Estimated reading time: 10 minutes

For e-commerce companies, timing is everything and customer satisfaction is king, which makes fulfillment and logistics one of the most critical drivers for success. Getting orders out the door quickly and accurately – that’s the business. But for cold-chain warehouse operators (brands who ship temperature-sensitive goods like meal kits, pet food, or pharmaceuticals), the bar is even higher. Each box must arrive fresh, safe, and on schedule – not just once, but again and again.

In this article, we will explore the challenges that cold chain logistics companies have, and how automation transforms the challenge of cold-chain subscription fulfillment into a repeatable, efficient process that keeps customers loyal while protecting margins.

Related Resources

Avoiding the Weekend Trap: Timing Strategies for Cold Chain Logistics

In cold chain logistics, the biggest challenge isn’t just speed, it’s timing. Perishable subscription boxes must reach customers within a narrow delivery window and before the ice melts and the food spoils. The real crunch happens late in the week: if shipments don’t reach carrier distribution hubs before Friday’s cutoff, they risk sitting in trailers or hot warehouses all weekend. Those idle hours can destroy product integrity, trigger refund requests, and erode customer trust faster than any other fulfillment mistake.

That’s why many cold-chain operators design their logistics calendars around carrier schedules. They front-load shipping earlier in the week to ensure deliveries arrive fresh before the weekend, even if most new subscriptions technically start on Saturday or Sunday. The goal isn’t just to get boxes out the door quickly, but it’s to control when they land on the customer’s doorstep, ideally when someone is home to receive and refrigerate them immediately.

Managing that level of precision requires data-driven orchestration. Smart operators use order management systems (OMS) paired with their multi-carrier software to balance multiple variables at once—customer preferences, carrier performance by region, delivery service levels, and internal capacity. These tools help spread fulfillment activity evenly across Monday through Thursday, preventing a Monday surge while keeping Friday clear for exceptions and express orders. In cold-chain logistics, a well-timed ship plan isn’t just operational efficiency, it’s product survival.

Picking Accuracy is the Foundation of Cold-Chain Success

Cold-chain subscriptions often involve fewer SKUs than traditional e-commerce operations. While that simplifies inventory management, it also raises the bar for speed and accuracy at scale. In chilled environments, a single mis-pick can lead to costly replacements, chargebacks, and product waste.

Automation gives operators the control needed to eliminate that risk. Systems like VelocityPick™ use pick-to-light technology and real-time tracking to maintain precision. Clear visual indicators guide each operator to the correct bin location and quantity, allowing teams to rotate product and change SKUs without memorizing layouts. These systems also track individual picking accuracy – vital for training, accountability, and continuous improvement.

Lot number tracking is also critical in food fulfillment, and pick-to-light systems can be configured to associate SKU locations with their corresponding lot numbers to maintain full traceability when inventory rotates. By integrating pick data through StreamTech’s WCS, warehouses can sync data across picking, verification, and inventory status with their WMS (Warehouse Management System).

Vision systems such as PackSight™ add another layer of accuracy. Modern camera-based tools can capture an image of every open carton, using machine learning to verify contents and tie each image to an LPN for easy traceability. Combined with checkweigh verification (comparing actual vs. expected weights), these technologies create a closed loop of confirmation from picking to shipping.

Personalization Turns Shipments into Relationships

Subscribers crave order personalization. It’s what transforms a monthly shipment into an ongoing relationship. Studies consistently show that customers prefer to build a genuine connection with the brands they buy from. Many see the brands they subscribe to as an extension of their own personal identity – their values, routines, and even lifestyle choices. This connection fuels what marketers call brand power – the influence a brand holds over customer loyalty and long-term purchasing behavior. In the subscription world, that power is earned through authenticity and personalization.

For cold-chain providers, this emotional connection directly impacts retention. Customers are far more likely to stay loyal and renew when the order feels uniquely theirs, whether it’s a meal kit tailored to a family’s dietary needs or a pet food blend matched to a dog’s health profile. When every box feels thoughtfully packed “for me,” loyalty follows naturally.

Through document automation, businesses can personalize every touchpoint at scale – custom packing slips (“Bruce’s food just left the kitchen”) or dynamic marketing inserts that reflect seasonal preferences, rewards points systems and/or personal milestones such as birthdays or subscription anniversaries.

