How D2C Brand Turns Fulfillment Challenges Into Streamlined Operations With Faster Picks, Smarter Shipping, And Lower Costs.

1st Phorm

This premium fitness and wellness brand turned to automation to keep pace with rapid growth and rising D2C fulfillment challenges. The new end-to-end fulfillment automation system reduced picker training time from weeks to days, eliminated costly carrier back charges, and created a scalable foundation for future expansion.

Overview:

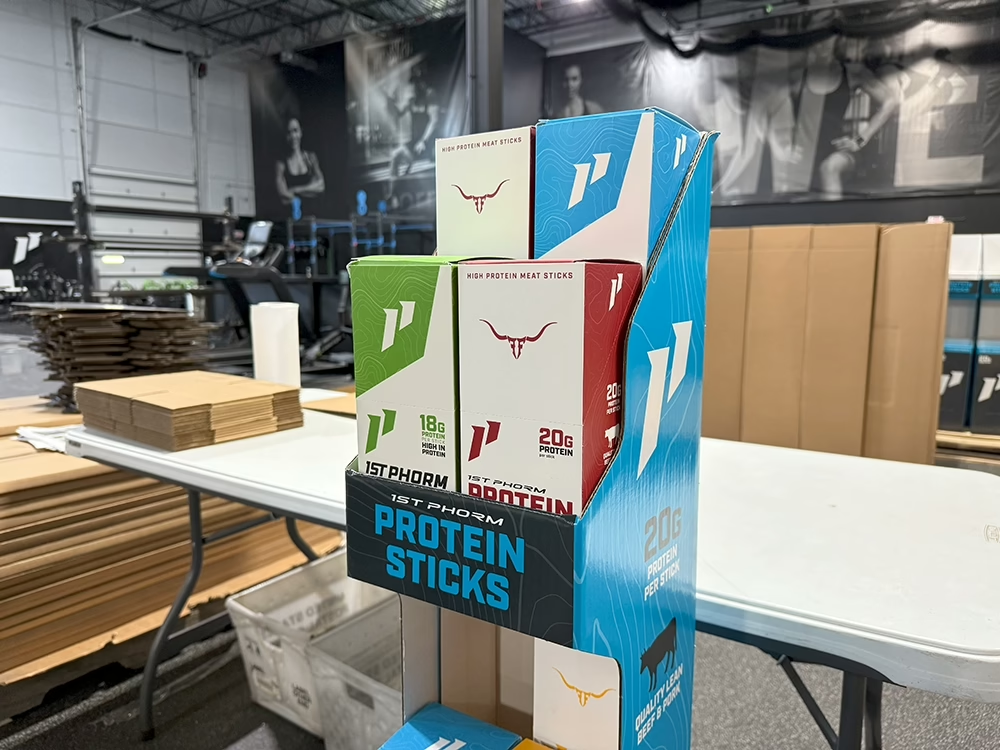

1st Phorm is a fast-growing, premium fitness and wellness brand headquartered in Fenton, Missouri, that specializes in high‑quality nutritional supplements and athletic apparel. Founded in 2009 by brothers Andy and Sal Frisella, the company embeds Midwestern grit and values—leadership, loyalty, humility, discipline, initiative, enthusiasm, selflessness, and relationship‑building—into everything it does, from formulation to customer experience.

More than just a supplement provider, the brand has cultivated a culture of empowerment and transformation, engaging customers through fitness challenges, fostering strong connections with micro-influencers, and inspiring loyal users to become passionate advocates through a shared sense of community and achievement.

Rapid Growth Challenges:

Due to 1st Phorm’s rapid growth in both customers as well as products, their fulfillment center had to jump through many of the growth phases quicker than most companies do, in order to support the business appropriately. Their warehouse had several D2C fulfillment challenges:

- Carrier Back Charges: Without shipping by dimensional weight, 1st Phorm had incurred substantial back-charge fees from carriers. An eye-opening cost that demanded immediate attention. This is one of the most traditional, common fulfillment challenges that D2C (direct-to-consumer) e-commerce companies face. Without automating dimensional weight, it’s very easy to underestimate the carrier cost per package – and carriers will still deliver the order, but they’ll charge you back for the difference later (sometimes with fees included).

- SKU Proliferation for Picking: New product launches and frequent SKU changes created inefficiencies in picking. Training new employees took weeks, and even experienced pickers struggled to keep up with constant item relocations. When a SKU moves around, or a new SKU takes it’s place, the picking staff had to remember where that SKU went. Picking can be a common strain for growing e-commerce companies.

The Automation Solution

So, in comes the automation. StreamTech worked with 1st Phorm and their packaging team to transform their fulfillment operations end-to-end:

- Robotic Carton Erector: Orders are inducted and cartonized by the software, to allow the robot to select the right size box sleeve that matches for the order size. Once the box is made, it’s given a unique LPN (associated to the order ID) and inducted into the system to begin the pick process.

- Zone Picking with Pick-to-Light: A conveyor-based zone picking system directs orders throughout the system, and guides operators using pick-to-light devices. This provides a much more consistent workflow for the operators. Pickers simply scan the box, and look for the appropriate lighted device. This drastically reduced the training time to just a few days, while accelerating throughput for picking.

- Quality Assurance Check: Once orders have made their way through the pick process, they’re sent down to the QA station. Here, we checkweigh each order against the expected weights, and divert any orders that are outside of spec. A manager then checks these orders later to address any issues.

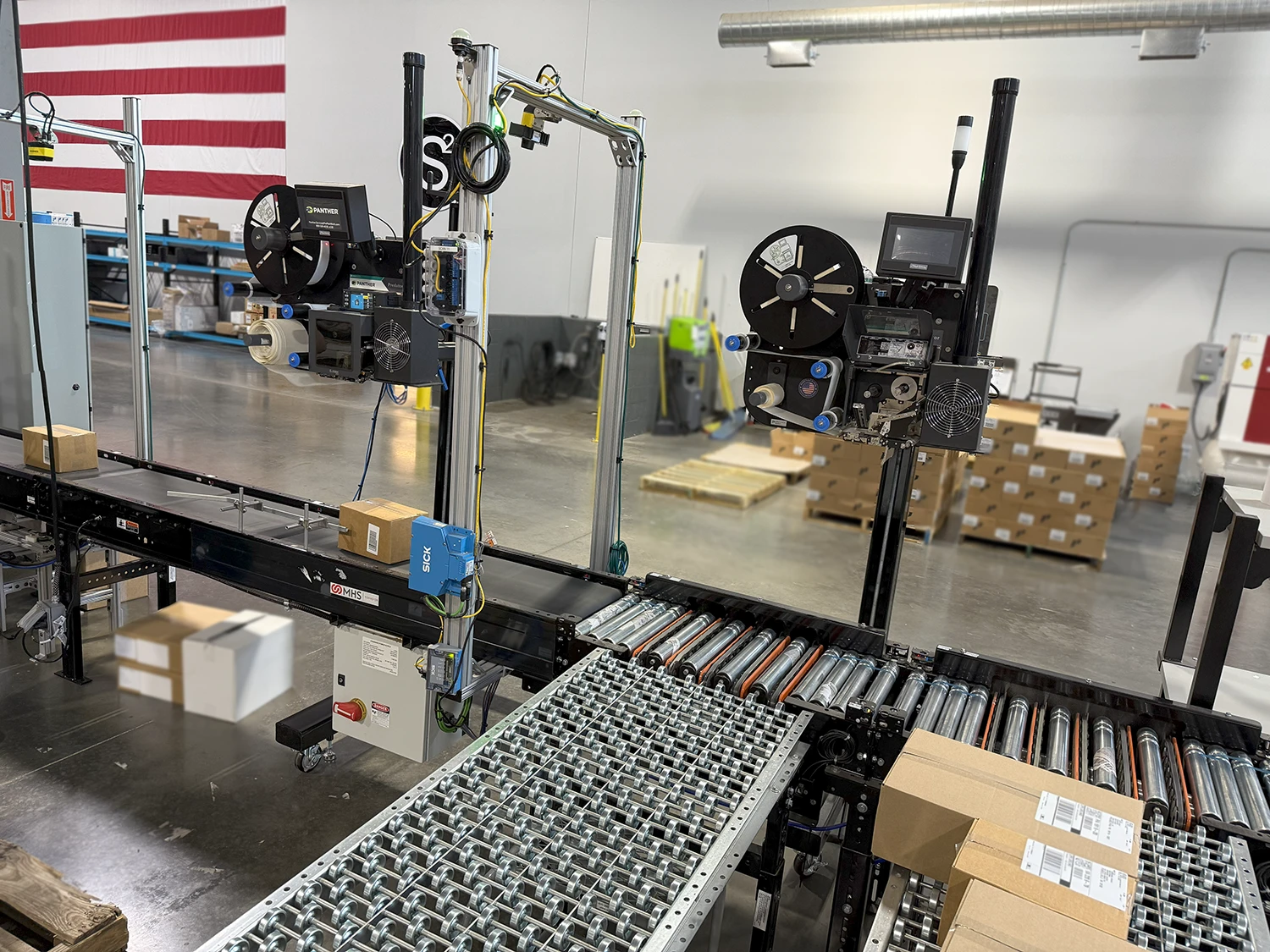

- End of Line Shipping System: Orders get void fill, semi-automated tape sealing, and move through the dimension, weigh, print-and-apply labeling and parcel sortation area. Most importantly, by capturing accurate weights and dimensions, the software can rate shop by carrier to ensure the most efficient carrier was chosen, and eliminate costly carrier back charge fees.

Results & Impact:

For many businesses, implementing automation of this scale would be a daunting first step. But 1st Phorm’s culture embraces big projects and calculated risks. Their decision to move forward paid off: fulfillment operations are now faster, more accurate, and more cost-effective—giving the brand a scalable foundation for continued growth.

StreamTech is proud to have partnered with 1st Phorm on this journey and continues to support their evolving needs.

Ready to tackle your own fulfillment challenges? Let StreamTech help you design an automation solution that drives efficiency, accuracy, and growth.