Trends

Explore Insights, Tools, and Answers

Stay informed with the latest in shipping automation and logistics. From expert articles and upcoming events to product videos and helpful FAQs, our resource center is here to support your operations and keep you ahead of the curve.

-

Trends

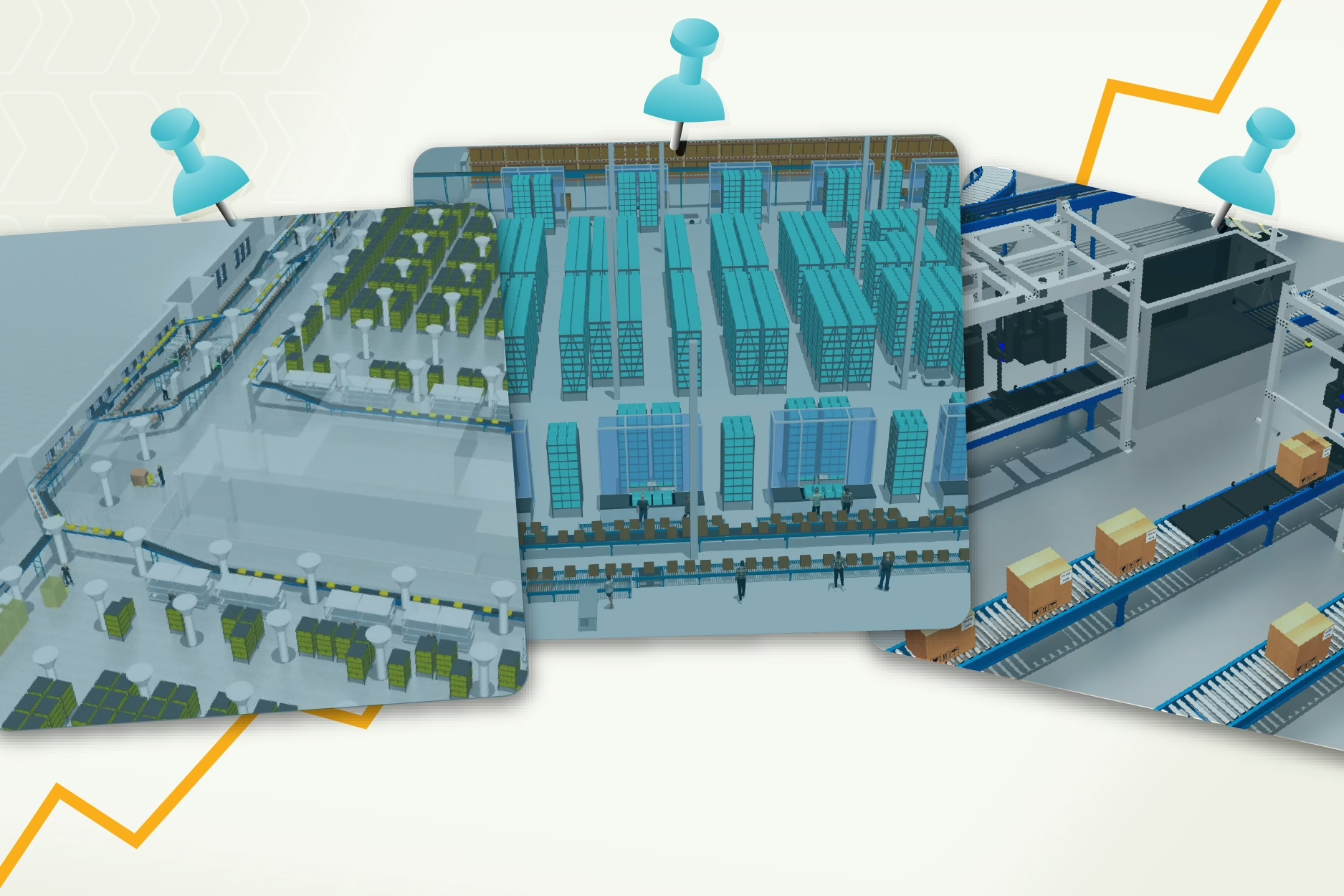

TrendsWarehouse Fulfillment Automation Trends To Watch In 2025

-

Trends

Trends3 Unexpected Ways Automating DIM Weight Controls Costs

