Start Your Free Project Assessment.

At StreamTech, we offer a free project assessment to guide your decision-making and provide ongoing support from our responsive team. We collaborate closely to solve your unique warehouse challenges with practical, tailored solutions designed to meet your ROI goals and ensure a smooth process.

"*" indicates required fields

Our Project Design Process:

What to Expect:

Our Solutions and Applications Engineering Team will work with you to specify and design a system to meet your goals. We help identify the correct pain points, study your processes, and learn more about your business.

Below are some of the steps we take as we collaborate with you on a system. Many of these steps may take multiple iterations before a final concept is reached.

01 ⟶

Virtual Meeting

We typically will host an initial virtual meeting where we can get an understanding of your project goals and learn a bit about your operation, and begin gathering some data points.

02 ⟶

Data & Discovery Phase

After the initial meeting, we often get data points such as throughput, package sizes, and master data. We also may ask for photos, video or a drawing of your existing warehouse layout.

03 ⟶

Initial Concepting

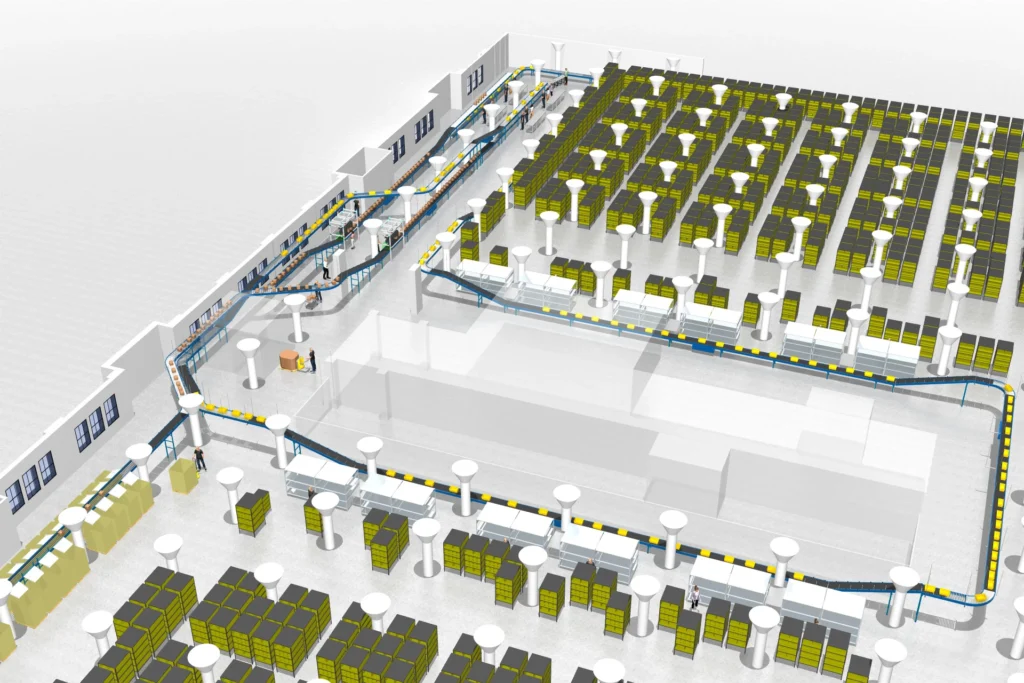

Our Applications Engineers will develop a drawing concept that is intended to meet your design criteria. We will collaborate with you to help refine this and provide budgetary pricing.

04 ⟶

Site Visit

At some point in the process, we will typically schedule a trip to visit your facility. We will take pictures, measurements, and get a better understanding of your process and pain points.

05 ⟶

Concept Refinement

Once we all agree on the general concept and have a solid understanding of the solution, we will refine the concept into a drawing, showing the various options and configurations.

06

Engineered Proposal

Our team develops a detailed proposal that explains the design, how we arrived at it, and how it will work. With pricing and the drawing concept enclosed.

Partner with the Experts in Fulfillment Automation

For over 18 years, our team has worked hard to provide efficient, intelligent fulfillment automation integration to help our customers achieve their business objectives and be more competitive in the evolving eCommerce environment. Whether increasing throughput, optimizing labor, reducing costs, improving customer satisfaction, or being more competitive — the right automation can help.

What our customers say