Value-added experiences, like telehealth access for pet owners or surprise freebies for long-term subscribers can be seamlessly integrated through insert feeders and workflow automation. This approach keeps fulfillment efficient while maintaining that human sense of care that strengthens brand power, and keeps customers coming back.

Packing for Precision

In cold-chain operations, packaging directly affects both temperature control and profitability. Every ice pack, liner, and layer of insulation impacts weight, cost, and compliance. Finding the right balance is critical – too little protection risks spoilage, while too much adds unnecessary cost and shipping surcharges.

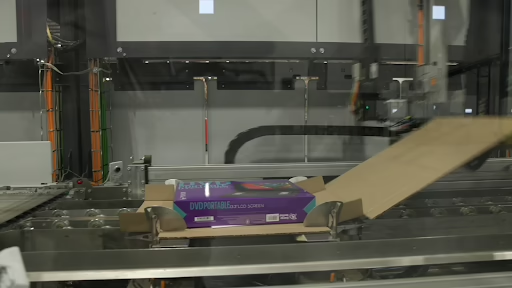

Automation introduces the control necessary to manage those variables. Systems like the Sprinter™ automatically weigh and dimension each carton, apply the shipping label, and verify before heading downstream to sortation. Integrated checkweigher data confirms that each carton’s packed weight aligns with order expectations. When a package deviates out of the expected range – whether from a missed SKU, excess ice, or incorrect packaging – this triggers the system to divert down a quality lane for further inspection.

It’s not uncommon for box weights to climb as temperatures rise, and packers tend to pack more ice indiscriminately. While understandable, those extra pounds can push shipments over carrier weight thresholds and result in fines. An end-of-line checkweigher provides a safeguard, verifying each carton’s weight before it’s manifested and ensuring every order remains compliant and cost-efficient.

Consistent packing also defines the customer experience. Meal kits, for example, require strict sequencing—frozen items on the bottom, produce and instructions on top. While this precise packaging process still requires a human touch, semi-automated systems such as carton erectors, tapers, and visual work aids can make a significant impact. Even simple enhancements like digital displays showing the required quantity of ice or relay switches that advance cartons once ice steps are complete can help packers maintain accuracy, speed, and consistency.

Staying Ahead of the Clock

Shipping timing and operational control define success in cold-chain logistics. Unlike apparel or electronics, perishables can’t linger on a dock, in a trailer, or at a carrier hub for long. Every hour in transit affects freshness, compliance, and customer satisfaction.

As subscription volumes grow, manual processes struggle to keep up. Small inefficiencies compound—one picking error multiplies across hundreds of boxes, and one inaccurate weight can trigger thousands in chargebacks. That’s why timing, visibility, and scalability must work together.

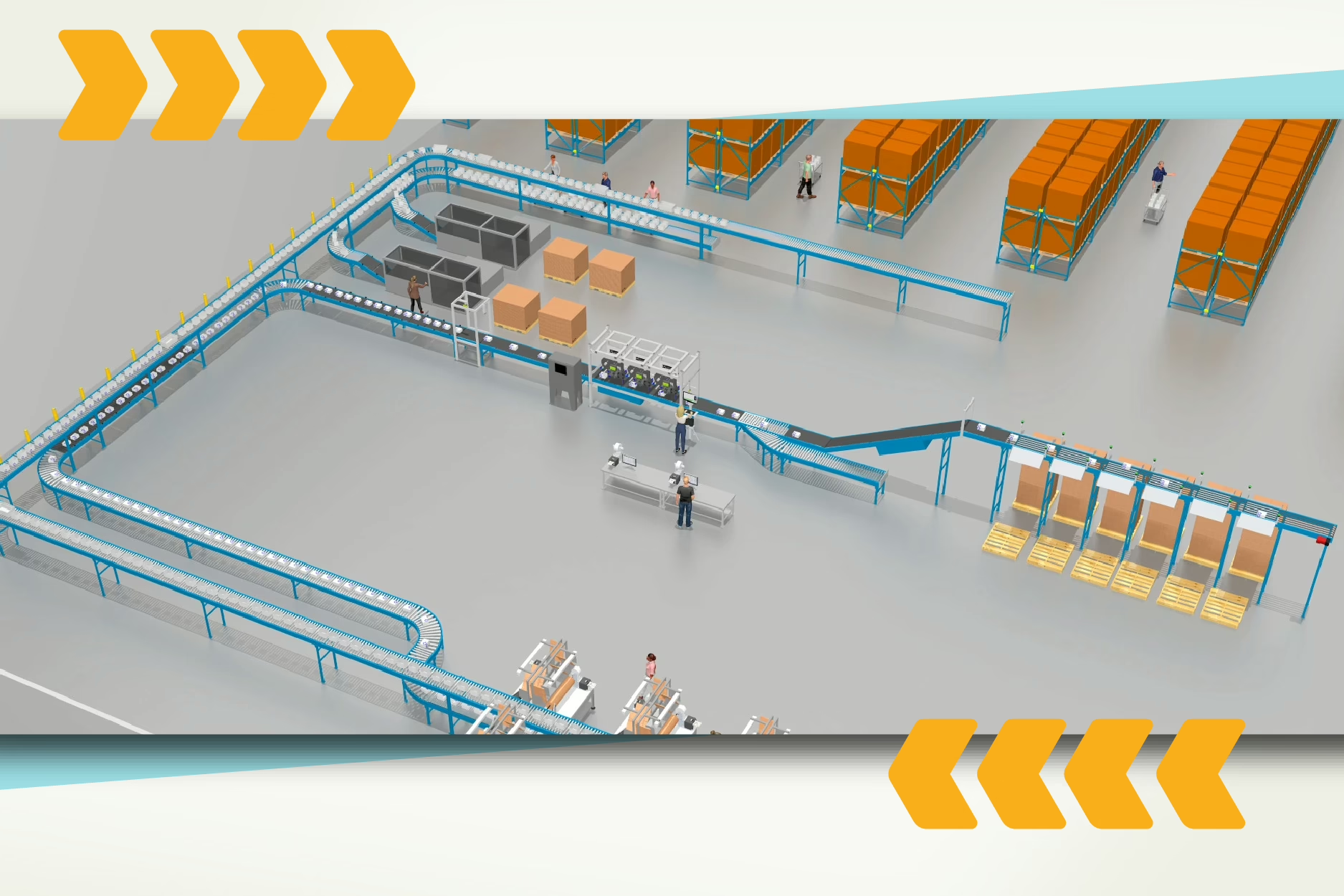

StreamTech’s Warehouse Control System (WCS) brings order to that complexity. By connecting scanning, weighing, dimensioning, and labeling systems into one orchestration layer, it provides real-time visibility from intake through ship confirmation. Each box can be traced, audited, and verified—critical for cold-chain compliance documentation and carrier billing accuracy.

When paired with an OMS or WMS, these systems can use live carrier data to plan shipping cutoffs based on ZIP codes, regional weather events, and transit times. If a storm or heat wave threatens, orders can be automatically held or released early to protect product integrity. Together, these integrations turn what used to be guesswork into a predictable, data-driven shipping process that scales effortlessly with growth.

Automation in Action: Turning Complexity into Consistency

Cold-chain subscription logistics isn’t just about moving boxes, it’s about maintaining trust. Every order represents a promise of safety, freshness, and reliability.

StreamTech’s automation suite delivers on that promise. From VelocityPick™ for rapid order assembly, to Sprinter™ for precision weighing, dimensioning, labeling, and verification, to the WCS that orchestrates it all, our technology connects every step into a single intelligent system.

The result:

- Reduced spoilage and carrier chargebacks

- Smoother weekly order volume

- Consistent, compliant customer deliveries

- A scalable, data-backed foundation for growth

Automation isn’t just efficiency, it’s the infrastructure of reliability.

Key Takeaways

- Timing matters most: Cold chain operators plan around carrier schedules to prevent weekend delays and ensure deliveries stay fresh.

- Accuracy protects quality: Pick to light systems, lot tracking, and vision tools maintain precision and full traceability for every shipment.

- Personalization improves retention: Automated inserts and tailored packing slips help brands create meaningful connections with subscribers.

- Packaging impacts profit: Automated weighing and verification systems balance protection, cost, and compliance for each order.

- Visibility creates control: A unified warehouse control system connects all automation tools for real time insight and smarter planning.

- Automation supports reliability: StreamTech technology transforms complex fulfillment challenges into consistent, scalable performance.

Ready to Automate Your Cold Chain Logistics?

If your subscription model depends on freshness, timing, and customer trust, StreamTech can help you design automation that keeps every box on schedule and in perfect condition.