-

Trends

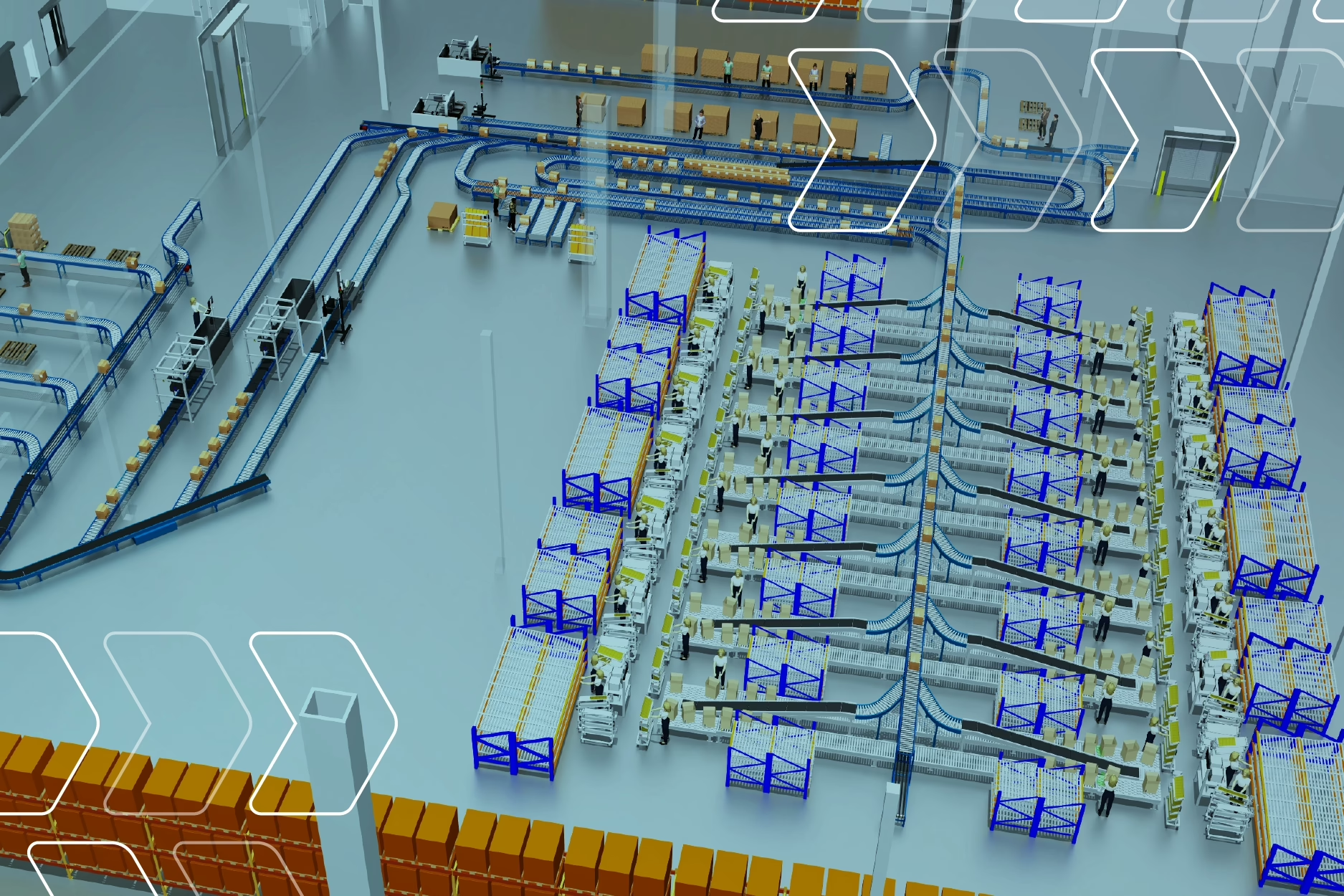

TrendsPersonalized Order Fulfillment Is The Future Of E-Commerce Customer Experiences

-

Trends

TrendsCarriers Are Charging By Dimweight – Here’s Why That Matters

-

Trends

Trends6 Signs You Should Invest In eCommerce Fulfillment Automation

-

Trends

TrendsFour Ways The IOT Is Changing The Face Of Fulfillment

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields