Estimated reading time: 11 minutes

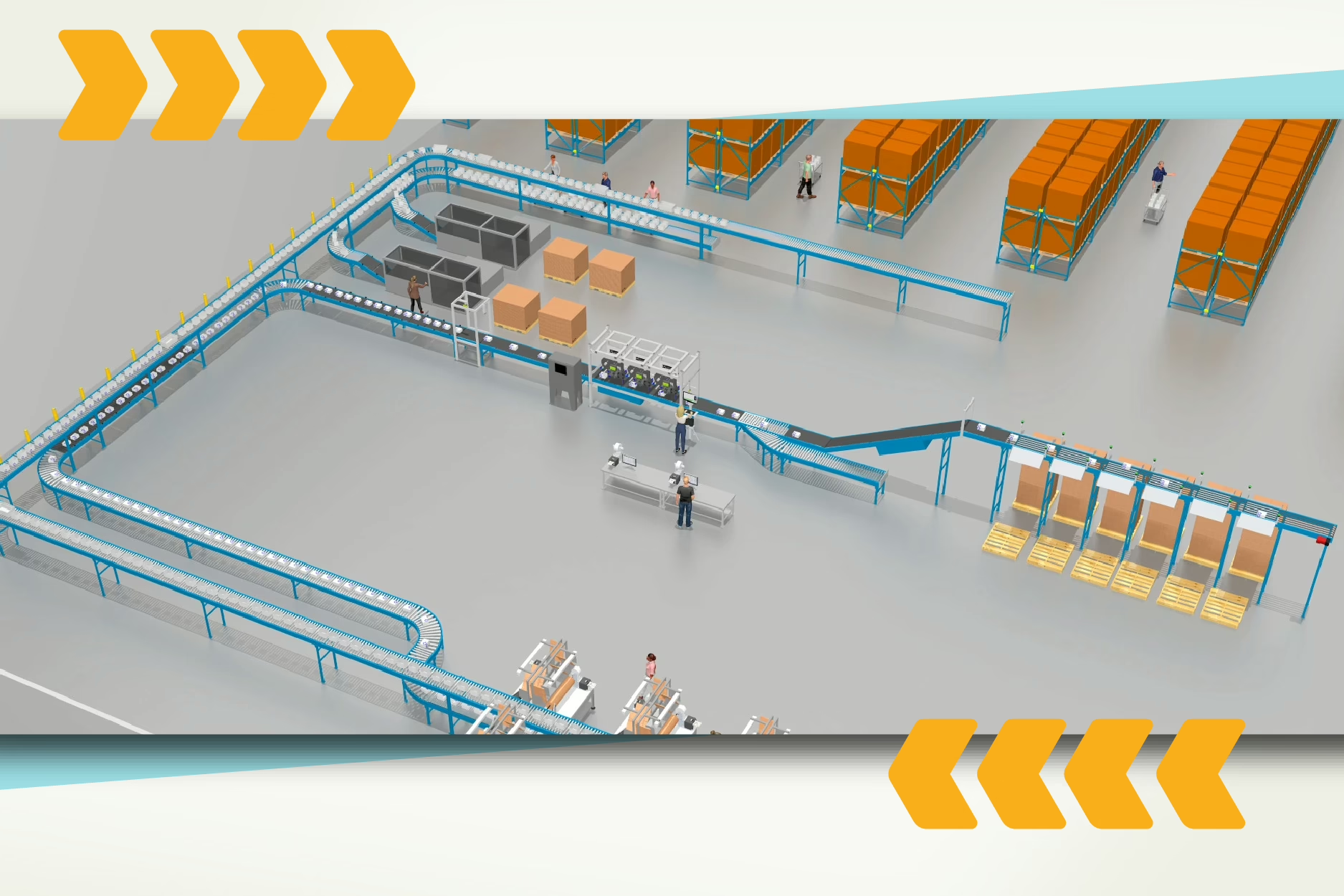

The term goods-to-person automation has become a point of focus in discussions about modern warehouse automation. The idea is simple: Instead of employees walking miles (literally) each day to find and pick items, the system brings products directly to the worker, thereby cutting wasted motion, reducing errors, and increasing throughput. But despite the buzz, there are still misconceptions about this technology and what it really takes to implement it successfully on the ground in a warehouse.

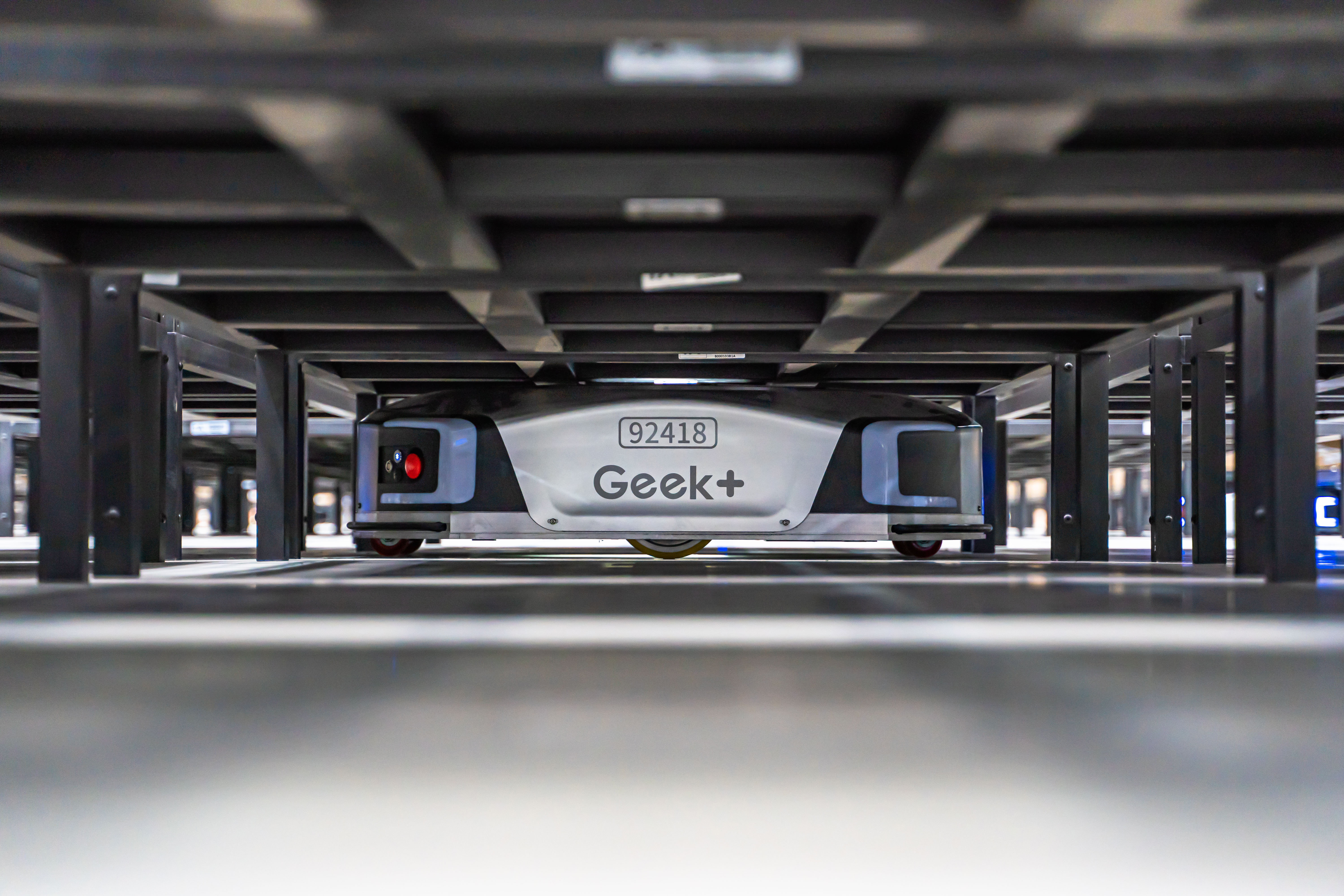

That’s where Geek+ and StreamTech come in. Geek+ has become a global leader in robotics-powered warehouse automation, while StreamTech focuses on designing and integrating fulfillment solutions that fit warehouses’ unique needs. Together, they’re helping warehouses rethink how work gets done. To dig deeper, we sat down with Corey Bellovich, Regional Sales Manager of Geek+, to talk about what goods-to-person really means in practice, why it matters now, and what companies should know before getting started.

StreamTech:

Most readers have probably heard of robotic goods-to-person automation, but they might not be too sure about what that means in practice. So, tell us in your own words: What exactly is goods-to-person automation? How would you describe it in a common warehouse application?

Geek+ (Bellovich):

“Goods-to-person” means that warehouse personnel no longer need to walk from location to location in a large warehouse to fulfill orders as they would in traditional order fulfillment. We use AMR technology to bring SKU locations to a stationary worker. This results in increases in pick efficiency and accuracy, and because we can control how items are stored and presented, it also improves ergonomic working conditions.

For example, we use storage logic in the software layer to place the most frequently picked items in the “golden zone” around waist height, and heavier items are stored lower by default. This reduces strain and makes the picking process more comfortable for associates.

StreamTech:

How flexible are these systems in supporting different workflows? For example, are they limited to totes and cartons? Or pallets?

Geek+:

We see all of the above. Many customers pick-to-totes and then sort downstream. Others pick directly to shipping cartons, and in those cases we can even trigger a label print automatically after the last pick. We also support full-case and pallet picking, which is common in certain industries. Ultimately, the workcell layout determines the workflow. The system is flexible enough to support totes, cartons, or pallets depending on the operation.

StreamTech:

So how does this differ from traditional picking? And what about other kinds of automation systems from picking? Does it compete with those, or complement?

Geek+:

Having SKU locations brought to a stationary associate improves pick efficiency by as much as 2-3X because associates no longer have travel time between SKU locations impacting productivity. Consider how things are done traditionally: On a given day the average warehouse associate prints a pick ticket. they would then have to plan their routes around a cavernous warehouse to ensure their movements are as efficient as possible. Oftentimes those movements are tailored by pick sequence as well as minimal travel.

2-3X

Picking Efficiency

With AMR-driven goods-to-person, the system determines optimal storage placement, sequencing, and batch picking strategy, so the associate simply picks what’s presented.

Goods-to-person also requires limited fixed infrastructure, allowing flexibility in warehouse layout. This differs from expensive fixed infrastructure technology that tends to be immovable once deployed and influences warehouse layouts for years. With AMRs, the only fixed infrastructure are the workcells and AMR chargers.

But, underneath it all, the real differentiator is the software. Our system can handle complex storage logic (lot-tracking, expiry, FIFO, and replenishment prioritization), which is particularly important in sectors like grocery and pharmaceuticals. In many implementations, the goods-to-person software layer effectively takes over slotting decisions that would otherwise be handled manually or by the WMS.

StreamTech:

Can you say more about slotting? There seems to be a lot of buzz around that topic; how does a system like yours help with that?

Geek+:

So, slotting is one of the core strengths of the AMR system. We look at the previous 30 days of order data and automatically re-slot SKUs to keep fast movers near the workstations. Because all material is stored in mobile racks, re-slotting doesn’t require labor. The system can reorganize itself during off-hours.

This also supports multiple picks per presentation. When a rack arrives at the workstation, the system tries to ensure the picker can fulfill several order lines from that same presentation instead of just one. that dramatically increases throughput.

StreamTech:

When you start saying words like “throughput,” we naturally start thinking of things like ROI. So, from a business perspective, what are the main ROI drivers for goods-to-person? (Is it labor savings, speed, accuracy, or something else?) Which industries/business models tend to benefit the most?

Geek+:

The primary ROI driver comes from increased operational efficiency. A typical client that deploys a goods-to-person system can reallocate up to 60% of their workforce toward higher-value, strategic roles such as quality control, process optimization, and customer experience. This productivity gain typically results in a full return on investment within 2-3 years.

60%

Reallocation of Workforce

Another driver is flexibility in terms of hardware and software configurability. This makes goods-to-person very popular in e-commerce, apparel, 3PL, grocery, and pharmaceutical environments where storage logic and SKU velocity vary over time.

StreamTech:

Can we talk about re-allocating workforce? Because I think that a lot of people hear “automation,” and worry that it is machines being used to replace workers. How do you see people and machines working together?

Geek+:

Well, in many operations—especially retail and ecommerce—order volume is highly seasonal. Traditionally, companies need to hire and train a large temporary workforce each year. With goods-to-person, robots can sit idle in the off-season and be brought online when volume spikes.

Many customers add additional robots to the fleet during peak, then simply turn them off afterward. This lets companies scale intelligently without the hiring, training, and turnover challenges that come with seasonal labor.

StreamTech:

So how are you seeing this technology applied out in the field? For example, do you see companies using goods-to-person picking to scale up during peak seasons? Increase storage density? Improve accuracy? Tell us about some of the more successful use cases you have seen?

Geek+:

All of the above! We’ve seen it used for scaling during peak seasons, reducing picking travel time, increasing storage density, and improving accuracy. It also helps companies avoid the cost of expanding or relocating to larger facilities by increasing how efficiently their current footprint is used.

StreamTech:

So what’s one of the more unusual implementations you’ve seen?

Geek+:

One of the more “out there” projects I’ve seen was actually a manufacturing operation rather than order fulfillment. We deployed a system to move grow racks of mycelium mushrooms used to produce a more eco-friendly and sustainable leather alternative. This required temperature and humidity-controlled storage, plus scheduled movement cycles, and the goods-to-person system handled the material flow. Part of the project involved making sure that the AMR’s could handle the environmental challenges and operate in the temperature controlled environment. And there was unique storage and retrieval logic as well. It was a very different use case, but still came down to the same core principle: Efficiently moving material from point A to point B.

StreamTech:

It’s really neat how flexible this system can be. So that’s a good segue to our next question: Many warehouse operations leaders may assume that goods-to-person is only for “mega-warehouses” or large distribution centers. Is there a play here for more mid-sized operations?

Geek+:

Yes; in fact, the scalability of a typical goods-to-person system is one of its strengths. The only fixed infrastructure are the workcells and AMR chargers. The bots themselves work off QR codes that are epoxied to the floor. We could even start clients with smaller systems—something like one workstation and ~10 robots—and expand as demand increases. Expansion can typically be completed in less than 30 days.

See our Goods-to-Person Picking page:

StreamTech:

Let’s give our readers some idea of how these systems can be implemented, and what to expect. To start off, what challenges do companies usually underestimate when adopting goods-to-person, and how can they prepare?

Geek+:

There are a few. First, there needs to be a good understanding of throughput and SLAs. Customers should have a clear handle on order volume, peak patterns, and fulfillment requirements so the system can be sized correctly.

Next would be taking a look at what happens both before and after the pick. For example, are we integrating with conveyors? A DWS system? Specific inbound or outbound flows? Knowing this up front allows us (and StreamTech) to design a more seamless total process.

Finally, this last one isn’t a challenge so much, but it is something that clients underestimate before we deploy a system, which is how much this technology actually helps with employee retention. Aside from the obvious ergonomic improvements, a goods-to-person system allows for new hires to be trained in just 15 minutes. Our IOP reporting dashboards also allow for high-level picking metrics on all associates. Many clients use this to incentivize certain performance metrics for their associates.

15

Minute Training Time

StreamTech:

If you could give one piece of advice to a warehouse manager evaluating goods-to-person for the first time, what would it be?

Geek+:

Do not be dissuaded about AMR technology when comparing it to traditional order fulfillment technology and practices. There is a reason that retail and ecommerce giants in the industry are implementing this technology: Because it works. And because of great partners like StreamTech, Geek+ can now offer low cost entry points into this new technology. There has never been an easier time to deploy this technology on a smaller scale and expand it as your business grows. It is a great time to automate!

Bringing It All Together: Why Goods-to-Person Matters Now

Goods-to-person automation is a practical way for warehouses to reduce travel time, simplify training, improve ergonomics, and double their picking productivity without expanding their footprint. As Corey’s insights show, the real power lies in how the software organizes storage, adapts to demand, and keeps operations moving through peak seasons. Whether you’re managing fast-moving e-commerce orders, handling complex storage rules in grocery or pharma, or simply planning for future growth, goods-to-person creates a more efficient and resilient fulfillment operation.

StreamTech and Geek+ work together to help warehouses understand where goods-to-person fits, how to size a system correctly, and what it looks like in real-world operations. If you’re exploring whether this technology is right for your facility, or you want to see what a starter system could look like, our team can walk you through the options and run the analysis with you. Contact us to start the conversation.

Key Takeaways

• Goods-to-person replaces long walking routes with robots that deliver storage locations directly to workers, which increases efficiency and accuracy.

• AMR technology supports totes, cartons, cases, and pallets, making it adaptable for many workflows.

• Software is the real engine behind performance gains thanks to slotting logic, storage rules, and automated reorganization.

• Typical users see productivity improvements as high as two to three times and a return on investment within a few years.

• Companies often reallocate up to sixty percent of their workforce to higher value roles rather than replacing them.

• The system scales easily for peak seasons since robots can be added or taken offline as needed.

• Mid-sized warehouses benefit because the only fixed elements are workcells and chargers, and small starter systems can expand quickly.

• Success requires understanding throughput, upstream and downstream flows, and how the system fits into the full process.

• Training takes about fifteen minutes and the improved ergonomics help with retention.

• Goods-to-person helps warehouses increase output, support growth, and use space more effectively without major structural changes.