Healthcare & Medical Fulfillment

Material handling solutions for medical supplies, surgical instruments, prescription drugs.

When Accuracy and Safety Matter Most.

For medical and healthcare organizations, precision and speed in order fulfillment aren’t just operational goals—they’re essential to patient safety. Automation minimizes human contact, accelerates processing, and significantly improves accuracy.

In a highly regulated industry where traceability and compliance are non-negotiable, automated systems provide the consistency and transparency needed to meet strict standards and protect patient health.

What Problems Can Automated Fulfillment Solve?

Smart Software Provides Traceability

StreamTech’s light WCS software passes data between the automation hardware and your order database, in real-time, so you always have the most accurate data for reporting and compliance purposes.

Easily Handle Regulatory Documents

Inserting product documentation, regulatory certificates, controlled material data sheets, packing lists, and other information can be automated into each carton, with verification of each page, and parity checking against the order.

Error-Free Fulfillment

Order accuracy for healthcare-related companies is paramount. Automation systems are a perfect fit – using scanners, barcodes, cameras, and verification parity checking at every stage, ensuring nearly 100% accuracy prior to shipment.

Prepare for Growth, Scalability

Using automated picking and packing processes can allow the business to scale with growth, requiring fewer team members for each task. Right-size packaging and cartonization will also reduce shipping costs.

Faster Fulfillment, at Lower Cost Per Order

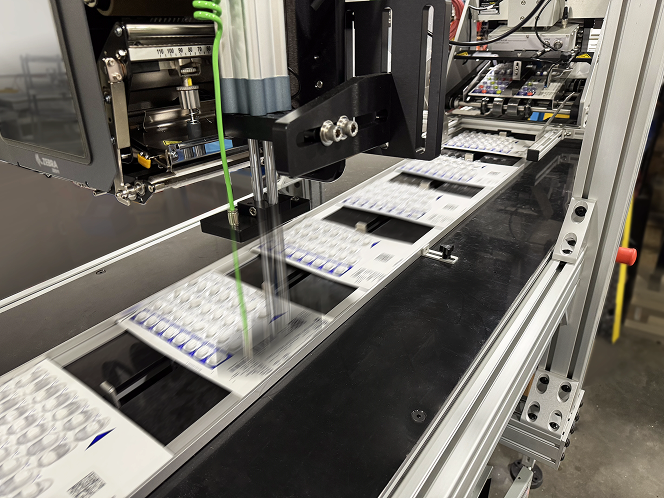

Automating the end-of-line shipping labeling processes gives you a consistent operational speed, regardless of order flow. It also allows you to perform carrier and service-level rate shopping based on the most efficient prices, cutting costs.

Fewer Human Touches

In addition to reducing labor and associated costs and increasing accuracy, employing automating is advantageous for healthcare and medical device companies to reduce the potential for contamination of the products within each order.

See How Fulfillment

Automation Has

Impacted Our Clients

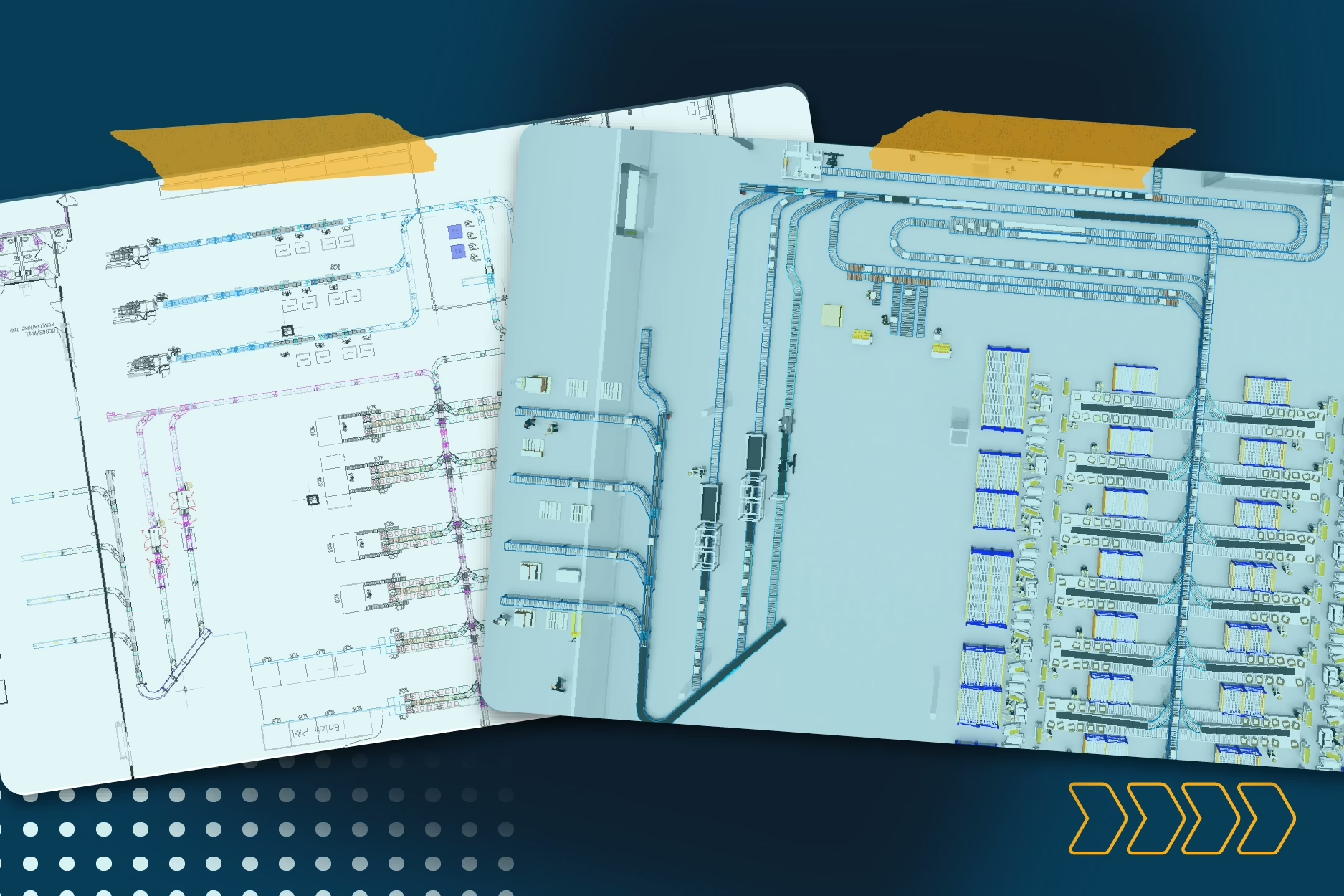

Rotech Healthcare’s new automation accomplishes their goal of lowering costs, optimizing labor, increasing throughput and daily order capacity. The addition of new multi-carrier shipping automation improves their Return On Investment (ROI) further and puts them in more control of their costs.

Your Smart Warehouse Starts Here

From pill packets to medical equipment, StreamTech builds fully automated warehouse solutions designed for the precision and compliance demands of health and medical fulfillment. Improve traceability, reduce handling errors, and keep sensitive products moving safely and efficiently through every step of the process.

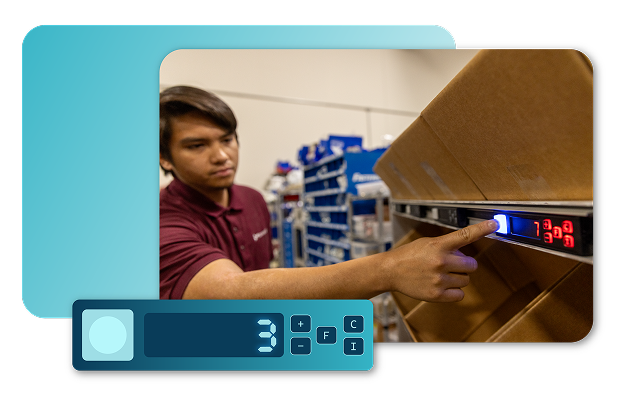

Ensure Orders Are Picked Accurately, and Quickly

StreamTech’s VelocityPick carts have improved picking for many companies in the medical space.

Pickers can batch pick multiple order simultaneously using a pick-to-light equipped smart cart. The cart will be filled with empty cartons, each representing an order with its own ID. The software provides tracking by picker, SKU and LOT number as well.

Easily Add Regulatory Paperwork to Every Order

Insert certificates, packing slips and other documentation without slowing your operation.

Product documentation, regulator certificates, controlled material data sheets, packing lists and other information can be automated into each carton, with verification of each page, and parity checking against the order.

Pack and Ship Orders Consistently Every Time

No matter the day, you can count on end-of-line automation to operate at a certain rate.

Consistent, reliable fulfillment processes give you the ability to coordinate the timing of your orders precisely, to meet customer expectations and avoid shipping bottlenecks.

The Data You Need to Maintain

Traceability and Compliance

Our WCS software monitors the flow of orders through your warehouse, reporting to you.

StreamTech’s light WCS software acts as the intermediary system between the hardware automation equipment, the control system, and your order database. Ensuring you always have the data you need to monitor production, and regulatory compliance.

End-to-End Warehouse Fulfillment & Distribution Automation Solutions

We offer a suite of automation technologies designed to streamline your warehouse operations—from picking and packing to labeling and shipping. Our systems help you move and track products efficiently, reduce manual labor, and increase accuracy at every step of the fulfillment process.

Frequently Asked Questions

If you have any further questions, please reach out to us and we will be glad to help.

How does StreamTech support compliance with healthcare regulations?

We design systems that support traceability, accurate labeling, and the secure handling of sensitive medical products. Our automation integrates with your regulatory workflows—helping you maintain FDA, DEA, or HIPAA compliance depending on your product type and fulfillment model.

Can your systems handle both medical equipment and small-format items like pill packets?

Yes. Our automation solutions are built for flexibility. Whether you’re fulfilling kits, shipping bulk medical supplies, or processing lightweight pill packets, we tailor the solution to your SKUs—ensuring precision across a wide range of product sizes and formats.

How do you reduce human error in sensitive medical fulfillment operations?

By automating repetitive and high-risk tasks like scanning, labeling, paperwork inclusion, and sorting, we reduce the chances of mistakes that could impact safety or compliance. Our software provides real-time verification, order validation, and audit trails for every step.

Can your systems automate the inclusion of regulatory paperwork with outbound orders?

Absolutely. We can configure systems to automatically pair the correct regulatory documentation—such as instructions for use, MSDS sheets, or compliance slips—with each order. These documents can be inserted, printed, or scanned into the workflow as needed.

Our systems track every item through the fulfillment process using barcode scanning, integrated software, and optional image-capture validation. This creates a full digital audit trail, so you can verify that every order was packed correctly and meets regulatory documentation standards.

Is your automation scalable for high-growth or high-volume environments?

Yes. Many of our clients in the medical space have experienced rapid growth, and our systems are built to scale with you. We focus on modular designs and software-driven workflows that can expand as demand increases—without compromising speed or accuracy.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields