High Speed In-Motion Shipping

Engineered for high volume.

Scan, weigh, dimension and label in motion, from 12k to 40k orders daily.

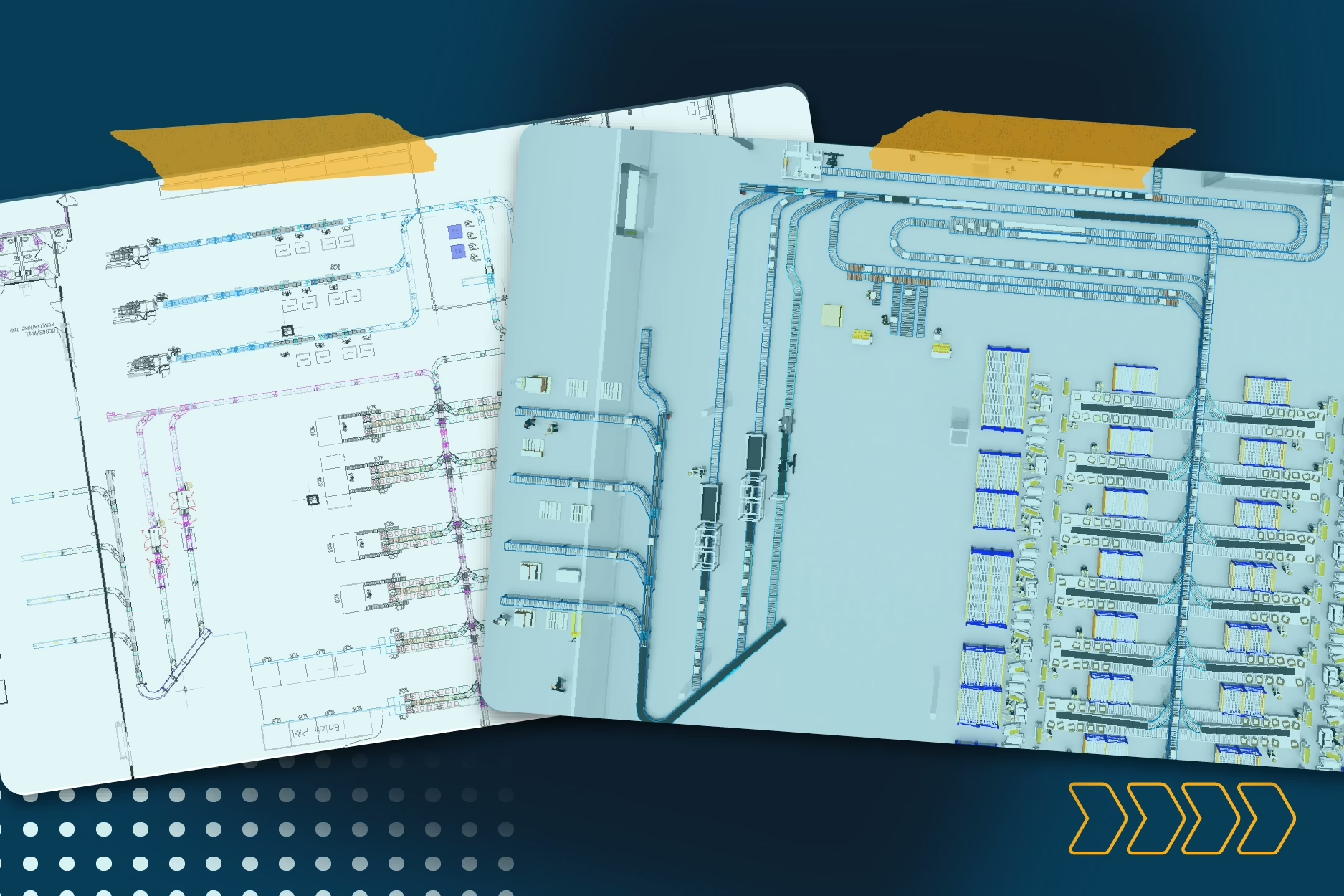

Handling the tasks of end-of-line shipping automation in motion is an entirely different animal. These types of systems allow for multiple labelers in series, high speed belted conveyor, but also require a more detailed approach to the Engineering.

Watch it in Action:

What Makes In-Motion Systems Different?

Higher Speed Labeler

In-motion systems require a fast, responsive labeler equipped with feedback sensors. Our labelers apply light pressure for precise label placement, then retract instantly—keeping up with rapid throughput without damaging the product.

Encoded, Belted Conveyor

Instead of accumulation conveyor, in-motion systems use high-speed belted conveyors with encoded tracking. Each package is gapped precisely and tracked in real time to ensure accurate sequencing and data association.

Low-Latency Software Response

Even the fastest hardware can fall behind if software can’t keep up. Our WCS is optimized for ultra-low latency—processing label data, scale read, and sortation logic in real time to keep everything in sync.

In-Motion Scale

Packages are weighed dynamically as they move—no stopping required. In high-speed environments, multiple labelers can be placed in series to ensure every package is labeled without slowing the line. Real-time weight data flows directly into the WCS to generate accurate labels for each order, even at peak throughput.

Built for Growth

The way in-motion systems are designed, once the packages are singulated and inducted on the high speed belt, multiple labelers can be situated in series to increase the throughput. This makes the system easy to scale with your growth. Add one, two, three, four labelers and see approximately 20/40/60/80 CPM respectively.

Faster Upstream or Downstream Processes

In-motion shipping systems require a higher level of throughput from the surrounding equipment. Typically this means upstream carton erecting equipment, and downstream high-speed sortation.

Our Software & Controls Platform

Intelligent Warehouse Control System (WCS) Software

StreamTech bundles our operational and maintenance know-how in the onboard software app that comes on the included Windows Pro 64-bit SSD PC, with rich functionality that supports troubleshooting and enhances uptime. The intelligent warehouse control (WCS) software easily integrates with rules-based multi-carrier systems or direct carrier interfaces.

- Extensive troubleshooting built-in to the system

- Smart filtering of label files

- Expandable for growing customers

- Rich scan, production, and maintenance statistics with configurable retention

- Server-based thin client solutions are available

- Backup UPS included protecting PC and SQL database

- Multi-level security, multi-user login

Integrated Controls Hardware

StreamTech designs, builds, and installs the control panel to match up with your WCS software and integrated automation hardware.

Machine control is provided by an Allen Bradley PLC, which is easily expandable to manage additional automation. Its open architecture means that end users are able to support themselves if desired.

- Add diverters, merges, etc.

- Open, standard PLC architecture

- All devices IP-addressable for instant world-class support

- Easily modified and expanded; can be extended to low cost system control of reseller conveyor equipment

- EWON remote support router included (no VPN needed)

What our customers say

Frequently Asked Questions

If you have any further questions, please don’t hesitate to contact our customer support team for assistance.

An in-motion system scans, weighs, dimensions, and labels packages as they move continuously down a conveyor—no stopping required. It’s ideal for high-volume operations that need speed without sacrificing accuracy.

Our in-motion systems are engineered for high throughput and can process 60+ cartons per minute, depending on the application and system configuration. They’re designed to keep up with demanding fulfillment schedules.

Our systems combine best-in-class print and apply technology, multi-sided scan tunnels, and smart software controls to ensure accuracy, reduce mislabels, and eliminate bottlenecks—even with complex shipping requirements.

Our software platform tracks every package in real time, handles rate shopping and verification, and integrates directly with shipping servers and carrier APIs. It ensures every label is accurate and every package is accounted for.

Packages that don’t meet verification criteria—due to unreadable barcodes, label issues, or address errors—are automatically diverted for exception handling. This keeps your mainline running smoothly without delays.

Featured Articles

-

Best Practices

Best PracticesWhy the Best Material Handling Solutions Begin with the Right Questions

In today’s high-pressure fulfillment world, it’s tempting to “just get a quote” and keep things moving. But when it comes to automation, fast answers…

Ready for Automation?

Share your fulfillment challenge with us and we’ll design a custom solution for your business before you sign a contract

"*" indicates required fields