Estimated reading time: 6 minutes

When orders start to pile up, many fulfillment operations add more people. Many times, this isn’t just an issue of dealing with higher volume, but of “just-in-case” staffing: Hiring on extra workers because processes and equipment aren’t reliable enough to operate independently of human supervision.

True, your workers can be an insurance policy against scanners misfiring, sorters jamming, or packages being rejected. But what looks like a smart safeguard on paper often hides deeper problems. Too many warehouses are employing too many workers (“overstaffing”) simply to mitigate the risks that come from complex systems which might fail when they are needed most.

This type of solution – adding people to cover for what the equipment should have been handling – destroys the ROI of the initial project investment. So how can a forward-thinking warehouse operation start doing that?

The Results of Poorly Implemented Automation

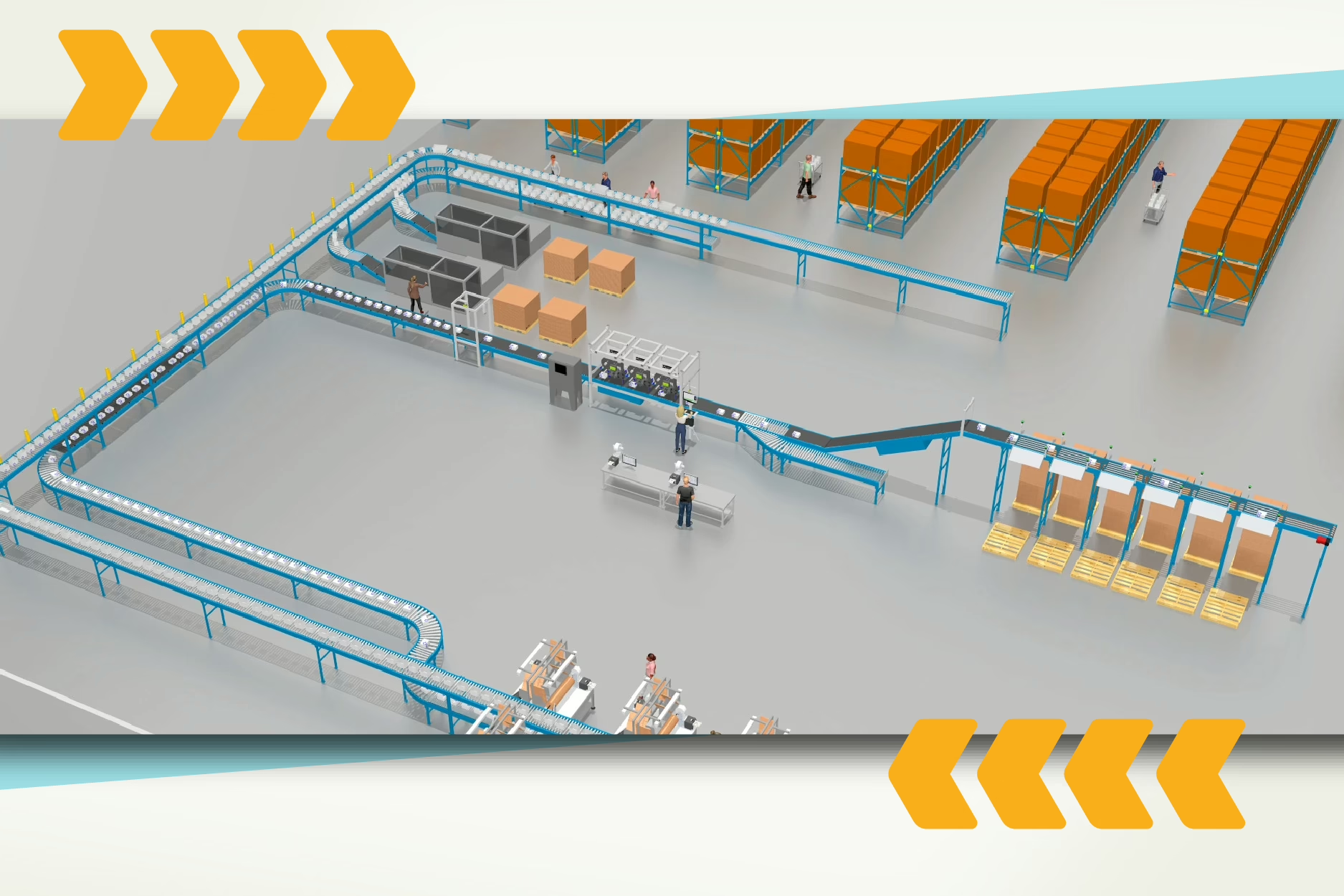

When automation is implemented, it’s important to pay attention to the details – how packages will align, travel along the conveyor around tight curves, remain singulated from other packages, between pack stations. Sometimes we walk into a warehouse that looks highly automated with a lot of equipment. However, upon closer examination of how efficiently the systems are working, or how people are utilized, a pattern emerges: we see additional personnel there to compensate for fragile systems.

For example:

- A pack station operator is pulled to the side to manually relabel packages kicked out of an automated line.

- Workers are stationed near a jam-prone sorter “just-in-case” something goes wrong.

- Teams lose minutes on every order when scanners misread barcodes, requiring multiple rescans.

- Pickers fall back on paper lists because the warehouse management system (WMS) isn’t syncing in real time.

- Quality assurance staff are added because it seems like the only way to boost pick accuracy.

- Pickers are sent to retrieve single items on individual trips, which is hugely inefficient.

None of these situations are unusual. In fact, they’re common across fulfillment centers of all sizes. They reflect managers doing their best to keep orders flowing. But they also highlight that labor is being used as a bandage for automation detail breakdowns.

Other red flags of system fragility can be harder to spot but just as costly: unexpected spikes in overtime even when order volume is steady, constant “workarounds” that only veteran employees know how to execute, bottlenecks that appear anytime a single workstation goes down, or a reliance on shadow spreadsheets outside of the WMS.

These are signs that your operation is vulnerable, and that labor is covering gaps in process reliability rather than fueling growth. That’s the hidden cost of “just-in-case” staffing. It keeps production moving, but it prevents real fixes from taking hold. And the longer the cycle continues, the more expensive and disruptive it becomes.

Why Just-in-Case Staffing Isn’t a Real Solution

Adding more people to the floor may work temporarily, but it doesn’t address the underlying fragility. In fact, it’s the main problem the automation is meant to solve. Even the most dedicated team will grow frustrated if they’re asked to catch mistakes instead of solving the root causes.

It’s important to note that strategic labor increases are different. Adding staff to handle seasonal peaks or rapid business growth is a smart warehouse labor strategy. What’s unsustainable is building your baseline operation on fragile systems that demand constant human backup. The real risk is dependency: Once you normalize just-in-case staffing, your business can’t function without it. That makes every new hire a short-term fix that reinforces a long-term problem.

When you peel back the layers, most fragile systems share a common thread of too many manual interventions. Individually, the workarounds we use to solve these problems may seem minor. Collectively, they create a warehouse that relies on human vigilance rather than system reliability. Many processes can’t stand on their own, managers are forced to hire “just-in-case.” The good news? Fragility isn’t inevitable. With the right tools, chaotic workflows can be transformed into predictable, resilient systems. That’s where targeted automation and system integration come in.

A Better Approach: Automation and System Integration

The alternative to just-in-case staffing is removing the fragility that makes those extra positions necessary. Targeted automation and tighter system integration turn reactive labor into proactive efficiency.

Think about the earlier examples:

- Reliable scanning reduces the need for repeat barcode reads, allowing operators to focus on throughput instead of troubleshooting.

- Automated exception handling manages packages with missing or damaged labels without pulling workers off the line.

- Well-tuned conveyors and sorters minimize jams, eliminating the need for a permanent “babysitter” nearby.

- A Warehouse Control System (WCS) keeps automation, WMS, and pack station in sync, preventing the fallback to paper lists.

- Pick-to-light systems guide pickers efficiently, cutting down wasted trips for single-item pulls.

- Integrated WMS and scanning lessen reliance on extra QA staff by ensuring accuracy is built into the process from the start.

Together, these improvements address the fragile points that quietly drain labor hours. More importantly, they enable employees to focus on higher-value work that directly enhances flow and customer satisfaction, including accurate picking, safe packing, quality checks, and handling true exceptions that require human judgement. A well-tuned warehouse control system not only keeps automation and WMS in sync but also provides real-time visibility, so managers can anticipate issues instead of reacting to them.

Industry research underscores the opportunity. Estimates show that transport and warehousing have some of the highest automation potentials of any sector, fueled by labor shortages, rising e-commerce demand, and rapid advances in technology. The payoff extends well beyond labor savings: Reliable systems reduce errors and rework, improve throughput, and create a better environment where people contribute strategically instead of reactively. In short, warehouse automation ROI is measured not just in labor efficiency, but in resilience. Instead of structuring your warehouse labor strategy around constant backup staff, you trust your systems to perform and your people to deliver their most significant impact.

Creating Warehouse Automation ROI

Overstaffing to cover fragile systems is understandable—every manager wants to keep operations running smoothly. But it’s not sustainable. When employees spend their shifts guarding sorters, re-scanning barcodes, or fixing mislabeled cartons, their effort is wasted on treating symptoms rather than the underlying issues. The real measure of warehouse automation ROI is the ability to scale confidently without over-relying on just-in-case staffing.

By addressing fragility with automation and integration, you free people to do their core tasks: accurate picking, safe packing, and ensuring products flow smoothly to customers. That shift builds resilience. And resilience is what turns just-in-case staffing into confident, scalable operations. If your team struggles to cover fragile processes, let’s discuss how StreamTech can design systems that run reliably, freeing your people to focus on what matters.