to meet carrier cut-off times, to arrive at the customer’s door before expiry.

Pack Automation for Cold Packaging

Automated case erectors can help speed up the pack process, and automation can guide operators to the correct amount of ice for each order.

Seamless System Integration

StreamTech’s WCS synchronizes cold chain workflows, from material handling to data capture, keeping operations smooth and compliant.

Quality Assurance is Built-In

Automated scan verification at each stage in the fulfillment process increases order accuracy. Additional features such as checkweigh or direct image capture can help ensure product quality.

Compliance with Industry Standards

For perishable items, StreamTech systems support documentation, traceability, and handling protocols required by strict industry standards.

See How Mason

Companies Continues to

Grow with Automation

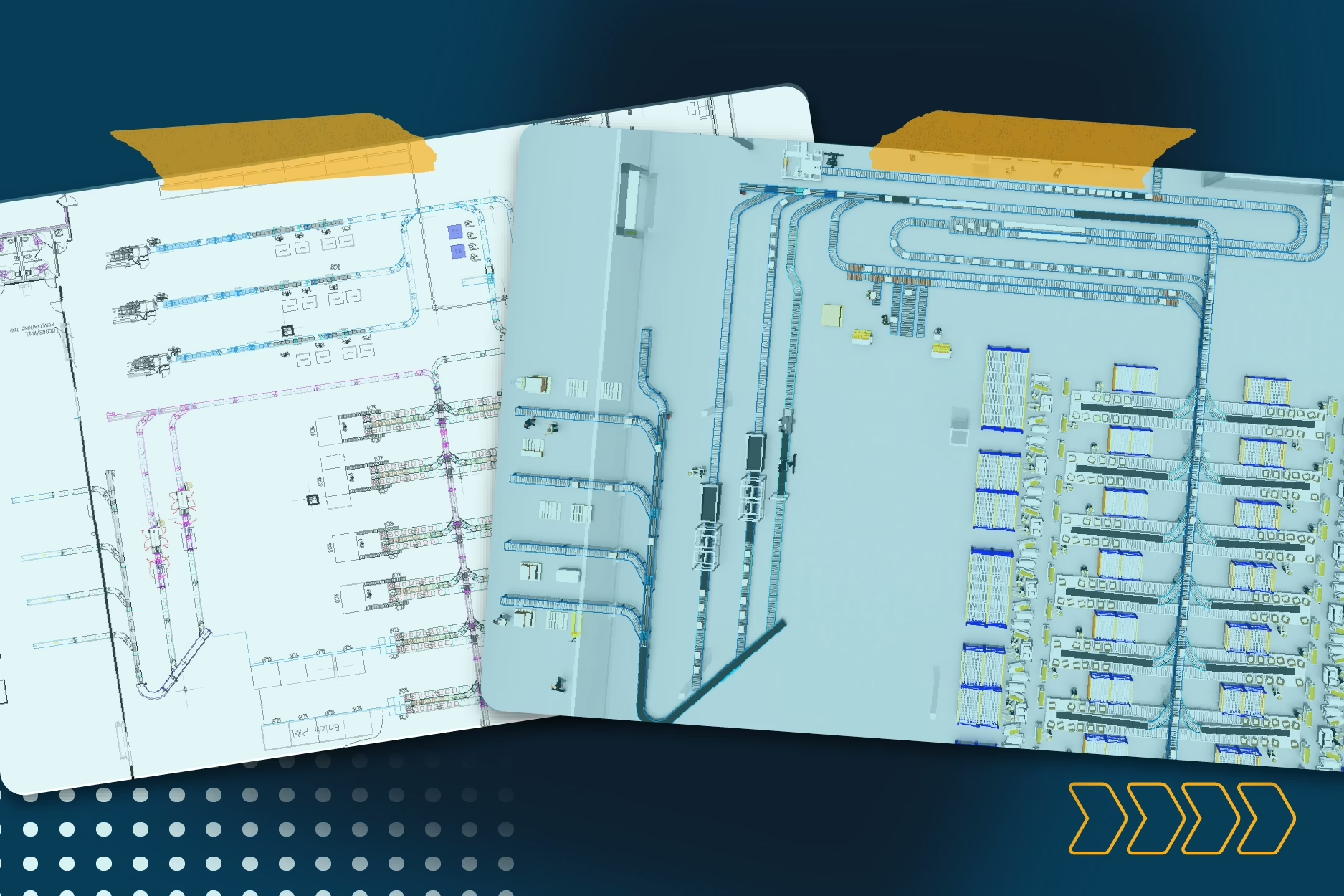

Mason’s continued growth initiatives and diverse product offerings required multiple fulfillment systems and packaging equipment. Now, Mason’s expansion has brought all their brands under one fulfillment and distribution center.

Your Smart Warehouse Starts Here

From refrigerated sorting to insulated packing, we design fully automated warehouse solutions built for the unique demands of cold chain fulfillment. Streamline temperature-sensitive operations, reduce handling time, and maintain product integrity every step of the way.

The Pack Process is Critical to Cold Chain Success

Get the packaging right, every time – including the right amount of ice.

Many solutions are available to both assemble the box, as well as verify the proper packaging – checkweigh or dimension, to ensure consistency and accuracy every time.

Maintain Compliance in Shipping

Protect product quality and meet regulations.

StreamTech automation helps you minimize exposure times, ensure accurate labeling, and meet strict handling requirements, reducing risk and improving compliance.

Increase Pick Speed and Accuracy

Take the guesswork out of order assembly.

Pickers can simply follow a guided pick process to ensure every item is in the order.

Scale to Meet Growing Cold Chain Demand

Expand confidently without sacrificing integrity.

With global demand for cold chain fulfillment rising, StreamTech solutions help you increase capacity and performance while maintaining critical temperature controls.

Improve Throughput in Harsh Environments

Speed up fulfillment, even in the cold.

Our temperature-resilient systems and conveyors increase speed and accuracy in chilled and frozen zones, reducing labor strain and bottlenecks.

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

How does StreamTech help maintain product integrity in cold chain environments?

Our systems are designed to reduce dwell time in temperature-sensitive zones, helping you move perishable goods quickly and efficiently through each fulfillment stage. From cold storage to pack-out, we prioritize maintaining the cold chain and minimizing manual handling to preserve product integrity.

Can your automation solutions operate in refrigerated or frozen environments?

Yes. We engineer and select automation components that are built to withstand cold, humid, and even sub-zero conditions. From conveyor systems to scanning and sorting equipment, we account for temperature, condensation, and durability in every design.

How do you ensure compliance with food safety and pharmaceutical regulations?

Our systems help you meet strict regulatory standards by supporting traceability, consistent labeling, accurate weight verification, and reduced human touchpoints. We can also integrate temperature monitoring, audit logging, and compliance documentation into your workflow as needed.

Can your system handle both frozen and refrigerated SKUs in the same facility?

Yes. We build flexible workflows that can handle a range of product zones, including ambient, chilled, and frozen. Our automation allows you to batch and route orders based on storage type, with intelligent sortation and staging that supports efficient multi-zone fulfillment.

Do you offer ongoing maintenance and service for cold chain systems?

Yes. We provide proactive support, including remote diagnostics, preventative maintenance plans, and easy access to spare parts. Cold chain environments are tough on equipment, so we stay hands-on to ensure long-term performance. Learn more about our support services.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields